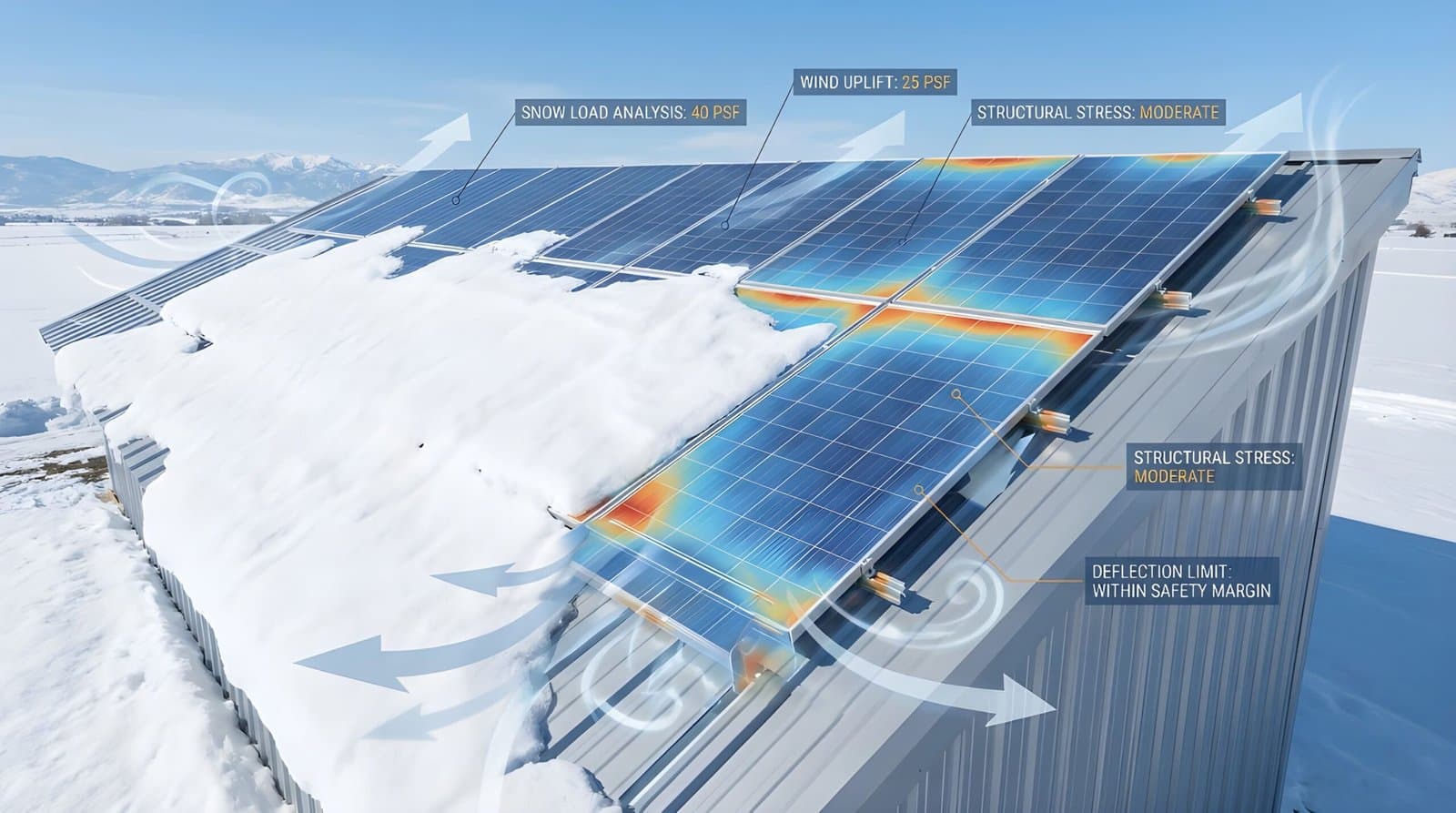

Solar wind load and snow load analysis evaluates the forces acting on solar panel mounting systems to ensure they survive extreme weather. Wind loads measure uplift, shear, and overturning forces (typically 90-150 mph ratings), while snow loads account for weight accumulation (30-90 psf depending on region). Proper analysis prevents system failure during hurricanes, storms, and heavy snowfall by following ASCE 7 standards and local building codes.

Wind zones can see gusts up to 120 mph, and northern regions may face snow loads of 70 psf or more, making proper load analysis essential for system survival. A one-size-fits-all design simply won’t work for these extreme conditions.

What This Guide Covers: This comprehensive guide walks through how to plan, test, and build solar mounting systems for high wind areas and deep snow. Readers will learn key terms, wind uplift calculations, snow drift considerations, structural load factors, and a step-by-step plan to choose the right solar racking systems for extreme weather conditions.

