Proper wire management and conduit installation are critical for passing solar inspections and meeting NEC compliance. Best practices include using PVC Schedule 40/80 for outdoor runs and EMT for commercial applications, maintaining support spacing of 3 to 4 feet on horizontal runs and 6 to 8 feet on vertical runs, and keeping DC and AC circuits separated. According to NEC 300.11, 690.31, and 690.31(E), solar conductors must be properly supported, protected, and clearly labeled. Common mistakes like incorrect conduit fill calculations, improper bend radius, and mixing AC/DC conductors can trigger inspection corrections and permit delays.

This guide covers essential wire management and conduit installation practices that help contractors save time, reduce rework, and pass inspections on the first try.

The Importance Of Proper Wire Management

Proper wire management isn’t just about aesthetics. It impacts:

- Safety: Prevents chafing, overheating, and accidental damage.

- Compliance: NEC requires secure, supported, and protected conductors.

- Inspection Success: Neatly routed, labeled, and secured wiring reduces corrections.

- Efficiency: Easier maintenance and troubleshooting later.

Key Conduit Installation Best Practices For Solar Projects

1. Use The Right Conduit Type:

- PVC Schedule 40/80 for outdoor runs.

- EMT for exposed or commercial runs.

- Flexible metallic conduit (FMC) only where movement is required.

2. Support Conductors Properly:

- NEC 300.11 & 690.31(C) specify maximum spacing.

- Use appropriate clamps, hangers, and supports for both AC and DC wiring.

3. Avoid Sharp Bends:

- Maintain minimum bend radius per manufacturer specs.

- Sharp bends stress wires and can create hotspots.

4. Keep DC And AC Separate:

- Avoid running DC and AC conductors in the same conduit to reduce interference.

5. Label Every Conduit:

- Clearly mark AC, DC, rapid shutdown, and grounding conduits.

- Use weatherproof labels for outdoor runs.

6. Plan For Future Expansion:

- Don’t cram all wires in a single conduit. Leave extra space for potential system upgrades.

Frequent Installation Errors To Avoid

- Running multiple DC circuits in one conduit without fill calculation.

- Using incorrect bend radius or forcing conductors around tight corners.

- Not securing wires to the roof or racking, leaving them loose.

- Forgetting to separate AC and DC circuits, creating inspection flags.

- Skipping conduit bonding or grounding when required.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Critical NEC Code References For Solar Installers

- NEC 300.4 & 300.11: Protection from physical damage and proper support.

- NEC 690.31: Wiring methods specific to PV systems.

- NEC 690.31(E): DC conductors in raceways require listing and marking.

- NEC 250.64 & 250.118: Grounding and bonding of metallic conduit.

Following these sections ensures wiring and conduit installations pass inspections and meet code requirements.

Practical Field Installation Tips

- Pre-cut conduit runs and plan wire pulls before installation.

- Use conduit supports every 3 to 4 feet on horizontal runs and every 6 to 8 feet on vertical runs.

- Document conduit paths in plan sets for AHJ review.

- Use color-coded wires (red/black for DC, white/green for AC) for clarity.

- Verify grounding/bonding connections at each conduit transition.

Benefits Of Professional Solar Plan Sets

Professional solar plan sets and permit designs include:

- NEC-compliant conduit layouts.

- Proper wire fill calculations and bend-radius verification.

- Clear labeling and diagrams that minimize AHJ corrections.

- Tips for field installers to ensure inspection-ready wire management.

With quality designs, contractors save time, reduce redlines, and improve customer satisfaction.

Keep Installs Clean, Compliant, And Fast

Don’t let messy wiring delay approvals. Professional solar project designs with AHJ-approved conduit and wire management plans streamline the permitting process and ensure successful inspections.

Conclusion

Proper wire management and conduit installation are fundamental components of successful solar projects. Clean, organized wiring not only ensures compliance with NEC requirements but also demonstrates professionalism that inspectors and AHJs appreciate. By following best practices for conduit selection, wire routing, labeling, and support spacing, contractors can significantly reduce permit delays and avoid costly corrections.

