What is a supply-side tap? A supply-side connection (also called line-side tap) integrates solar arrays upstream of the main service disconnect by tapping directly into utility service conductors. Unlike load-side connections restricted by the 120% busbar rule, supply-side taps unlock greater system capacity for projects ranging from 15kW residential installations to large commercial arrays.

In the realm of photovoltaic interconnections, there’s one term that consistently captures every system designer’s attention, “supply-side connection.” This robust approach enables substantial solar installations to interface directly with service conductors before the primary breaker, yet it demands adherence to stringent NEC requirements, AHJ reviews, and power company restrictions.

We’ll examine the fundamentals of supply-side connections, optimal application scenarios, and strategies to prevent typical design and compliance challenges that drain contractor resources and schedules.

1. Understanding Supply-Side Connections

A supply-side interconnection (alternatively termed line-side connection) integrates the photovoltaic array upstream of the primary service disconnect , establishing direct contact with utility service conductors.

This configuration enables the solar installation to circumvent primary breaker restrictions (the 120% guideline per NEC 705.12(D)) and finds application in:

- Substantial residential arrays surpassing panel limitations

- Commercial projects where service infrastructure upgrades prove costly

- Power company connections demanding independent meter installations

2. Critical NEC Code Standards

Expert Recommendation: Verify your AHJ’s current NEC adoption , some jurisdictions continue using 2017 NEC standards, which feature different article numbering and provisions. Understanding solar permit requirements across different states is crucial for compliance.

3. Supply-Side Tap Configuration Options

A. Meter Base Lug Tap Installation occurs at the meter base utilizing approved lugs or split-bolt connections. Enclosure certification must remain intact. Best suited for residential installations rated below 15kW.

B. Service Raceway Tap (Gutter Connection) Conductors connect within a service gutter or trough upstream of the main disconnect. Frequently deployed in commercial and multi-unit residential projects. Compliance with NEC 240.21(B) spacing and length requirements is mandatory.

C. Panel Bus Tap Connection Attachment point occurs at the panel busbar or conductors supplying the main breaker. UL-certified tap kits are required (manufacturers include Milbank, Eaton, and Ilsco). Confirm compatibility with manufacturer specifications and secure AHJ authorization.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

4. Critical Design Guidelines

Execute safe, compliant installations by following these protocols:

Deploy Certified Connectors Exclusively All split bolts and mechanical lugs require UL 486A/B certification. Field-modified or drilled bus bars are prohibited.

Protect Tap Conductors Properly Calculate sizing according to NEC 240.21(B) and install overcurrent protection as near to the tap as feasible. Standard installations limit tap runs to 10 feet maximum.

Execute Proper Grounding and Bonding Equipment grounds and neutrals must remain unbonded beyond the service disconnect point. Install bonding bushings at metallic conduit transition points between enclosures. Proper grounding is essential for solar permit equipment specifications.

Position Disconnects for Easy Access Place PV disconnects in readily accessible locations alongside the utility service disconnect. Apply clear identification: “PV SUPPLY DISCONNECT”.

Apply Compliant Marking NEC 705.10 requires: “Power Source Output Connection – Do Not Relocate This Connection.” NEC 110.21(B) mandates permanent, UV-resistant, reflective labeling.

5. Frequent Inspection Failures

AHJ inspectors regularly cite these violations during line-side tap reviews:

- Uncertified connectors improvised or custom-fabricated connection points

- Missing protective conduit, exposed tap conductors between junction boxes

- Inadequate labeling, absent NEC references or current flow indicators

- Grounding error, neutral bonded at multiple points

- Accessibility problems, disconnects obscured by equipment or barriers

Every violation adds another inspection cycle, delays your timeline by weeks, and risks utility disapproval. Learn more about streamlining your solar permit processing to avoid these setbacks.

6. Coordinating With Your Utility Provider

NEC compliance alone won’t guarantee approval. Utilities may reject installations when:

- Service conductors fall under utility ownership (typical in stacked meter configurations)

- Meter base alterations invalidate utility certifications

- Multiple generation sources (battery systems plus PV) lack proper documentation

Submit these essential documents:

- Utility interconnection schematic

- Photographic tap reference documentation

- Complete equipment specification sheets

- Service configuration drawings identifying tap position and disconnect arrangement

For comprehensive guidance on utility coordination, consult renewable energy resources from UCS and solar permitting best practices. Additional insights are available through the Center for Climate and Energy Solutions.

7. Required Documentation (AHJ + Utility Submittal)

Prepare comprehensive permit packages containing:

- Annotated tap schematic showing all conductor gauges

- As-built tap location photography

- NEC code references accompanying each technical notation

- Grounding schematic illustrating neutral separation and GEC routing

- Complete labeling inventory for all disconnects and junction locations

This thoroughness reassures both AHJ inspectors and utility reviewers of your installation quality. Our detailed guide on solar permit applications steps and requirements provides additional documentation insights. Reference IEEE renewable energy standards and consult the World Bank’s energy resources for technical compliance.

