Solar power system conduit protects electrical wiring from environmental damage, moisture, UV exposure, and physical impacts. The right conduit choice directly affects system safety, longevity, and compliance with National Electrical Code (NEC) requirements.

Without proper conduit protection, wiring faces serious risks: water damage leading to electrical fires, UV degradation causing insulation failure, temperature-related breakdowns, and animal interference. These hazards compromise system performance and create safety concerns that can be costly to repair.

Common conduit types include rigid PVC (UPVC), electrical non-metallic tubing (ENT), rigid metal conduit (RMC), flexible metal conduit (FMC), and fiberglass options. PVC offers UV resistance and corrosion protection, metal conduits provide superior physical protection and grounding capabilities, while fiberglass excels in extreme temperatures.

This guide covers everything from installation best practices to selecting the right type based on your location, climate, and local building codes.

Understanding Solar Photovoltaic Systems

Solar photovoltaic (PV) systems capture sunlight and transform it into electricity through the photovoltaic effect. When sunlight contacts solar panels, it energizes electrons in the semiconductor material (typically silicon) within the panels. This energization produces direct current (DC) electricity, which an inverter then converts into alternating current (AC) electricity, making it compatible with household appliances and the electrical grid.

A solar PV system includes several essential components:

Solar Panels: The most prominent system element, solar panels absorb sunlight and convert it into DC electricity. These panels are typically installed on rooftops or ground-mounted arrays and are available in various types, including monocrystalline, polycrystalline, and thin-film options.

Solar Inverters: These devices convert DC electricity generated by solar panels into AC electricity, the standard form used in residential solar design and commercial settings. Inverters also enhance system performance by regulating energy flow and maintaining efficient operation.

Batteries: In grid-tied configurations, batteries store surplus energy generated during daylight hours for use during nighttime or overcast conditions. They improve solar power reliability by supplying backup energy when sunlight is unavailable.

Wiring: Appropriate wiring connects all solar system components, enabling safe and efficient electricity flow. Conduits must protect the wiring to prevent damage from environmental elements.

The Role Of Conduits In Solar Installations

The primary function of conduit is protecting electrical wiring from damage and environmental hazards. In solar installations, conduits enclose the wiring connecting solar panels to inverters, batteries, and the electrical grid. This enclosure prevents wear and tear that could result in system faults or failures.

Key Functions Of Conduits In Solar Installations

Protection: Conduits establish a physical barrier against various threats, including moisture, UV rays, temperature extremes, and physical impacts.

Organization: They facilitate wire organization and management, minimizing tangling risks and confusion during installation and maintenance procedures.

Accessibility: Conduits enable easier wiring access for future repairs or upgrades, streamlining maintenance tasks.

Protection Against Environmental Hazards

Moisture: Water exposure represents a significant risk for electrical components. Moisture penetration into wiring can cause corrosion, leading to short circuits or electrical fires. Conduits are engineered to be watertight, preventing water intrusion and maintaining dry, functional wiring. This protection is particularly essential in regions experiencing heavy rainfall, flooding, or high humidity, where extended moisture exposure can trigger system failures.

Solar fires often originate from various installation errors and oversights. A major risk involves inadequate protection against water intrusion, which can cause electrical malfunctions. Implementing proper wiring protection enhances waterproof protection, reducing this hazard. Without early detection through effective monitoring or regular inspections, these issues can create significant fire risks.

UV Exposure: Solar installations face constant sunlight exposure. Many conduit types utilize UV-resistant materials that prevent degradation over time. Without this protection, unshielded wires become brittle and lose insulating properties, increasing electrical short and fire risks. High-quality conduits ensure wiring maintains integrity and performance long-term.

Extreme Temperatures: Temperature variations can severely impact wiring performance. In hot climates, excessive heat causes insulation breakdown, leading to overheating and potential fires. In cold climates, wires become rigid and brittle, elevating breakage risks. Conduits provide wire insulation, maintaining stable operating conditions and reducing damage risks from temperature extremes.

