DC connectors in solar PV systems are a leading cause of fires and performance failures, with studies showing that 40% of urgent safety issues in distributed generation systems relate to connector problems. With nearly 3.5 billion PV connections installed worldwide as of 2021, understanding and mitigating these risks has become critical for system safety and reliability.

PV connectors serve as essential electrical connection points between solar modules, inverters, and other system components. However, these same connection points represent significant potential failure points due to three primary factors: lack of universal standardization, workmanship errors during installation, and incomplete industry data on failures. The 2020 NEC 690.33(C) code revision specifically addresses these concerns by requiring that mismatched connectors be listed and identified for intermateability.

This guide examines the scope of DC connector risks in photovoltaic systems, explains the root causes of connector failures, and provides actionable strategies for reducing these risks through proper installation practices, material selection, and quality control procedures.

Understanding the Problem

Recent studies from reputable research organizations have revealed the frequency and severity of photovoltaic connector problems. The statistics prove noteworthy.

Research indicates that as of December 2021, nearly 3.5 billion PV connections existed worldwide, with connectors identified as a leading cause of fires initiated by PV systems across many global solar markets.

Independent assessments of hundreds of distributed generation systems in the United States found that over half of inspections revealed safety issues requiring urgent correction. Among these urgent issues, 40% related to field-made or factory-made connectors.

In summary, PV connectors remain ubiquitous in photovoltaic systems with no signs of disappearing. Connectors prove simultaneously essential to PV system operation while representing among the largest risks to system performance. In this scenario, connection points and potential failure points become synonymous terms. The root causes of connector issues, however, involve more nuanced factors.

Examining the Context

Understanding the scale of the problem requires examining common causes. Before diving into specifics, several larger forces merit consideration as they impact PV connector issues.

Incomplete Industry Data

Many fires and performance failures remain unreported or underreported due to data sensitivity. Asset owners may hesitate to share site details or initiate legal action. Installers may avoid publishing information that could expose workmanship issues. The solar industry at large may prefer keeping data that reflects negatively on renewables confidential. Competing factors often outweigh incentives to share information on system failures. This situation means operations continue with limited information, requiring extrapolation from available knowledge. Several issues clearly impact PV connector failure rates.

Lack of Standardization and NEC 690.33(C) Requirements

No universal connector exists, despite the 2020 and 2023 NEC requiring UL 6703 listing for connectors identified for intermateability:

2020 NEC 690.33(C) states that where mating connectors are not of identical type and brand, they shall be listed and identified for intermateability, as described in manufacturer instructions.

The 2020 NEC clarifies that cross-mating connectors no longer meets code compliance. Compliance becomes possible through connectors of identical type and brand or by using jumpers, which effectively doubles potential failure points in the system.

The third compliance option, installing UL 6703-listed connectors, remains theoretically possible but practically infeasible. Field installations must comply with product listing instructions per 2020 and 2023 NEC 110.3(B), meaning installation manuals supersede UL listings. Assembly instruction documents from leading connector manufacturers contain warnings similar to:

“Do not connect the male or female part of this connector with connectors of other manufacturers.”

According to connector manufacturers themselves, a universally compatible connector does not exist. Similar to how incentive structures can discourage data sharing about system failures, market forces oppose connector standardization. If a manufacturer were to pay for listing its product as universally compatible, it would effectively make the product interchangeable with competitors and potentially reduce market share.

Workmanship Errors

Of the estimated 3.5 billion PV connections worldwide, human technicians installed the vast majority. Most developers and installers maintain rigorous in-house standards and training programs. However, limited industry-wide knowledge exists regarding PV installation and maintenance best practices. Given that seemingly small installation errors can cascade into more significant issues, sharing expertise to improve workmanship quality benefits all parties involved.

Strategies to Decrease Risk

As the entire PV industry awaits a universal connector, several immediate steps can reduce risks associated with connector failure.

Enhance Training Procedures: No simple solution exists to resolve workmanship errors, especially during periods of high demand with a relatively undersized workforce. However, investing in workforce development and consistently updating installation and maintenance processes remains strongly recommended. Third-party training providers offer alternatives when teams face budget or personnel constraints. Establishing recurring operational reviews validated with system performance metrics proves beneficial. Gradual steps accumulate into significant long-term impact, ultimately improving customer satisfaction.