Why Wind And Snow Loads Matter

Wind and snow can break a system that is not built right. High winds can lift panels from roofs or tilt mounts out of place. Snow can pile up and add weight far above the roof’s limit. For solar permits in the USA, many local codes require proof that systems can stand these loads.

Wind uplift solar mounting forces often rise fast in hurricanes or storms. A standard flat roof may face 90–120 mph wind gusts in places like New Jersey or Florida. Likewise, snow loads can reach 70 psf in northern states. These numbers must guide the system choice, particularly for residential solar design projects.

What Is Wind Load In Solar Mounting?

Wind load means the push or pull of wind on the panels and frame. It can cause:

- Uplift (pulling panels off)

- Shear (pushing sideways)

- Overturning (tilting mounts)

Solar panel wind resistance is measured in pounds per square foot (psf) or wind speed ratings like 120 mph. Engineers use ASCE 7 rules to work out these forces.

When picking high wind solar mounting systems, clear wind zone solar installation ratings are essential. For instance, a system rated for 120 mph wind is made for hurricane-prone zones.

Wind Uplift And Structural Loads

Wind uplift is key for flat roofs. A poor design can see mounts ripped free in storms. Wind creates suction on panels. The mount must hold tight.

Structural load solar mounting plans check not just the weight of the panels but also forces from wind. Brackets, bolts, and rails need the right size and strength. Commercial solar installations demand especially rigorous structural analysis due to larger arrays and higher wind exposure.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

What Is Snow Load In Solar Racking?

Snow load is the weight of snow on a system. It varies by region. For example:

- Upstate NY: 40–60 psf

- Midwest: 30–50 psf

- Northern Rockies: 60–90 psf

Engineers use snow load calculations to see how much weight the mounts must hold.

Snow drift solar panels are another risk. Snow can pile unevenly due to the wind. That drift must be in the plan.

Snow Load Testing

Snow load testing solar panels means checking:

- Frame strength

- Mount connections

- Tilt angles (to shed snow)

A good design avoids sagging or breakage in deep snow. Snow load requirements for solar racking often come from local building codes. Research shows that photovoltaic performance decreases significantly when snow accumulates on panels.

How To Calculate Wind Load For Solar Mounting Systems

Step-By-Step Guide

Step 1: Know Your Wind Zone

Check local maps or solar permit guides. For wind zone solar installation in places like Florida, wind speeds may reach 150 mph. Understanding permit requirements nationwide helps ensure compliance across different regions.

Step 2: Find The Exposure Category

This tells how open the site is. Open fields get more wind. Dense city blocks have less.

Step 3: Use The Building Code

Codes like ASCE 7 offer ways to compute forces. Height, shape, and wind speed are needed. Grid-scale installations require additional considerations for environmental exposure.

Step 4: Apply Load Factors

These factors raise the base wind load to be safe for rare high winds.

Step 5: Add Uplift Calculations

Wind uplift solar mounting checks if the system resists suction from wind.

Complete guide tip: Always get local rules. Solar permit rules change by state.

Snow Load Requirements For Solar Racking

How to check snow loads:

- Get local snow load (e.g., 70 psf)

- Add drift if needed

- Apply a safety factor

- Choose mounts with tested load ratings

Selecting systems designed for strong roofs with high snow loads is crucial. It is essential to pick the right tilt and rail size. Standardized load tables provide region-specific guidance for structural requirements.

Engineering For Extreme Weather

Solar mounting system engineering is more than picking strong parts. It involves:

- Load paths (how forces move to the roof)

- Bracket spacing

- Bolt strength

- Roof type (wood, metal, concrete)

Hurricane-resistant solar mounting designs need extra testing. They use more or bigger brackets, thicker rails, and better connections. Working with experienced solar design services ensures proper engineering from the start.

Wind-Resistant Solar Panel Mounting Solutions

Wind-resistant solar panel mounting solutions include:

- Stronger materials (aluminum, stainless steel)

- Rail-free options to cut uplift

- More bracket points

- Tested design

Systems that reduce uplift zones and cut gaps where wind can catch are ideal for areas with high winds. Studies on winter weather resilience show proper mounting reduces failure rates significantly.

Snow Load Solar Racking Best Practices

Snow load solar racking needs:

- Steep tilt (to shed snow)

- Heavy-duty rails

- Strong connections to the roof

- Certified load ratings

Use the local code as a base. Always plan for worst-case drift. Off-grid systems in remote areas face unique challenges with limited maintenance access during severe weather.