Physical Damage: Solar installations face various physical threats, including falling branches, debris, and impacts from heavy equipment. Conduits protect against these risks by providing robust wiring shields, minimizing accidental damage chances and ensuring continued system operation.

Animals present unique threats to solar installations. Birds may perch on solar panels or nearby structures, with nesting behavior potentially causing wire damage. Rodents may burrow and gnaw on exposed wiring. Conduits prevent these incidents by providing protective barriers that deter animal access to vulnerable wiring, reducing costly repair needs and downtime.

Regulatory Compliance Of Conduit Usage In Solar Power Systems

Adhering to electrical codes is essential for ensuring installations meet industry standards. Many local and national regulations mandate conduit use in specific applications to ensure safe wiring practices. Non-compliance can result in fines, increased insurance costs, and potential liabilities from accidents. Proper installation protects users and helps avoid legal issues arising from non-compliance.

The NEC provides essential guidelines for solar PV and energy storage installations, primarily under Articles 690 and 706. Article 690 addresses solar PV system design and installation, specifying requirements for system components such as modules, inverters, and wiring methods. It emphasizes proper grounding, overcurrent protection, and safety measures for DC wiring. Article 706 outlines installation and operational requirements for energy storage systems, including battery types, monitoring systems, and integration with PV systems.

Types Of Conduit For Solar Applications

When selecting conduit for solar applications, choosing options that withstand outdoor environments is crucial. Due to exposure to various weather conditions, conduits used in solar power systems are often designed for greater durability than indoor options or feature protective coatings.

PVC Conduits

Rigid Plastic Conduit (UPVC)

Material: Manufactured from unplasticized polyvinyl chloride (UPVC), which is more rigid than regular PVC due to the absence of plasticizers.

Characteristics:

- Lightweight and easy to handle, reducing labor costs

- Excellent corrosion resistance, suitable for outdoor use and chemical exposure environments

- Smooth inner walls reduce friction, enabling easier cable pulling

- UV-resistant formulations, often enhanced with additives like titanium dioxide, extend service life under sunlight exposure

Electrical Non-Metallic Tubing (ENT)

Material: Typically manufactured from PVC.

Characteristics:

- Flexible, allowing installation in tight or complex spaces without fittings

- Lightweight, reducing installation time and effort

- Moisture-resistant, ideal for wet locations and outdoor installations

- Chemical-resistant, suitable for solar setups with environmental exposure concerns

Metal Conduits

Rigid Metal Conduit (RMC/ENT)

Usually constructed from galvanized steel, though aluminum variants are available for specific applications.

Characteristics:

- High strength and durability, providing excellent physical damage protection

- Corrosion resistance through galvanization; aluminum offers natural corrosion resistance

- Conductive, suitable for electrical system grounding

Flexible Metal Conduit (FMC)

Made of steel, often galvanized for corrosion resistance.

Characteristics:

- Provides flexibility for easy routing around obstacles and through tight spaces

- Offers adequate physical damage protection while remaining lightweight

- Conductive, allowing grounding and bonding applications

Fiberglass Conduits

Comprised of glass fiber reinforced plastic (FRP), combining glass fibers with thermosetting resin.

Characteristics:

- Extremely lightweight yet strong, facilitating easy installation

- Excellent corrosion and UV radiation resistance, ensuring outdoor application longevity

- Withstands extreme temperatures, often rated from -60° to 250° F

Specialized Conduit Options

Low Smoke Halogen-Free Conduit

Typically manufactured from specialized PVC or thermoplastic elastomers designed to emit low smoke and no halogens when burned.

Characteristics:

- Reduces toxic emissions during fires, enhancing safety in occupied buildings

- Flexible and easy to install, similar to traditional PVC conduits

Conduit With Protective Coatings

Often metallic conduits coated with plastic, epoxy, or polyurethane layers.

Characteristics:

- Enhanced resistance to UV rays, moisture, and chemicals due to protective layers

- Extended conduit lifespan in harsh environments

Key Considerations For Choosing Conduit

When selecting conduit for solar installations, several factors influence performance, durability, and safety standard compliance.

