Optimized solar panel layouts can boost energy output by 15-30% through strategic inter-row spacing, proper tilt angles (latitude plus or minus 15 degrees for seasonal adjustment), and effective shading mitigation. The key factors include orientation (south-facing in the Northern Hemisphere), Ground Coverage Ratio between 0.33-0.45, and string configuration optimization to minimize voltage losses.

How Can Solar Panel Layout Increase Energy Production?

Solar panel layout optimization directly impacts system performance and return on investment. Properly designed installations consistently outperform standard configurations by capturing more sunlight, reducing shading losses, and minimizing electrical inefficiencies.

The three critical elements that determine layout effectiveness are:

Panel Spacing and Orientation Precise inter-row spacing calculations prevent panel-to-panel shading during peak production hours. The spacing depends on panel height, tilt angle, and geographical location. Using the winter solstice sun angle ensures minimal shading throughout the year. Professional residential solar design services incorporate these calculations to maximize system efficiency.

Tilt Angle Optimization Panel tilt angles should match the site’s latitude for year-round performance. Add 15 degrees for winter optimization or subtract 15 degrees for summer gains. Locations between 30 and 40 degrees latitude perform best with tilt angles from 30 to 45 degrees. The Department of Energy provides comprehensive guidelines on PV system design fundamentals.

String Configuration Strategic conductor routing and voltage drop minimization through advanced string topology mapping boost overall panel efficiency. Proper string design accounts for inverter voltage requirements and site-specific shading patterns.

This optimization framework integrates real-world performance data with predictive analytics. System designers achieve peak energy harvest while maintaining long-term operational reliability. Studies show properly optimized solar installations deliver 15-30% higher yields compared to basic configurations, providing superior returns through enhanced efficiency and reduced maintenance needs.

Key Factors Affecting Solar PV Layout Efficiency

Solar Orientation and Tilt Angles

The effectiveness of a solar power system depends heavily on proper orientation and tilt angles. These factors directly impact the amount of solar radiation captured by the panels. During photovoltaic system installation, careful consideration of geographical location is essential.

In the Northern Hemisphere, solar panels should typically face true south (180° azimuth). In the Southern Hemisphere, panels should face true north. Local conditions and specific requirements may necessitate slight deviations from these general guidelines.

Optimal tilt angle varies with latitude and seasonal changes. A common rule sets the tilt angle equal to the site’s latitude for maximum year-round energy production. For winter optimization, add 15° to the latitude angle. For summer optimization, subtract 15°. Locations between 30° and 40° latitude typically achieve optimal performance with tilt angles ranging from 30° to 45°.

Modern mounting systems often incorporate adjustable tilt mechanisms. These allow seasonal adjustments to maximize energy yield. The cost-benefit analysis of adjustable systems versus fixed installations should consider maintenance requirements and local weather conditions. In regions with heavy snowfall, steeper tilt angles (greater than 40°) facilitate natural snow shedding and maintain system efficiency during winter months. Professional design services can help evaluate these system options.

Shading Analysis and Mitigation

Shading presents one of the most significant challenges in solar system performance. Poor shading management can reduce energy yield by up to 25-40%. Even partial shading from nearby structures, trees, or architectural elements can disproportionately impact overall system output. This occurs due to the series connection of solar cells within modules.

Effective shading mitigation requires comprehensive site analysis using advanced solar pathfinder tools and 3D modeling software. These tools simulate shadow patterns throughout the year. System designers can identify optimal panel placement and array configuration. Modern solutions include implementing module-level power electronics (MLPEs), such as power optimizers or microinverters. These significantly reduce the impact of partial shading.

String layout optimization plays a crucial role in shading mitigation. Panels should be arranged to minimize the effect of unavoidable shadows. Consideration must be given to bypass diode activation thresholds. Strategic panel orientation and spacing help reduce inter-row shading, particularly in large-scale installations with multiple array rows.

Advanced techniques include using bifacial modules that capture reflected light. Implementing smart monitoring systems detects shading-related performance issues. Utilizing half-cell technology provides better shade tolerance. Regular maintenance, including vegetation management and periodic cleaning, ensures that temporary shading sources don’t compromise system performance over time. Understanding and addressing shading challenges is fundamental to achieving optimal solar system performance and maximizing return on investment. Research from NREL studies confirms these optimization strategies deliver measurable performance improvements. The UAF Solar Manual provides additional technical guidance.

