As-built drawings are technical documents that show the final, actual construction of a solar installation, capturing exact dimensions, locations, and specifications of all structural and electrical components as they were built on-site. Unlike original design plans, as-built drawings reflect real-world conditions and are essential for compliance verification, maintenance, troubleshooting, and future system upgrades.

Why As-Built Drawings Matter in Solar Projects

As-built drawings serve four critical functions in solar engineering:

Design Verification – They confirm whether the final installation matches original specifications and identify any necessary modifications

Regulatory Compliance – They prove to inspectors that all components meet building codes and safety standards

Construction Management – They help contractors and project managers maintain accuracy during installation

Long-Term Operations – They enable faster repairs, reduce downtime, and simplify future upgrades by eliminating guesswork

Who creates them? As-built documentation is a collaborative responsibility shared by architects, engineers, general contractors, and subcontractors throughout the construction process.

When are they needed? As-built drawings should be updated continuously during construction and remain accessible for the entire 20-30+ year lifespan of the solar system.

The Role of As-Built Documentation in Solar Engineering

When it comes to solar engineering, accuracy and efficiency work together seamlessly. As-built documentation goes far beyond administrative requirements, it serves as an essential component of project execution. These technical drawings capture the system’s actual construction, providing structural and electrical professionals with a reliable, accurate reference point. From diagnostic work to system expansions or simple verification checks, this documentation reveals the true on-site conditions, beyond initial design specifications.

What makes as-built documentation vital in solar structural work? The answer is straightforward, it anchors everything in actual conditions. The drawings reflect completed construction (rather than preliminary plans), enable teams to maintain coordination when site conditions evolve, and prevent unexpected complications during inspections or future service work. Facing a diagnostic challenge down the road? This documentation provides the solution. Planning system enhancements years later? You’ll appreciate having this reference. This concise overview covers the essentials, because sustainable solar projects begin with accurate construction documentation.

Accountability for As-Built Documentation

Creating as-built documentation isn’t a single-person responsibility. Design professionals, technical specialists, general contractors, and trade contractors, everyone plays a role. During construction, conditions evolve. Specifications adjust. The entire team must ensure these modifications are captured in the documentation. This requires consistent communication, information sharing, and systematic organization. With proper team coordination, significant issues are prevented, eliminating unexpected problems, expensive corrections, and last-minute complications during system operation or expansion. Collaborative effort maintains project integrity, both immediately and for the system’s operational lifetime.

Understanding As-Built Documentation in Solar Work

What does this documentation actually include? As-built drawings document the completed, physical state of construction. They record precise dimensions, locations, and specifications for every structural and electrical element after installation completion. With solar installations, precision is critical. Panel spacing measurements. Mounting system anchor points. The precise routing of electrical conductors between connections is documented. As-built drawings capture it all, the complete PV system configuration, with comprehensive accuracy. When maintenance, upgrades, or expansions are needed, you avoid speculation or investigation. The information is readily available.

Confirming Design Compliance

A primary function of as-built documentation is comparing final construction against initial specifications. Essentially, preliminary designs establish the blueprint. As-built documentation reveals actual construction results. Structural professionals can use as-built records to spot deviations from specifications and assess whether corrections or adjustments are warranted. Understanding residential solar design or commercial solar design requirements helps ensure these comparisons are meaningful and comprehensive.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Enabling Construction Management

During active construction, as-built documentation keeps everything aligned. General contractors and site supervisors consult as-built records to guide panel, mounting, and conduit installation. By reviewing documentation throughout construction, teams catch issues promptly, prevent costly rework, and maintain project timelines. This is particularly important when working with solar panel racking systems, where proper structural load design is crucial for system safety and performance.

Ensuring Regulatory Compliance

Building regulations and safety requirements are absolute: compliance is binary. As-built documentation provides your verification. It demonstrates that every fastener, support component, and conductor was installed according to standards, and the complete system adheres to code requirements throughout. It proves to inspectors and regulatory authorities that structural integrity is sound, electrical installation is safe, and the entire configuration meets applicable requirements. When documentation is thorough and precise? Approval processes typically proceed much more smoothly. No uncertainty, no emergency corrections, no unexpected penalties. Simply one fewer concern as construction concludes.

Meeting AHJ solar requirements becomes significantly easier when as-built drawings accurately reflect the installation. Many installers learn about common mistakes when applying for solar permits the hard way, incomplete or inaccurate as-built documentation being a frequent culprit. Resources like the Solar PV construction codes and permitting guidance from SolSmart provide valuable frameworks for ensuring compliance.

Enabling Future Service Operations

Installation completion doesn’t diminish the value of as-built documentation, often, that’s precisely when it becomes the most critical resource available. Solar installations are engineered for multi-decade operation, but systems evolve. Conductors require replacement. Panels need upgrading. Advanced technology gets integrated. When these changes occur, service personnel must understand the existing configuration.

Precise as-built records eliminate uncertainty. They reveal exact locations of conduit runs, junction points, and components, including critical details about solar interconnection configurations. This means fewer complications, quicker repairs, and reduced downtime. In an industry where every downtime hour represents lost generation and revenue, this precision is invaluable. The documentation continues delivering benefits well beyond project completion. Whether working on off-grid solar system design modifications or grid-tied upgrades, having accurate as-built drawings is essential.

Enhancing Safety and Risk Control

Safety remains the top priority, especially with construction and electrical installations. Technical drawings support hazard evaluation and confirm safe system design. They verify whether structural components can withstand environmental loads and whether electrical systems have proper grounding and protection before energization. When safety concerns are identified promptly, personnel and assets remain protected. This is especially critical for DIY solar panel installation projects, where professional-grade documentation helps ensure safety even when working independently.