The key to inspection-ready installations lies in attention to detail. Taking the time to plan conduit paths, calculate wire fill properly, maintain appropriate bend radii, and separate AC from DC circuits will pay dividends throughout the project lifecycle. These practices improve safety, simplify maintenance, and enhance system reliability for years to come.

Investing in quality wire management from the start saves time and money in the long run. With proper planning and adherence to NEC standards, solar installations can pass inspections on the first try, leading to faster project completion and satisfied customers.

FAQs

Have questions about your solar project? Contact Solar Permit Solutions for expert guidance on permit-ready designs that meet all NEC standards and local requirements. Learn more about what happens when permits aren’t obtained or how to navigate HOA regulations.

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

According to NEC guidelines, horizontal conduit runs typically require supports every 3 to 4 feet, while vertical runs need supports every 6 to 8 feet. However, specific requirements may vary based on conduit type, size, and local code amendments. Always consult NEC 300.11 and 690.31(C) for exact specifications applicable to the installation.

No, it is not recommended to run DC and AC conductors in the same conduit. Keeping these circuits separate reduces electromagnetic interference and makes troubleshooting easier. Additionally, many jurisdictions flag mixed AC/DC conduits during inspections as potential code violations. Always maintain separate pathways for DC and AC wiring.

Conduit fill is calculated based on the total cross-sectional area of all conductors compared to the interior area of the conduit. NEC Chapter 9, Table 1 specifies that conduits can be filled to 40% capacity for three or more conductors. Use NEC Chapter 9 tables along with conductor specifications to ensure proper fill ratios and avoid overloading conduits.

PVC Schedule 40 or Schedule 80 is commonly used for outdoor and underground runs due to its weather resistance and durability. EMT (Electrical Metallic Tubing) is preferred for exposed commercial installations where additional physical protection is needed. The choice depends on environmental conditions, local code requirements, and whether the conduit will be exposed to physical impact or UV exposure.

Proper labeling is critical for safety, compliance, and future maintenance. Labels help identify which conduits carry AC power, DC power, rapid shutdown circuits, or grounding conductors. Clear labeling prevents accidental contact with energized circuits during maintenance and helps inspectors quickly verify code compliance. Use weatherproof labels that can withstand outdoor conditions for long-term durability.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

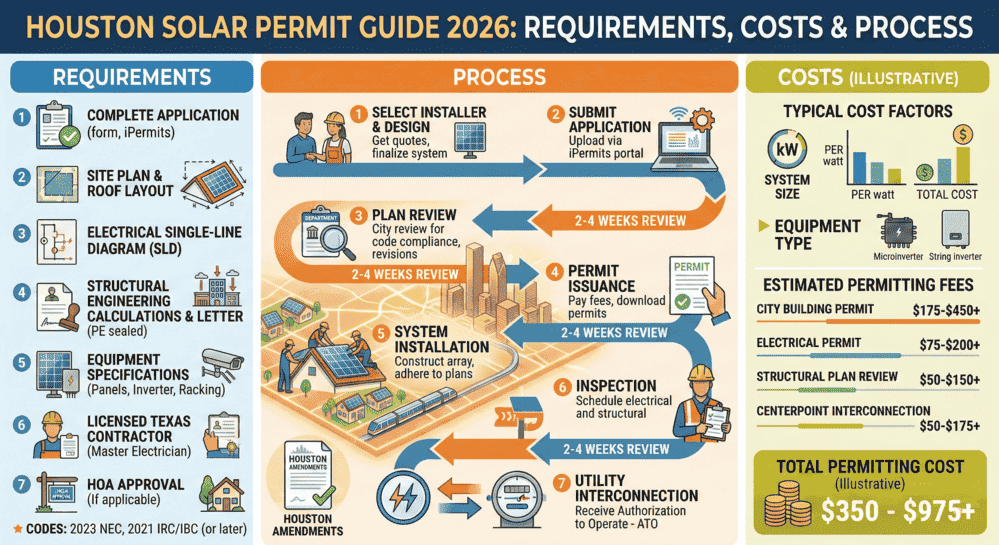

Houston Solar Permit Guide 2026: Requirements, Costs & Process

Quick Answer: In Houston, TX, solar PV installations require a building permit (...