Advanced Layout Optimization Techniques

Inter-row Spacing Calculations

Inter-row spacing calculations form a critical component of solar array design. These calculations directly impact system performance and energy yield. The optimal distance between panel rows is determined using a mathematical formula. This formula considers three key factors: panel height, sun angle, and geographical location.

The fundamental equation for calculating minimum row spacing is:

D = H × cos(β) / tan(α)

Where:

- D represents the minimum row-to-row distance

- H is the panel height difference (from lower to upper edge)

- β is the panel tilt angle

- α is the minimum solar altitude angle

For most installations, designers typically use the winter solstice sun angle. This represents the worst-case scenario for shading. This conservative approach ensures minimal inter-row shading throughout the year. A general rule suggests maintaining a Ground Coverage Ratio (GCR) between 0.33 and 0.45 for optimal performance.

The calculation should also factor in local conditions:

- Site latitude and longitude

- Local weather patterns

- Ground surface characteristics

- Maintenance access requirements

Professional solar design software often incorporates these calculations automatically. Understanding the underlying mathematics enables designers to verify results and make informed adjustments based on specific project requirements. For maximum system efficiency, designers should balance the desire for dense panel placement against the potential energy losses from inter-row shading. Off-grid system design requires particularly careful spacing analysis due to limited energy storage capacity. The EPA guidelines provide additional context for site-specific considerations.

String Configuration Optimization

String configuration optimization plays a crucial role in maximizing system efficiency and power output in solar installations. The arrangement of photovoltaic modules in series and parallel connections directly impacts voltage levels, current flow, and overall system performance.

When designing string layouts, several key factors must be considered: voltage window requirements of the inverter, maximum power point tracking (MPPT) capabilities, and site-specific shading patterns. The optimal string length is determined by calculating the minimum and maximum number of modules. These modules can be connected in series while maintaining operational voltage limits across varying temperature conditions.

Parallel string configurations require careful matching of electrical characteristics to prevent mismatch losses. Each string should contain modules with similar specifications and exposure conditions. This ensures uniform current production. Implementation of string optimizers or module-level power electronics can help mitigate the effects of partial shading and module mismatch.

Advanced string configuration strategies include:

- Strategic grouping of modules based on orientation and shading patterns

- Balanced distribution of string lengths across multiple MPPT channels

- Implementation of compatible string voltage ranges for selected inverter specifications

- Integration of monitoring systems for string-level performance analysis

Regular assessment of string performance metrics enables identification of potential issues and maintenance requirements. This ensures sustained optimal power harvest throughout the system’s lifecycle. Understanding permit equipment requirements helps ensure compliant installations from the start. Recent research publications demonstrate the impact of proper string configuration on overall system performance.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Modern Software Tools for Layout Design

Modern solar layout design has been revolutionized by sophisticated software tools. These tools combine precision engineering with user-friendly interfaces. Comprehensive solutions integrate multiple aspects of solar system design, from initial site assessment to final optimization calculations.

These platforms utilize advanced 3D modeling capabilities to create accurate representations of installation sites. They account for factors such as roof geometry, shading objects, and local weather patterns. Satellite imagery and LIDAR data generate detailed terrain analysis. Designers can make informed decisions about panel placement and orientation. Studies on array configuration optimization provide valuable insights for software developers. Advanced remote sensing methods further enhance design accuracy.

Key features of these software solutions include automatic stringing optimization. This maximizes system performance while minimizing wiring complexity. Detailed production forecasting accounts for various loss factors. Many tools also offer integrated financial analysis capabilities. Designers can balance technical optimization with economic considerations.

Recent developments have introduced machine learning algorithms. These algorithms suggest optimal layouts based on historical performance data from similar installations. AI-driven recommendations often outperform traditional manual design approaches. Improvements are seen in both energy yield and installation efficiency. Remote sensing technologies enhance site assessment accuracy.

For quality assurance, most professional tools include built-in compliance checking features. These ensure designs meet local building codes and electrical standards. They also generate comprehensive documentation required for permit applications and client presentations. This streamlines the entire project workflow.

Performance Monitoring and Adjustment

Real-time Monitoring Systems

Real-time monitoring systems serve as the foundation for effective solar optimization. These systems provide crucial performance data and insights. System operators can maximize energy yield and identify potential issues before they impact production. Sophisticated systems utilize a network of sensors and data collection devices. These track key performance indicators (KPIs) continuously throughout the day.