The Solar Energy Technologies Office at the Department of Energy emphasizes the importance of proper documentation in reducing installation risks and improving system longevity. Industry organizations like IEEE Power & Energy Society’s Renewable Energy Technical Committee also provide technical standards that rely on accurate as-built documentation for verification purposes.

Conclusion

To sum up, as-built documentation is fundamental to successful solar project completion. It validates design implementation and guides construction teams; it confirms regulatory compliance and supports future service operations. Whether you need solar permit expediting services or are navigating California solar permit requirements, understanding if solar permits are necessary starts with recognizing the role of comprehensive documentation.

By investing effort in developing thorough and precise as-built documentation, and ensuring accessibility, solar professionals can enhance project results, minimize risks, and contribute to advancing renewable energy adoption. For more insights and resources, explore our blog or contact our team for professional assistance with your solar project documentation needs.

FAQs

What happens if as-built drawings aren’t accurate or are missing?

Without accurate as-built documentation, solar projects face significant risks and challenges. Maintenance teams must waste time investigating system layouts, repairs take longer and cost more, safety hazards may go undetected, regulatory compliance becomes difficult to prove, and future upgrades or expansions require extensive site surveys. Inaccurate or missing as-builts can lead to costly errors, project delays, failed inspections, and increased liability, making them a critical investment in any solar installation’s success. Understanding solar radiation patterns and site-specific conditions becomes much more difficult without proper documentation.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

As-built drawings are technical documents that capture the final, actual state of a solar installation as it was constructed. Unlike design drawings that show what was planned, as-built drawings reflect the real-world placement, dimensions, and specifications of all structural and electrical components—including panel spacing, racking anchor points, conduit routes, and connection locations. They serve as the definitive record of how the system was actually built on-site.

Creating as-built documentation is a collaborative effort involving the entire project team. Architects, engineers, general contractors, and subcontractors all share responsibility for ensuring the drawings accurately reflect construction progress and changes. Throughout the build, as site conditions shift and specifications adjust, each team member must communicate updates and modifications so they can be documented. This coordinated approach ensures the final as-built drawings are comprehensive and accurate.

As-built drawings serve as proof that your solar installation meets all building codes and safety standards. They demonstrate to inspectors and permitting authorities that every component—from fasteners and brackets to wiring and grounding systems—was installed according to code requirements. When as-built documentation is thorough and accurate, the approval process typically moves faster, with fewer corrections needed and reduced risk of violations or penalties.

As-built drawings become increasingly valuable over a solar system's multi-decade lifespan. When maintenance is needed or upgrades are planned, service teams can reference the drawings to understand exactly what they're working with—including the precise locations of conduits, connections, and components. This eliminates guesswork, speeds up repairs, reduces downtime, and makes future expansions or technology integrations much more efficient and cost-effective.

Without accurate as-built documentation, solar projects face significant risks and challenges. Maintenance teams must waste time investigating system layouts, repairs take longer and cost more, safety hazards may go undetected, regulatory compliance becomes difficult to prove, and future upgrades or expansions require extensive site surveys. Inaccurate or missing as-builts can lead to costly errors, project delays, failed inspections, and increased liability—making them a critical investment in any solar installation's success.

As-built drawings should be updated continuously throughout the construction process, not just at project completion. As changes occur on-site—whether due to field conditions, design modifications, or unforeseen challenges—the documentation should be revised to reflect these updates in real-time. This ongoing approach ensures accuracy, helps catch problems early, keeps all team members informed, and results in final documentation that truly represents the completed installation without requiring extensive reconstruction of information after the fact.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

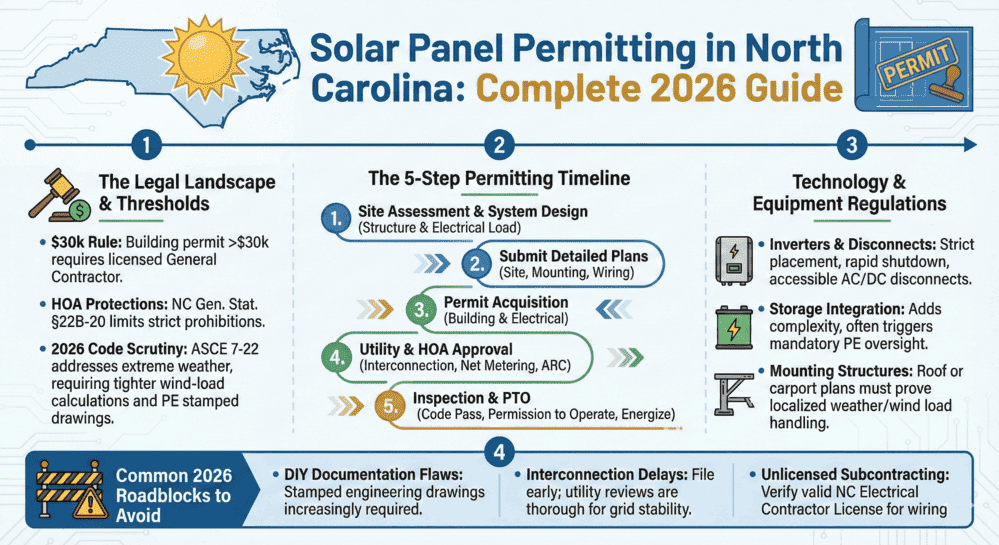

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...