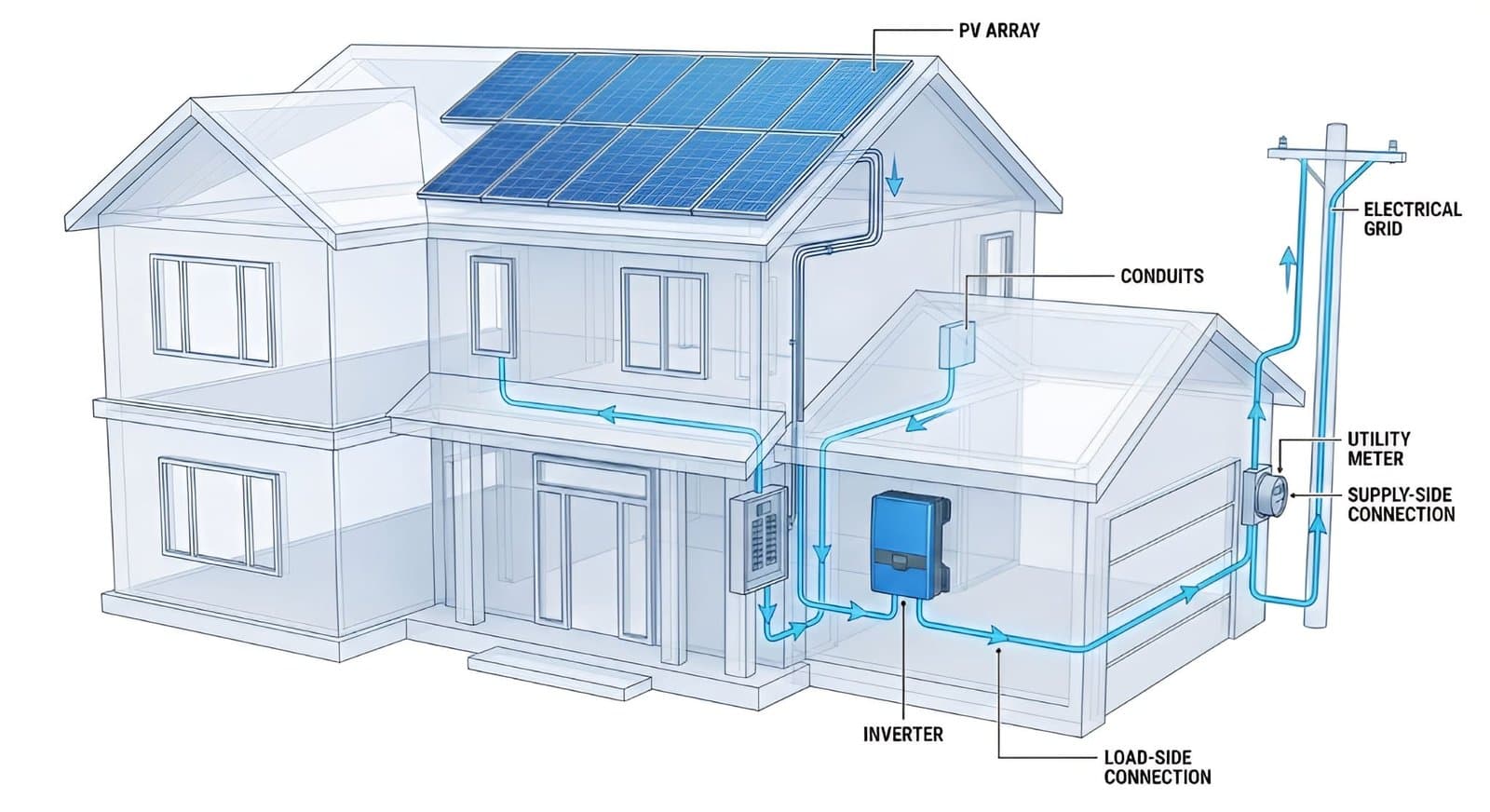

Solar interconnection refers to how a photovoltaic (PV) system connects to the electrical grid through either supply-side or load-side methods. Supply-side interconnection connects before the main service disconnect and is not limited by the 120% rule, making it ideal for systems 15kW to 50kW. Load-side interconnection connects after the main disconnect using a breaker and is the most common method for residential systems 7kW to 15kW, though it must comply with NEC 705.12(B)(2) busbar limitations.

The choice between supply-side (line-side) and load-side (breaker-based) interconnection determines system cost, installation complexity, permitting requirements, and NEC code compliance. Load-side connections offer simpler installation with no service disconnect modifications but are limited by the 120% rule. Supply-side connections bypass busbar limitations and support larger commercial installations but require utility coordination and service entrance modifications.

This guide explains both interconnection methods, when to use each approach, common inspection failures, and design best practices for solar professionals submitting plan sets to authorities having jurisdiction (AHJs).