Modern monitoring platforms typically measure and analyze several critical parameters. These include DC and AC power output, module temperature, irradiance levels, and inverter efficiency. Advanced systems also incorporate weather station data. This correlates environmental conditions with system performance. More accurate performance ratio calculations and yield forecasting become possible.

Data visualization tools present information through customizable dashboards. Operators can monitor system performance at both macro and micro levels. These interfaces typically display real-time power generation metrics, historical performance data, and automated performance alerts. Many platforms now integrate machine learning algorithms. These detect anomalies and predict potential component failures before they occur.

Key monitoring metrics include:

- Performance ratio (PR)

- Specific yield (kWh/kWp)

- System availability

- String-level current and voltage measurements

- Inverter efficiency rates

- Power quality parameters

Remote monitoring capabilities enable operators to access system data from anywhere. This facilitates quick response times to performance issues. Modern platforms also support automated reporting features. These generate detailed performance analyses and maintenance recommendations based on collected data. Solar Permit Solutions provides comprehensive design services that incorporate monitoring system specifications. Learning how to streamline permit processing ensures faster project completion.

System integration with smart grid infrastructure allows for more sophisticated energy management. Dynamic response to grid demands and optimal energy export timing become possible. This integration becomes particularly valuable in markets with variable electricity pricing or demand response programs.

For larger installations, drone-based thermal imaging and automated visual inspection systems complement traditional monitoring tools. These provide additional layers of performance verification and maintenance planning capabilities. Advanced monitoring solutions help maintain optimal system efficiency while reducing operational costs through predictive maintenance strategies. The NREL technical report outlines best practices for performance monitoring protocols.

Seasonal Adjustments and Maintenance

Maintaining optimal solar system performance requires systematic seasonal adjustments and preventive maintenance strategies throughout the year. As solar irradiance patterns and environmental conditions shift with the seasons, system operators must implement targeted optimization measures. Solar installation safety protocols should be followed during maintenance activities.

During winter months, focus on snow removal protocols and adjusting tilt angles. This maximizes exposure during lower sun angles. Implement automated or manual cleaning schedules to prevent snow accumulation. Verify that heating elements or snow guards are functioning correctly where installed. Panel tilt adjustments typically range between 50-60 degrees in winter months for most northern hemisphere installations.

Spring maintenance should emphasize thorough system cleaning. This removes winter debris and pollen accumulation. Conduct comprehensive inspections of mounting hardware, electrical connections, and inverter performance. This period is ideal for calibrating tracking systems and optimizing tilt angles. Preparation for peak summer production is essential. Understanding permit requirements ensures compliant maintenance procedures.

Summer optimization focuses on temperature management and performance monitoring. Ensure proper ventilation beneath panels. Verify functioning of cooling systems where applicable. Maintain clean surfaces to prevent heat-related efficiency losses. Optimal summer tilt angles typically range between 20-35 degrees, depending on installation latitude.

Fall maintenance prioritizes preparing the system for winter conditions. Clear organic debris. Inspect weather sealing and mounting systems. Verify the functionality of monitoring equipment. Document baseline performance metrics to track seasonal variations and system degradation accurately. State-specific requirements like California solar permits may affect maintenance scheduling.

Year-round maintenance requirements include:

- Monthly performance data analysis

- Quarterly inspection of electrical components

- Bi-annual thorough cleaning

- Annual calibration of monitoring systems

- Regular firmware updates for inverters and control systems

Implementing these seasonal adjustments and maintenance protocols ensures consistent system performance. Predicted energy yields can be achieved across varying environmental conditions. Research on energy optimization techniques supports these maintenance strategies.

Conclusion

Solar optimization represents a critical pathway to maximizing the performance and return on investment of photovoltaic systems. Through strategic implementation of key optimization strategies, system designers and operators can achieve significant improvements in energy yield and system efficiency. Proper integration of module orientation, tilt angle optimization, and shading analysis enables systems to capture maximum solar irradiance throughout the year.

Advanced tracking systems, when economically viable, can enhance energy production by up to 25-40% compared to fixed installations. Smart monitoring systems and predictive maintenance protocols ensure sustained performance optimization while minimizing downtime. String configuration optimization and careful inverter selection maintain high system efficiency under varying environmental conditions.