8. Scenarios to Avoid Supply-Side Connections

Exercise caution or select alternative methods when:

- Service conductors use aluminum and present access challenges

- Utility regulations prohibit meter base alterations

- Main service equipment resides in sealed or shared-tenant enclosures

- PV systems rate below 10kW (load-side backfeed offers simpler, more economical solutions)

These situations favor load-side interconnection using the 120% rule for faster, smoother approvals. Before proceeding, consider whether solar permits are necessary for your specific project scope. Understanding what happens if you install solar panels without a permit can help you avoid costly legal complications. Additionally, learn how HOA regulations impact solar permit approval if applicable to your project.

Conclusion

Supply-side connections represent a strategic solution for solar professionals seeking to maximize system capacity without expensive service upgrades. However, success hinges on three critical factors: thorough NEC code knowledge, precise installation execution, and complete documentation.

When implemented correctly, supply-side taps unlock opportunities for larger solar arrays, bypass restrictive panel limitations, and deliver cost-effective alternatives to service infrastructure overhauls. When executed poorly, they trigger inspection rejections, project delays, and financial setbacks that erode profit margins.

The path to approval requires mastering NEC 705.11 provisions, selecting manufacturer-certified components, and maintaining clear communication with both AHJs and utility providers. Your documentation quality directly impacts approval speed , detailed schematics, comprehensive labeling plans, and photographic references transform potentially contentious inspections into straightforward approvals.

As solar installations continue growing in scale and complexity, supply-side connections will remain an essential technique in every designer’s toolkit. Invest time in understanding these requirements now, and you’ll avoid the costly mistakes that plague unprepared contractors.

For state-specific guidance, review our California solar permit guide or Texas solar permit requirements. Whether you’re working on residential projects, commercial installations, or off-grid solar system design, Solar Permit Solutions offers expert design and permitting services to ensure your next project’s success.

For professional assistance with supply-side tap documentation and permit processing, contact our team today. Additional insights and industry updates are available on our solar permitting blog, where we cover everything from complete solar permitting guides to specific compliance challenges.

FAQs

What’s the main advantage of using a supply-side tap instead of a load-side connection?

A supply-side tap bypasses the 120% rule limitation imposed by NEC 705.12(D) on main service panels. This allows you to install larger solar systems without upgrading the main service panel or breaker. It connects directly to the utility service conductors before the main disconnect, eliminating capacity restrictions that would otherwise require expensive panel replacements or service upgrades.

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

A supply-side tap bypasses the 120% rule limitation imposed by NEC 705.12(D) on main service panels. This allows you to install larger solar systems without upgrading the main service panel or breaker. It connects directly to the utility service conductors before the main disconnect, eliminating capacity restrictions that would otherwise require expensive panel replacements or service upgrades.

Evaluate your project using the 120% rule calculation. If your existing main breaker rating plus the solar breaker rating exceeds 120% of the panel's busbar rating, you'll need either a service upgrade or a supply-side tap. Additionally, consider supply-side taps for systems where the utility requires separate metering, or when commercial installations make service upgrades prohibitively expensive. For residential systems under 10kW with adequate panel capacity, load-side connections typically offer simpler, more cost-effective solutions.

The five most frequent violations include: using unlisted or improvised connectors instead of UL 486A/B certified components; failing to protect tap conductors with proper raceways between enclosures; inadequate or missing labeling that doesn't meet NEC 705.10 and 110.21(B) standards; improper grounding with neutrals bonded at multiple locations downstream of the service disconnect; and accessibility issues where disconnects aren't grouped with the main service disconnect or lack clear visibility. Each violation typically adds 1-2 weeks to your project timeline.

Yes, absolutely. AHJ approval confirms NEC code compliance, but utility approval is a separate requirement for interconnection authorization. Utilities may reject installations even after code compliance is verified, particularly when service conductors are utility-owned, meter base modifications void their equipment certifications, or multiple generation sources aren't properly documented. Always coordinate with your utility early in the design phase and submit complete interconnection packages including schematics, equipment specifications, and tap location drawings.

Prepare a comprehensive permit package containing: a detailed tap diagram with all conductor sizes clearly labeled; as-built photographs showing the actual tap point location; NEC code callouts referenced next to every technical specification; a complete grounding diagram illustrating neutral isolation and ground electrode conductor paths; equipment data sheets for all tap components and disconnects; a service layout page showing disconnect grouping and accessibility; and a clear labeling schedule identifying every disconnect and junction point. This thorough documentation demonstrates professional competence and significantly accelerates the approval process with both authorities.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