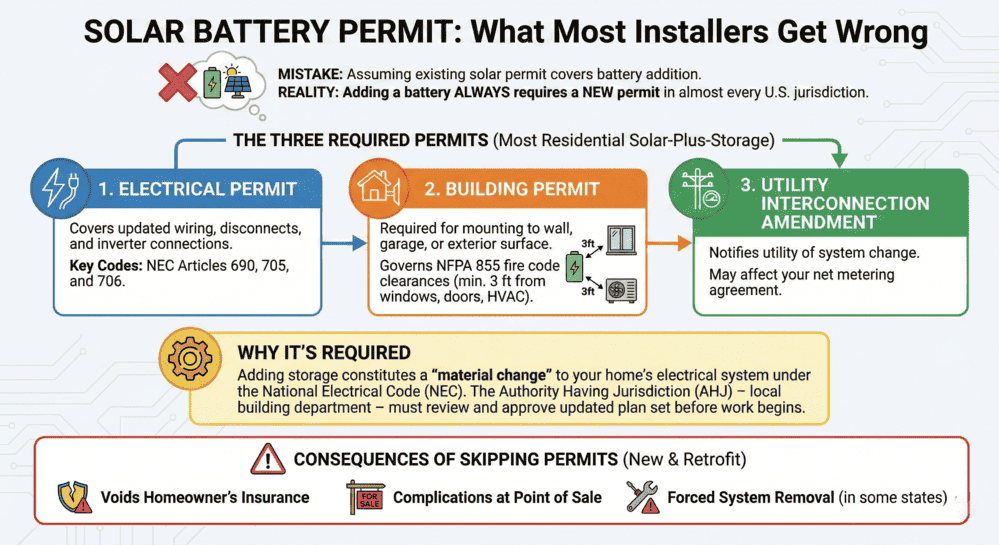

Solar Battery Permit: What Most Installers Get Wrong

Adding a battery to a solar system requires a new permit in almost every U.S. ju...

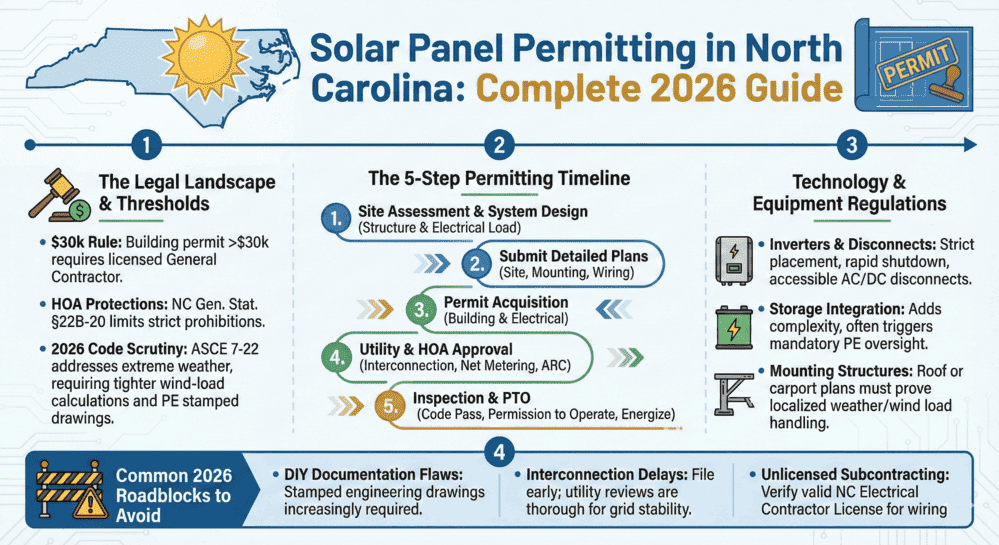

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...