Environmental Conditions

UV Resistance: Since solar installations typically face sunlight exposure, choosing conduits made from UV-resistant materials prevents degradation over time. PVC conduit types and fiberglass conduits often provide enhanced UV protection.

Temperature Extremes: Assess the installation site’s temperature range. Fiberglass conduits excel in extreme temperatures, while UPVC conduits may warp under prolonged high heat exposure.

Moisture And Chemical Resistance: For installations in humid or chemically aggressive environments, materials like fiberglass or Electrical Non-Metallic Tubing (ENT) are ideal due to superior moisture and chemical resistance.

Installation Location

Rooftop Systems: These installations face unique challenges including limited space and harsh weather exposure. Lightweight, flexible conduits are preferable for easier handling and installation, allowing efficient routing around obstacles.

Ground-Mounted Systems: Ground-mounted systems may require more robust conduit options capable of enduring soil conditions and potential landscaping activity impacts. Rigid conduits provide necessary durability in these situations.

Specific Needs Based On Geography And Climate

Geographical And Climatic Factors: Consider local environmental conditions when determining conduit specifications. Areas with extreme temperatures need conduits that withstand thermal expansion and contraction, while regions prone to high winds or heavy snowfall benefit from conduits designed for enhanced stability and support. Understanding regional permit requirements helps ensure full compliance.

Flexibility Versus Rigidity

Flexible Conduits (FMC, ENT): These conduits are advantageous in installations requiring bends or tight spaces, making obstacle navigation easier. Their flexibility can reduce additional fitting and joint needs, minimizing potential failure points.

Rigid Conduits (RMC, UPVC): Rigid conduits offer superior physical damage protection and are ideal for straight runs requiring robust support. Choose rigid options in high-traffic areas or locations with potential impacts.

Fire Safety Considerations

Low Smoke Halogen-Free Options: In regions with stringent fire safety regulations, consider low smoke halogen-free conduits, which minimize toxic smoke production during fires, enhancing safety for residential and commercial applications.

Non-Combustible Materials: For installations in densely populated areas or buildings, opt for conduits made from non-combustible materials like metal conduits to ensure fire code compliance.

Cost Versus Performance

Budget Constraints: Evaluate conduit initial costs against long-term performance and maintenance needs. While fiberglass may have higher upfront costs, its longevity and reduced maintenance requirements in harsh environments can justify the investment.

Total Cost Of Ownership: Consider factors like installation complexity, labor costs, and potential future repairs when selecting conduit types.

Compliance With Standards

Local Building Codes: Always verify chosen conduits comply with local building codes and standards, such as the National Electrical Code (NEC) and applicable ASTM standards, to ensure installation safety and reliability.

Manufacturer Certifications: Look for conduits certified for specific applications, such as UL listing or other industry certifications, to ensure they meet rigorous safety and performance standards.

Installation Ease

Weight And Handling: Lightweight conduits like ENT are easier to handle and install, reducing labor time. Heavier options may require more robust mounting systems.

Compatibility With Existing Systems: Ensure chosen conduits are compatible with existing solar system components, such as wiring and connectors, to facilitate seamless installation.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Installation Of Conduit In Solar Panel Systems

When installing conduit for solar panel systems, proper planning and execution are essential for ensuring durability and efficiency. This detailed guide covers recommended tools, materials, routing tips, and more.

Recommended Tools And Materials For Installation

Tools

- Conduit Bender: For creating smooth bends without kinking the conduit

- Pipe Cutter: To cut conduit to required lengths cleanly

- Drill With Bits: For securing conduit and making necessary holes in mounting structures

- Screwdriver Or Impact Driver: For fastening conduit straps and mounting brackets

- Measuring Tape: To ensure accurate lengths and distances

- Level: To confirm conduit runs are straight and properly aligned

- Gloves And Safety Glasses: Essential for personal protection during installation

Materials

- Conduit: Depending on installation environment and local codes

- Conduit Fittings: Elbows, connectors, and couplings to secure and route the conduit

- Conduit Straps: For attaching conduit to mounting surfaces

- Solvent Cement (for PVC): To bond PVC conduits securely

- Wire: For connecting solar panels to inverters and other components, ensuring outdoor-rated specifications

Tips For Efficient Conduit Routing And Minimizing Bends

Plan The Layout: Before beginning installation, sketch a detailed conduit route layout. Identify all solar panel locations, inverters, and junction boxes to minimize unnecessary bends.