Understanding Solar Interconnection Methods

Interconnection determines where the solar inverter output (AC side) connects into the existing electrical system, either:

- Before the main service disconnect (supply-side)

- After the main service disconnect (load-side)

Each method presents unique benefits, limitations, and NEC code implications.

Load-Side Connection: Breaker-Based Integration

This is the most common method for residential and small commercial PV systems. It connects the inverter output into the main panel or subpanel using a dedicated breaker.

Advantages

- Simpler installation

- No service disconnect modification

- Easy to design and permit

Challenges

- Must comply with the 120% rule under NEC 705.12(B)(2)

- Limited by busbar rating and main breaker size

For example: If a main panel has a 200A busbar and a 200A main breaker, the total backfeed from solar cannot exceed 40A (20% of 200A).

This means a 40A breaker can be used for PV (approximately 9.6 kW at 240V), unless the main breaker is downsized or a PV subpanel is added.

Supply-Side Connection: Line-Based Integration

In this configuration, the PV output connects ahead of the main service disconnect, directly into the service conductors. This approach is common for off-grid systems transitioning to grid-tied.

This makes the solar system essentially a parallel service source to the utility feed.

Advantages

- Not limited by the 120% rule

- Ideal for larger systems where the main panel cannot handle PV backfeed

- Often used for commercial or high-capacity residential installations

Challenges

- Requires service entrance modifications

- Must comply with NEC 230.82(6) and 705.11

- AHJs and utilities often require utility coordination and sealed metering compartments

- Adds cost and complexity for installation and inspection

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Selecting The Optimal Connection Method

Inspection Issues To Avoid

- PV breaker placed at the top of panel bus (violates 120% rule if not derated)

- Missing tap conductor labeling in supply-side setups

- Utility meter enclosure tapped without utility approval

- Missing or incorrect PDP (Point of Connection) diagram in permit applications

Planning Your Connection Strategy

When determining the appropriate interconnection method, the design should start with a panel schedule review. Key items to check include:

- Busbar rating

- Main breaker size

- Available breaker positions

This analysis helps determine if a load-side connection is feasible or if a supply-side tap design is necessary.

Conclusion

Choosing between supply-side and load-side interconnection goes beyond convenience. It’s about ensuring long-term system safety, passing inspections without redlines, and aligning with NEC standards and utility requirements.

By planning the connection strategy early, costly redesigns can be avoided, permitting time can be saved, and installation teams can stay focused on clean, compliant work.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

The 120% rule, outlined in NEC 705.12(B)(2), limits the total current sources (utility main breaker plus solar breaker) to 120% of the panel's busbar rating. For example, if a panel has a 200A busbar, the combined rating of the main breaker and solar breaker cannot exceed 240A. This rule only applies to load-side interconnections.

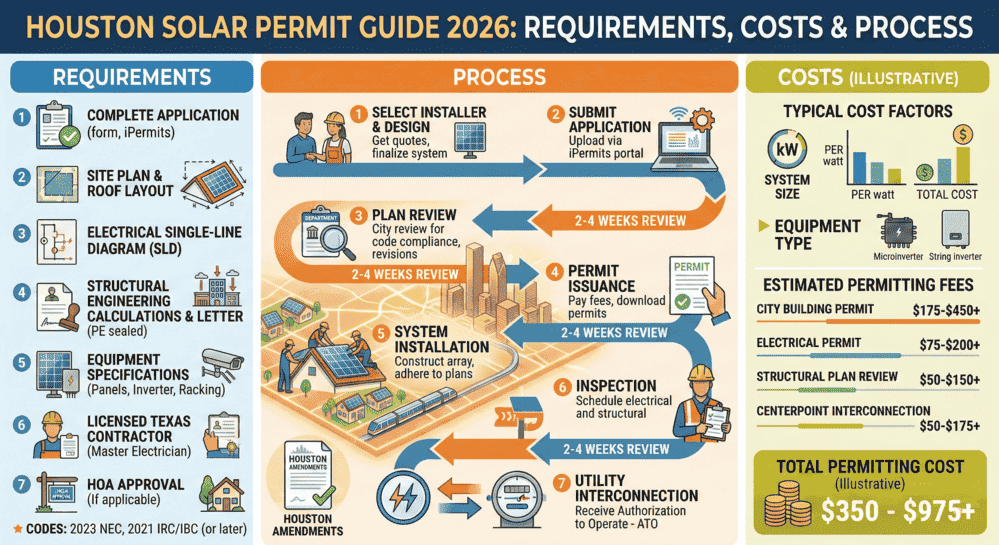

Yes, supply-side connections can be used for residential installations, particularly when the solar system size exceeds what the main panel can accommodate under the 120% rule. Requirements may vary by state, such as Texas solar permits. However, they typically require more coordination with the utility company and may involve higher installation costs due to service entrance modifications.