Solar Racking Systems For Extreme Weather Conditions

Solar racking systems for extreme weather conditions must be:

- Tested for wind and snow

- Certified to meet code

- Installed by trained crews

In places like New Jersey, wind codes often demand 120 mph ratings. Snow loads can hit 50–70 psf. Choose systems that pass these tests. Avoiding common permit mistakes prevents costly redesigns and delays.

Weather-Resistant Solar Racking Materials

Materials matter. Pick:

- Anodized aluminum for corrosion

- Stainless bolts and brackets

- UV-resistant plastics

These stand up to rain, snow, ice, and sun for years. Weather-resistant design avoids rust and weak spots. Research on solar mounting design emphasizes material selection for long-term durability.

Structural Load Solar Mounting And Roof Types

Roof type changes the entire approach to solar mounting design. For example, wood roofs often require brackets that are spread out carefully to distribute the load without over-stressing any one area. Concrete roofs can handle higher structural loads overall, but they typically need specialized bolts or bracket systems to ensure a secure hold.

Metal roofs, on the other hand, may use clamping systems instead of screws to avoid penetrations while still providing strong connections. Every roof has its own limits and characteristics, so solar mounting system engineering must start with a careful review of roof specifications before finalizing the design. By matching the mounting plan to the roof type, installers can ensure a safe, code-compliant, and long-lasting solar installation that resists wind and snow forces.

Understanding California permit requirements is especially important given the state’s unique seismic and wind considerations.

Testing And Standards

Good solar mounting systems are not chosen by guesswork; they are tested and certified to meet industry standards. Systems must be evaluated under ASCE 7 guidelines for wind loads to ensure they can resist uplift and shear forces expected in their region. They also need to meet local snow load requirements, which can vary dramatically between states and even towns.

Certified laboratory testing confirms that mounts, rails, and fasteners can handle these demands without failure. Wind uplift and snow load testing of solar panels are essential steps in ensuring safety and reliability. When choosing a system, it is critical to look for these certified ratings to avoid failures in extreme weather conditions. Documentation on mounting system specifications provides technical benchmarks for comparison.

Solar Permits And Local Rules

Solar permits in the USA can differ widely depending on the state or municipality. For example, in New Jersey, local permitting often requires a detailed wind load report confirming that the design can handle conditions up to 120 mph. Snow load proof is also typically required, with values around 50 to 70 psf depending on the county.

In many places, the plans must also carry an engineer’s seal to show that they meet structural safety standards. Navigating these rules can be complex, which is why working with local experts who know the codes is so important. Proper permitting not only ensures safety but also prevents delays and legal issues that could halt projects. Learn more about what happens without permits to understand the risks.

Installation Tips

Installers should:

- Use correct brackets and spacing

- Check the torque on bolts

- Seal roof penetrations

- Follow the manufacturer’s installation guide

Even the best mounts fail if installed wrong. Streamlined permit processing helps ensure installations meet all technical requirements from the start.

Common Mistakes To Avoid

- Ignoring local wind/snow data

- Using mounts with low ratings

- Poor bracket spacing

- Wrong tilt angle (for snow shedding)

- Skipping structural review

Choosing The Right System

Choosing the right solar mounting system means taking several careful steps. Start by finding out the local wind and snow load requirements for the area. Check roof type and age to understand its limits and needs. Always pick a system with certified ratings that prove it can handle the expected loads. Plan the bracket layout to match the roof structure and load paths. Make sure to get all required permits before starting work. During installation, follow the manufacturer’s specifications exactly, and finish with a thorough inspection and test to confirm everything is secure and safe.

Having proper permit equipment documentation ensures all components meet local code requirements. Studies on rooftop system performance and cold climate installations provide valuable insights for system selection.

Conclusion

Solar wind load and snow load analysis is not optional for installations in extreme weather regions. Systems that ignore these critical factors face catastrophic failure when storms hit or heavy snow accumulates. The difference between a system that survives 120 mph winds and one that gets ripped from the roof comes down to proper engineering, certified materials, and careful installation.

Every region has unique challenges. Coastal areas battle hurricane-force winds and salt corrosion. Northern climates deal with deep snow and ice accumulation. Understanding local building codes, ASCE 7 standards, and regional weather patterns forms the foundation of safe solar design.

The investment in proper wind and snow load analysis pays off through decades of reliable performance. Systems built to code protect property, generate consistent energy, and avoid costly repairs or legal issues. Working with experienced engineers and certified installers ensures that solar mounting systems can truly survive extreme weather conditions.

For professional assistance with solar design and permitting, contact us or explore our blog resources.