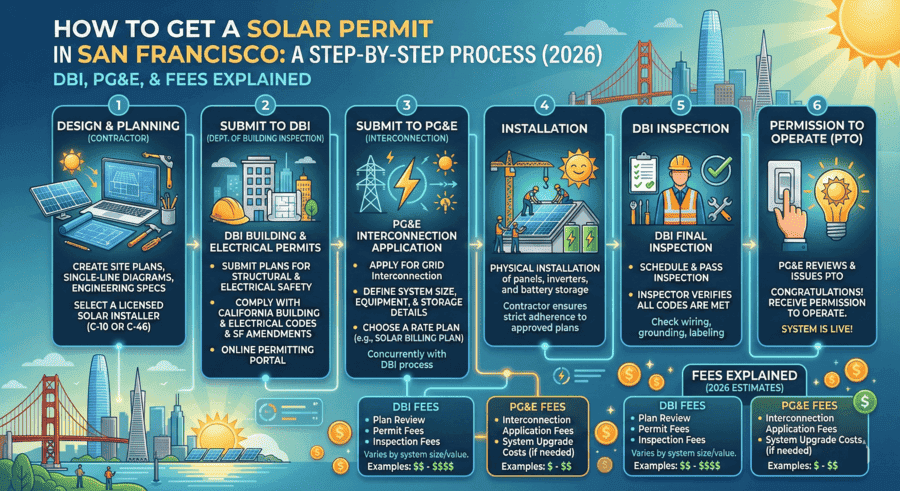

How To Get A Solar Permit In San Francisco: DBI, PG&E And Fees Explained (2026)

San Francisco solar permits require two separate approvals before your system ca...

Bifacial Solar Panel Installation And Permitting Guide

Bifacial solar panels generate 10 to 30 percent more energy than traditional mon...

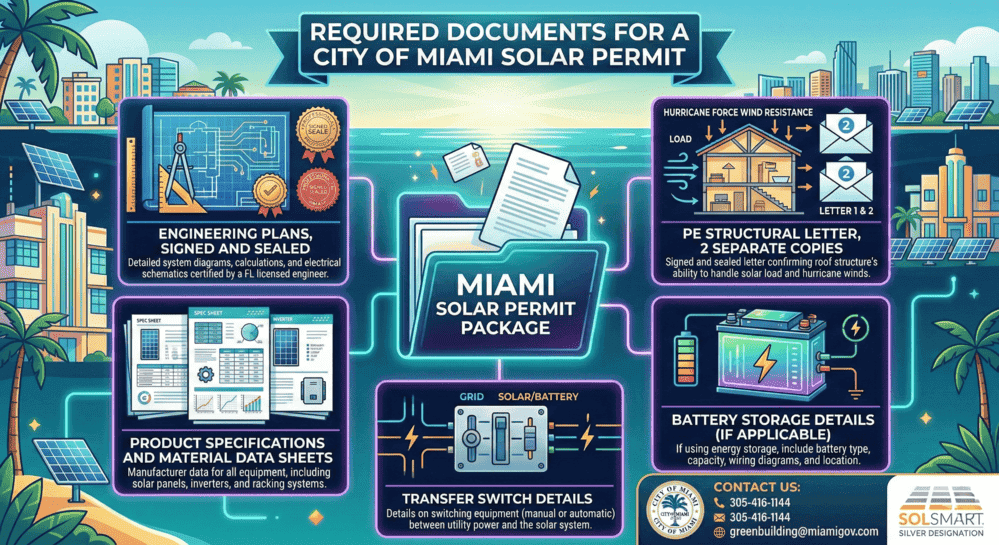

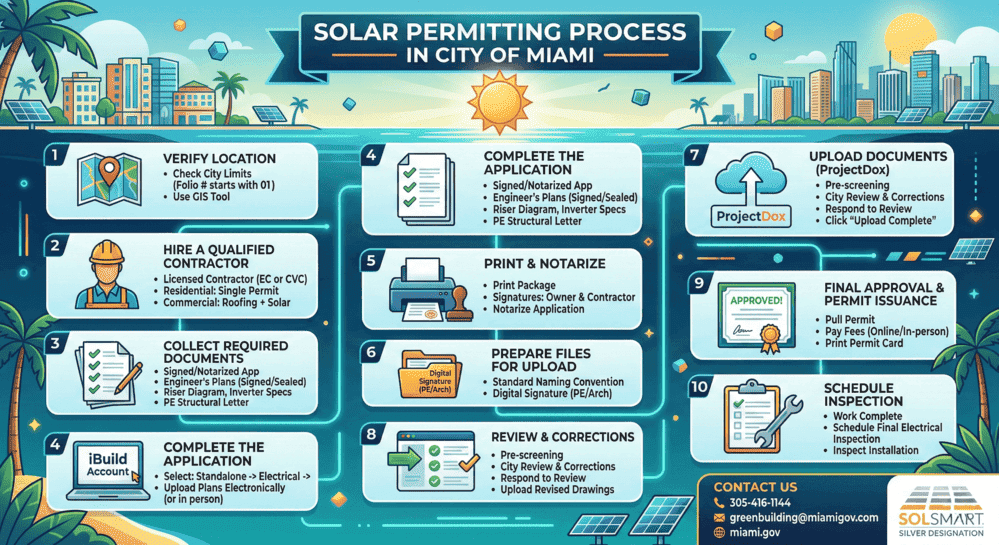

Solar Permit in Miami, FL: City of Miami vs. Miami-Dade County (2026)

Getting a solar permit in Miami requires two separate processes depending on jur...