These optimization approaches typically result in 15-30% increased energy yield, improved system reliability, and enhanced economic returns. As solar technology continues to evolve, staying current with optimization best practices becomes increasingly important for maintaining competitive advantage in the renewable energy sector. Contact our team for professional solar design services.

FAQs

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

The optimal tilt angle depends on the installation's latitude and intended use. For year-round energy production, set the tilt angle equal to the site's latitude. For winter optimization, add 15° to the latitude angle. For summer optimization, subtract 15°. Locations between 30° and 40° latitude typically perform best with tilt angles ranging from 30° to 45°. Adjustable mounting systems allow seasonal changes to maximize energy harvest throughout the year.

Shading can reduce energy yield by 25-40% if not properly addressed. Even partial shading from trees, buildings, or architectural elements disproportionately impacts overall system output due to the series connection of solar cells within modules. Mitigation strategies include comprehensive site analysis using solar pathfinder tools, implementing module-level power electronics like power optimizers or microinverters, and strategic panel placement to minimize shadow effects. Regular vegetation management and system cleaning also help maintain optimal performance.

Ground Coverage Ratio (GCR) refers to the proportion of ground area covered by solar panels compared to the total available area. For optimal performance, designers typically maintain a GCR between 0.33 and 0.45. This ratio balances the desire for dense panel placement against potential energy losses from inter-row shading. Proper GCR calculation considers panel height, tilt angle, solar altitude angle, and site-specific factors like latitude, weather patterns, and maintenance access requirements.

Solar panels require bi-annual thorough cleaning at minimum, with additional cleaning as needed based on local conditions. Monthly performance data analysis helps identify issues early. Quarterly inspections of electrical components ensure system integrity. Annual calibration of monitoring systems maintains accuracy. Seasonal maintenance focuses on specific needs: winter snow removal, spring debris clearing, summer temperature management, and fall preparation for cold weather. Regular firmware updates for inverters and control systems keep the system operating efficiently.

Key monitoring metrics include Performance Ratio (PR), which measures actual output versus expected output under standard conditions. Specific Yield (kWh/kWp) indicates energy production per installed capacity. System Availability tracks operational uptime. String-level current and voltage measurements identify potential issues in specific panel groups. Inverter efficiency rates ensure conversion equipment operates optimally. Power quality parameters verify grid compatibility. Modern monitoring platforms track these metrics in real-time, enabling quick identification of performance issues and maintenance needs.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

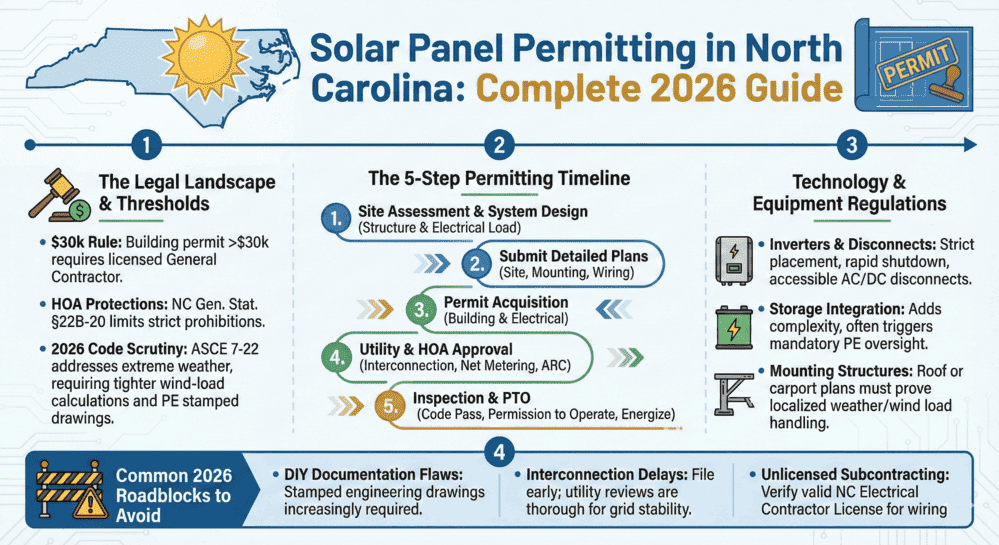

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...