Optimize Bill of Materials: Avoid risks associated with connector mismatch by specifying modules and any MLPE with intermateable connectors early in development. Collaboration with distributors helps identify the right equipment specifications, with readiness to make adjustments as needed. Understanding regional permit requirements can also inform material selection decisions.

Refine Installation and O&M: With dozens, hundreds, or even thousands of PV connectors per site, numerous opportunities for installer error exist. Minimize risk by building detailed yet replicable processes and maintaining high installer standards. For example, one common mistake involves leaving connectors staged but unattached during installation, allowing debris and moisture entry. Avoiding this requires capping all connectors until ready for connection. Proper solar permitting procedures should account for these installation protocols.

Use the Right Tools: Though obvious, using appropriate tools correctly when installing PV connectors proves essential. Each manufacturer specifies particular tools and installation requirements, including torquing specifications, in assembly instructions. Failure to follow these instructions can result in damaged or improper connections.

Trust But Verify: Quality assurance and quality control serve as the ultimate backstop for early issue detection. Verify connector health after shipping or other transport. Test connector circuits for electrical continuity before commissioning. Perform routine maintenance checks post-installation, including thermal imaging, to identify hot spots that may indicate improper or damaged connections. Professional solar services can help establish comprehensive QA/QC protocols.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Conclusion

PV connectors serve as critical components in photovoltaic systems, yet they simultaneously represent one of the most significant safety and performance risks. With nearly 3.5 billion connections installed worldwide and connectors identified as a leading cause of PV system fires, addressing these risks demands immediate attention. The challenges stem from multiple factors including lack of universal standardization, workmanship errors during installation, and incomplete industry data on failures.

Moving forward requires a multi-faceted approach. Enhanced training programs, optimized material specifications, rigorous quality control procedures, and adherence to NEC 690.33(C) requirements all play essential roles in reducing connector-related failures. While the industry awaits a universal connector standard, implementing these practical strategies can significantly decrease risks and protect both system performance and personnel safety. Whether working on residential installations or large-scale commercial projects, understanding connector risks remains fundamental. For comprehensive guidance on solar permit requirements and system compliance, Solar Permit Solutions provides expert support throughout the design and approval process.

Through collective commitment to best practices and continuous improvement, the solar industry can build more reliable and safer photovoltaic installations for the long term.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

NEC 690.33(C) is a code requirement introduced in the 2020 National Electrical Code that addresses PV connector mating and intermateability. This section requires that connectors not of identical type and brand must be listed and identified for intermateability according to manufacturer instructions. This matters because improperly matched connectors can lead to system failures, fires, and safety hazards. The requirement essentially prohibits cross-mating connectors from different manufacturers unless they are specifically tested and certified as compatible. Understanding these solar permit requirements is essential for compliance.

No, even if connectors from different manufacturers physically connect, this does not make them code-compliant or safe. Different manufacturers use varying materials, metal compositions, dimensional tolerances, and ratings. These differences can cause increased resistance, overheating, arcing, and eventual failure. To remain compliant with NEC 690.33(C) and ensure system safety, use connectors of identical type and brand, or verify that connectors are specifically listed for intermateability in manufacturer documentation.

The most common causes include workmanship errors during installation, such as improper crimping or inadequate torquing of connections. Environmental factors like moisture intrusion and debris contamination also contribute significantly to failures. Additionally, mixing incompatible connector brands creates stress points that lead to increased resistance and heat buildup. Leaving connectors uncapped during installation allows contaminants to enter, while failing to follow manufacturer assembly instructions results in compromised connections that degrade over time. Many of these issues can be prevented through proper permitting procedures and quality control.

Regular thermal imaging inspections provide the most effective early detection method, revealing hot spots that indicate high resistance or poor connections. Visual inspections should check for physical damage, discoloration, melting, or corrosion on connector housings. Electrical continuity testing before commissioning verifies proper connections throughout the system. Additionally, monitoring system performance data for unexpected drops in output can signal connection issues. Implementing a routine maintenance schedule that includes these inspection methods helps catch problems before they escalate into safety hazards or system failures. For residential solar systems, regular monitoring becomes even more critical.