The PV breaker should be positioned at the opposite end of the busbar from the main breaker to ensure proper current distribution and comply with NEC requirements. Placing the PV breaker at the top of the panel bus near the main breaker can violate the 120% rule and result in inspection failures.

Yes, supply-side interconnections typically require utility coordination and approval since they involve tapping into the service conductors before the main disconnect. Utilities often require sealed metering compartments and specific documentation to ensure the connection meets their standards and safety requirements.

If the main panel cannot accommodate the solar system under the 120% rule, there are several options: downsize the main breaker to create more capacity for solar, install a PV subpanel with its own breaker, or design a supply-side interconnection that bypasses the main panel entirely. The best solution depends on the specific project requirements, budget, and timeline. For complex scenarios, consulting with solar design experts or reviewing state-specific permit guides can help determine the optimal approach.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

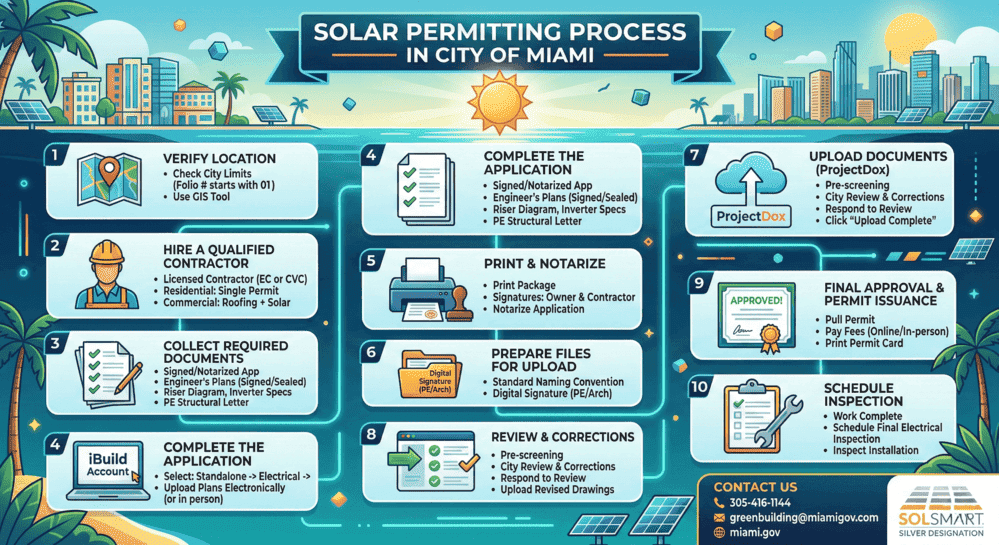

Solar Permit in Miami, FL: City of Miami vs. Miami-Dade County (2026)

Getting a solar permit in Miami requires two separate processes depending on jur...

Houston Solar Permit Guide 2026: Requirements, Costs & Process

Quick Answer: In Houston, TX, solar PV installations require a building permit (...

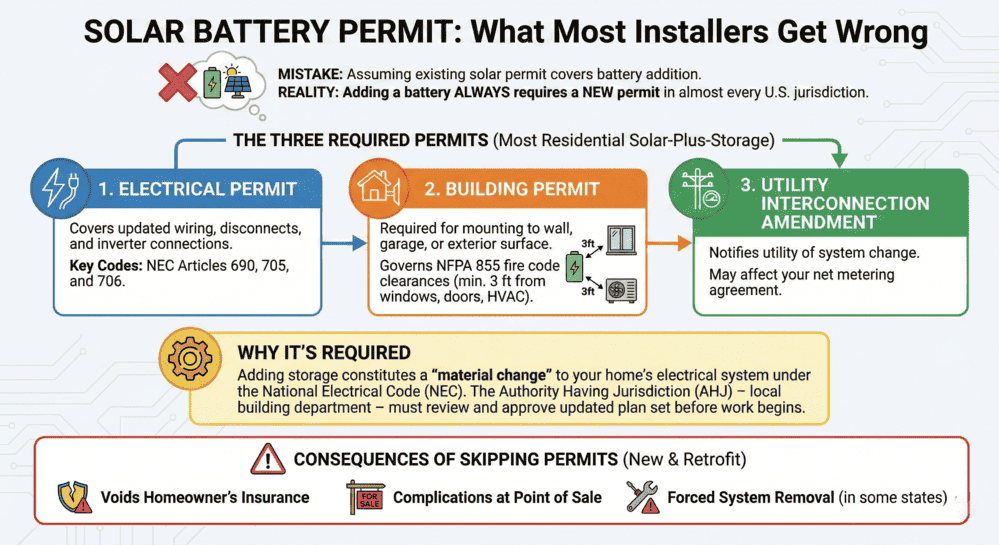

Solar Battery Permit: What Most Installers Get Wrong

Adding a battery to a solar system requires a new permit in almost every U.S. ju...