Use Straight Runs: Whenever possible, use straight conduit sections to reduce resistance and improve wire pulling efficiency.

Minimize Bends: Each bend adds complexity and can increase resistance. Limit bends to no more than 360 degrees between junction points, using larger radius bends when necessary.

Group Conduits: If multiple conduits are needed, group them together to simplify installation and reduce required mounting points.

Utilize Conduit Supports: Ensure conduits are securely mounted using straps or brackets, spaced according to local code requirements, to prevent sagging and maintain alignment.

Conclusion

Selecting the right conduit for solar power installations is a critical decision that directly impacts system safety, performance, and longevity. The protective pathway provided by quality conduit ensures electrical wiring remains secure against environmental hazards, physical damage, and extreme weather conditions that solar installations routinely face.

Understanding the various conduit types available, from PVC and metal options to specialized fiberglass and low smoke halogen-free alternatives, empowers property owners and installers to make informed decisions. Each conduit type offers distinct advantages suited to specific installation environments, whether rooftop or ground-mounted systems, in diverse climatic conditions.

Key considerations such as UV resistance, temperature tolerance, moisture protection, and regulatory compliance should guide the selection process. While initial costs may vary, investing in appropriate conduit materials ultimately reduces maintenance expenses, extends system lifespan, and ensures compliance with electrical codes and safety standards.

Proper installation techniques, including efficient routing, minimal bending, and secure mounting, further enhance conduit effectiveness. By following manufacturer guidelines and local building codes, solar installations can achieve optimal performance while minimizing risks associated with electrical failures or safety hazards.

The future of solar energy depends on reliable, well-protected systems. Taking time to carefully select and properly install conduit components establishes a solid foundation for solar power systems that will generate clean, renewable energy for decades to come.

FAQs

Inadequate Support: Failing to secure conduit properly can lead to sagging or shifting, potentially damaging wiring. Use appropriate straps and supports at recommended intervals.

Incorrect Bending Techniques: Using improper bending techniques can weaken conduit or create sharp edges that may damage wiring.

Ignoring Condensation Risks: Not considering moisture accumulation in conduit, especially in colder climates, can lead to water damage to electrical components.

Routing: Proper conduit routing creates cleaner, more organized appearances. Neatly bundled or hidden conduits reduce visual clutter and provide more professional looks.

Conduit Fittings Usage: Minimizing visible conduit numbers by using fewer, larger conduits can enhance aesthetics. Using junction boxes or other conduit fittings and combining wiring can help achieve cleaner appearances.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Improper Sizing: Using conduit that is too small can lead to overheating and increased wiring resistance. Always follow NEC guidelines for conduit sizing based on conductor numbers and sizes. Inadequate Support: Failing to secure conduit properly can lead to sagging or shifting, potentially damaging wiring. Use appropriate straps and supports at recommended intervals. Incorrect Bending Techniques: Using improper bending techniques can weaken conduit or create sharp edges that may damage wiring. Ignoring Condensation Risks: Not considering moisture accumulation in conduit, especially in colder climates, can lead to water damage to electrical components.

UV resistance is crucial for solar conduit longevity, especially since these conduits often face direct sunlight exposure. Without adequate UV protection, materials can degrade, leading to brittleness, cracking, and structural integrity loss over time. This degradation can compromise conduit ability to protect wiring, increasing electrical failure or safety hazard risks. Selecting UV-resistant conduit ensures performance and durability maintenance throughout its lifespan, ultimately reducing maintenance costs and early replacement needs.