FAQs

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Solar panels should withstand wind speeds based on local building codes and ASCE 7 standards. Most residential systems are designed for 90-120 mph winds, while hurricane-prone areas like Florida may require ratings up to 150 mph. Commercial installations in high-risk zones often need even higher ratings. Always check local wind zone maps and permit requirements to determine the minimum acceptable wind speed rating for the specific location.

Solar panel snow load capacity varies by system design and local requirements. Standard residential systems typically handle 30-50 psf, while northern regions may require 60-90 psf ratings or higher. The mounting structure, not just the panels themselves, determines total snow load capacity. Engineers must also account for uneven snow drift, which can create localized heavy loads. Always verify that the complete system (panels, rails, brackets, and roof structure) meets or exceeds local snow load codes.

Most jurisdictions require a structural engineer's seal on solar permit applications, especially for systems in high wind or snow load areas. Engineers verify that the roof can support the additional weight and forces from the solar array. They calculate load paths, specify proper bracket spacing, and ensure code compliance. Even if not legally required, having an engineer review the design prevents costly failures and provides liability protection. The upfront engineering cost is minimal compared to potential damage from inadequate design.

Wind load is the general term for all forces wind exerts on a structure, including uplift, shear, and overturning forces. Wind uplift specifically refers to the suction force that pulls panels and mounting systems away from the roof surface. This happens because wind flowing over a roof creates negative pressure on the leeward side. Uplift is often the most dangerous force for flat-roof solar installations because it can literally rip mounting systems free during storms. Proper wind load analysis must address all three force types.

Roof type dramatically impacts mounting strategy for extreme weather. Wood roofs require careful bracket spacing to avoid overstressing individual points and may need reinforcement for high loads. Concrete roofs handle higher loads but need specialized anchors and weatherproofing. Metal roofs often use non-penetrating clamps to maintain weather integrity while resisting wind forces. Flat roofs face higher wind uplift than sloped roofs and may require ballasted systems. Each roof material has different load-bearing characteristics, fastener requirements, and weather vulnerabilities that must be addressed in the mounting design.

Solar panels can survive hurricanes when properly designed and installed for extreme wind conditions. Systems in hurricane zones must be rated for sustained winds of 120-150 mph plus higher gusts. This requires additional brackets, reinforced rails, engineered load paths, and often special hurricane-rated hardware. Proper installation is equally critical as many hurricane failures result from incorrect bracket spacing or inadequate fastening rather than equipment failure. Systems that meet building code standards for High Velocity Hurricane Zones provide the best protection, though no system is completely immune to catastrophic direct hits from major hurricanes.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

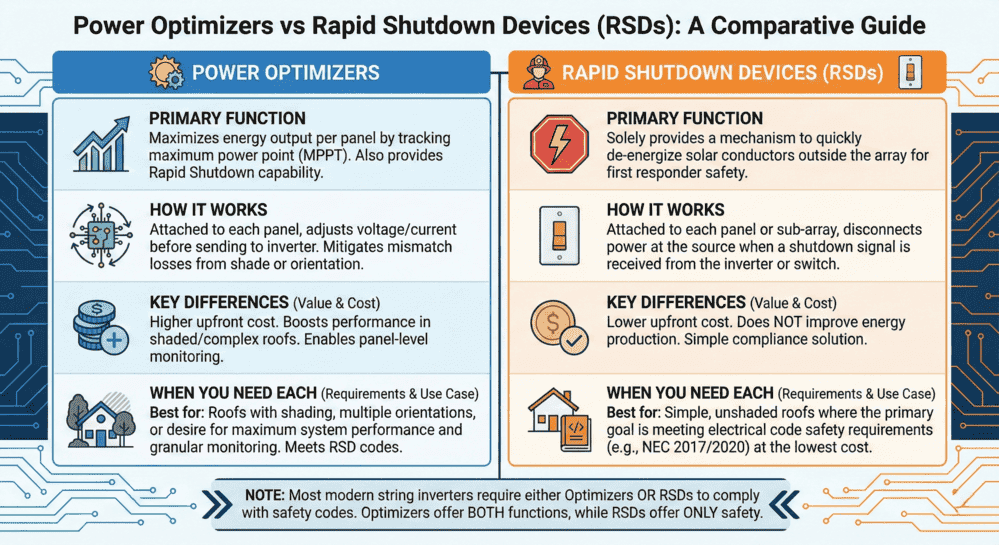

Power Optimizers vs Rapid Shutdown Devices: Differences, Requirements & When You Need Each

When planning a solar installation, understanding the difference between rapid s...

Your Complete DIY Solar Panel Installation Guide

Homeowners turn to solar energy for various motivations. Clean, renewable power ...

What Is A Commercial Solar PV System?

A commercial solar PV system is a renewable energy setup designed to help busine...