First, document the locations and types of mismatched connectors found during inspection. Priority should be given to replacing connectors in areas showing signs of stress, heat damage, or performance issues. For systems with standard string inverters, purchasing matching connectors or pre-crimped wire whips that correspond to module connectors offers the simplest solution. Alternatively, installing jumper cables with proper connectors on both ends can resolve compatibility issues, though this approach doubles the number of connection points. Regardless of the method chosen, ensure all replacement work follows manufacturer installation instructions and local code requirements. For off-grid installations, proper connector matching is especially critical. Contact our team for professional assessment and remediation guidance, or explore our blog resources for additional technical insights.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

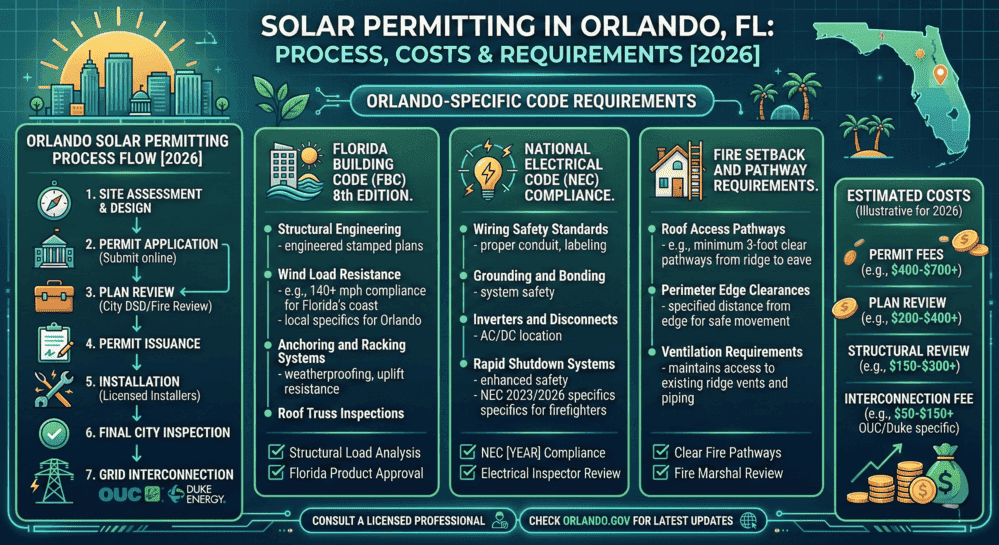

Solar Permitting in Orlando, FL: A Complete Guide for Homeowners & Installers

Solar permitting in Orlando, FL, requires a building permit and an electrical pe...

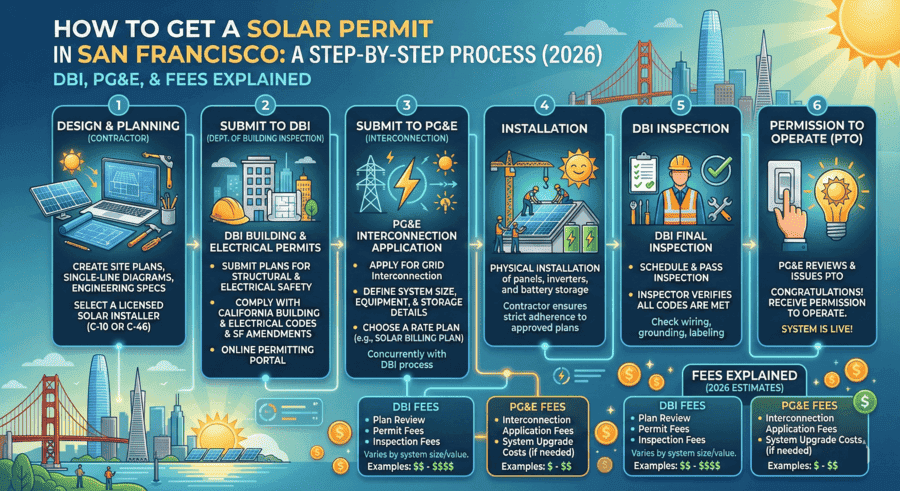

How To Get A Solar Permit In San Francisco: DBI, PG&E And Fees Explained (2026)

San Francisco solar permits require two separate approvals before your system ca...

Bifacial Solar Panel Installation And Permitting Guide

Bifacial solar panels generate 10 to 30 percent more energy than traditional mon...