Visibility: Conduit material and color choices can either blend with or stand out against roofs or surrounding environments. Routing: Proper conduit routing creates cleaner, more organized appearances. Neatly bundled or hidden conduits reduce visual clutter and provide more professional looks. Conduit Fittings Usage: Minimizing visible conduit numbers by using fewer, larger conduits can enhance aesthetics. Using junction boxes or other conduit fittings and combining wiring can help achieve cleaner appearances.

Yes, different conduit types can be combined in the same solar installation, provided proper fittings and transitions are used. For example, flexible conduit might be used near panel connections for easier routing, while rigid conduit protects wiring along exposed runs. However, ensure all transitions between different conduit types are properly sealed and comply with local electrical codes. Each conduit section must maintain appropriate protection levels for its specific location and environmental exposure. Consulting with a licensed electrician or following NEC guidelines helps ensure safe and compliant mixed-conduit installations.

Solar conduit requires minimal but important maintenance to ensure continued protection. Regular visual inspections should check for cracks, degradation, loose mounting straps, or physical damage, especially after severe weather events. UV-exposed conduits should be examined for brittleness or discoloration indicating material breakdown. Check junction boxes and conduit entry points for proper sealing to prevent moisture intrusion. Any damaged sections should be promptly repaired or replaced to maintain wiring protection. Annual inspections are typically sufficient for most installations, though systems in harsh environments may benefit from more frequent checks. Proper initial installation with quality materials significantly reduces long-term maintenance needs.

Working with experienced professionals ensures proper conduit selection, code compliance, and system reliability. Solar Permit Solutions offers comprehensive design and permitting services for residential and commercial projects. Professional assistance helps navigate solar permitting requirements, avoid common permit mistakes, and ensure installations meet all safety standards. Whether planning a rooftop system or ground-mounted array, expert guidance streamlines the process from design through final project approval. Contact our team to discuss specific project requirements and receive professional support throughout the installation journey.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

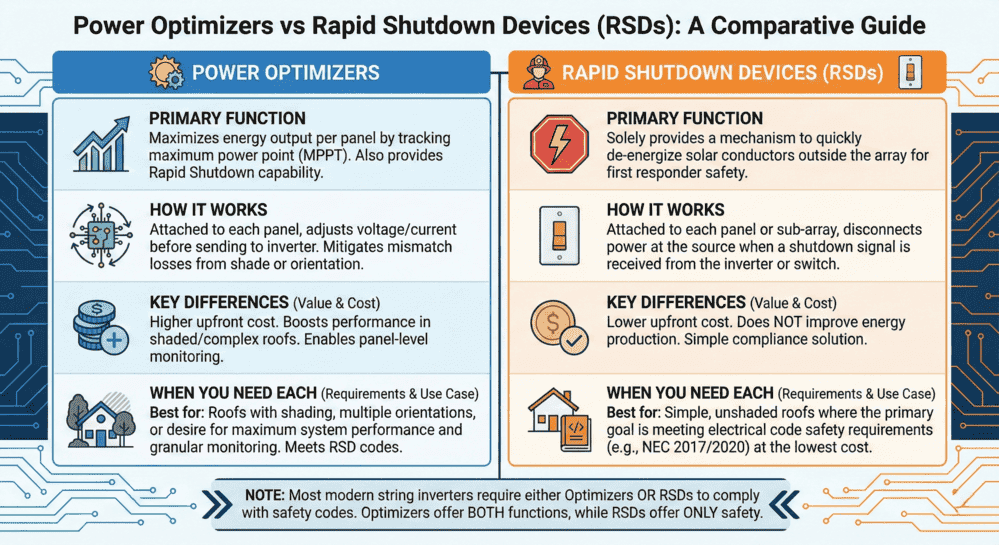

Power Optimizers vs Rapid Shutdown Devices: Differences, Requirements & When You Need Each

When planning a solar installation, understanding the difference between rapid s...

Your Complete DIY Solar Panel Installation Guide

Homeowners turn to solar energy for various motivations. Clean, renewable power ...

What Is A Commercial Solar PV System?

A commercial solar PV system is a renewable energy setup designed to help busine...