Flat roof solar installations use two primary mounting systems: ballasted (weight-based) and attached (mechanically fastened). Ballasted systems secure panels using concrete blocks or ballast trays without roof penetrations, while attached systems use rails mechanically fastened to the roof deck with sealed penetrations.

Key Difference: Ballasted systems rely on weight for stability and avoid drilling into the roof. Attached systems use mechanical anchoring directly into the roof structure for superior wind resistance.

Ballasted systems work best for: Properties with strong roof structures in moderate wind zones, situations where avoiding roof penetrations is critical, and buildings where roof warranty preservation matters.

Attached systems work best for: Properties in high-wind coastal areas or severe weather zones, roofs with limited weight capacity, installations requiring maximum panel density, and regions with heavy snow loads or seismic activity.

Both mounting approaches successfully support flat roof solar installations when properly engineered for site-specific conditions. The optimal choice depends on roof structural capacity (ballasted requires 3-5+ pounds per square foot additional load), local climate patterns, building codes, and long-term maintenance preferences. This guide provides detailed comparison of both systems to help property owners select the right mounting solution.

Understanding Flat Roof Solar Panel Advantages

Flat roofs offer distinct advantages for solar panel installations. In roofing terminology, “flat” describes roofs with minimal slope (typically under 10 degrees) that still allow water drainage. This design creates an ideal platform for residential solar systems, providing several key benefits over traditional pitched roofs.

Customizable Panel Direction: Unlike pitched roofs where panels must follow the existing slope and orientation, flat roofs allow installers to position panels toward the optimal direction. This typically means true south in the United States, maximizing energy production throughout the day.

Enhanced Safety And Accessibility: Walkable flat roofs make installation processes faster and safer for crews. This accessibility also simplifies ongoing maintenance tasks like cleaning and system inspections.

Discreet Visual Profile: Panels mounted on flat roofs with low tilt angles and set back from edges remain less visible from street level. This provides aesthetic advantages for those preferring minimal visual impact.

Adaptable System Layout: The open surface of flat roofs enables customizable designs, particularly useful when working around vents, skylights, or other rooftop features. Installers can adjust spacing and stagger panel rows to eliminate shading while optimizing placement.

Essential Planning Factors For Flat Roof Solar Projects

Installing solar on flat roofs requires different planning than pitched roof projects. Without natural slope guiding the layout, every component demands careful consideration. Proper design ensures these systems perform as efficiently as sloped roof installations.

Angled Positioning Maximizes Solar Collection

Solar panels need proper angle positioning to capture sunlight effectively. The sun travels across the sky at varying angles throughout the day. Pitched roofs naturally provide this angle, but flat roofs require special mounting frames or tilt mechanisms to achieve optimal sun exposure.

Appropriate tilt also minimizes soiling, the accumulation of dust, pollen, and debris on panel surfaces. This buildup occurs more frequently on flat-mounted panels and can reduce system output over time, necessitating more frequent cleaning maintenance.

Row Arrangement Eliminates Self-Shading

Pitched roof panels typically follow the roof slope without creating shadows on adjacent panels, requiring minimal spacing between rows. Flat roof panels, however, sit at elevated angles that can cast shadows, especially during winter months when the sun sits lower in the sky.

Preventing self-shading requires wider spacing between panel rows in staggered configurations. This spacing also improves water flow across the roof surface and creates access lanes for inspections and future maintenance work.

Secure Anchoring Systems Resist Weather Forces

Pitched roof installations involve drilling mounting rails directly into the roof structure, then securing panels with clamps. Flat roof systems often utilize different approaches to achieve secure mounting while minimizing roof penetrations.

Both ballasted and attached systems must resist wind uplift, the force created when wind flows underneath panels and attempts to lift them. Areas experiencing high winds or heavy snow may require specific mounting solutions to ensure long-term system stability.

Drainage Planning Maintains Roof Performance

Flat roofs drain water more slowly than pitched surfaces, making proper drainage planning essential. Solar equipment must be positioned to avoid blocking drains, gutters, or low points where water collects. Equipment weight must be distributed evenly to protect the roof membrane and underlying structure. Poor system design risks water pooling, potentially causing leaks or structural damage.

Local Building Codes Shape Installation Requirements

All rooftop solar installations must comply with local building codes, but flat roof projects typically face more complex solar permit process. Fire safety regulations may mandate specific pathway configurations and wider setbacks from roof edges. Panel spacing requirements also vary based on local codes.

Weight-Based Ballasted Mounting Systems

Ballasted mounting systems represent one of the two primary approaches for flat roof solar installations. This method uses weight rather than roof penetrations to secure panels in place.

Understanding Ballasted Installation Methods

Ballasted systems rely on concrete blocks or gravel-filled trays to anchor solar panel racking without drilling into the roof surface. These systems rest on protective pads or supports that distribute weight evenly across the roof membrane, preventing damage.

While commonly associated with large commercial buildings, many residential properties can accommodate ballasted systems when the roof structure can handle the additional load. Engineering the system for local wind conditions is essential for successful implementation.

Benefits Of Weight-Based Mounting

No Roof Penetrations: Ballasted systems eliminate drilling through the roof surface, reducing leak risks and preserving roof warranty coverage in many cases.

Faster Installation: Without the need for extensive flashing and sealing work around penetrations, installation can proceed more quickly.

Roof Preservation: Avoiding penetrations maintains the integrity of the roofing membrane, particularly valuable for newer roofs or specialized roofing materials.

Future Removal: Systems can be removed without leaving permanent modifications to the roof structure, offering flexibility for future changes.

Drawbacks Of Ballasted Approaches

Weight Constraints: Not all roofs can support the substantial weight of ballasted systems. Structural assessment is mandatory before installation to verify load-bearing capacity.

Wind Exposure Concerns: Properties in high-wind zones may require additional ballast weight or alternative mounting methods to prevent system displacement.

Reduced Available Space: The weight distribution requirements and wider footprint of ballasted systems may reduce the total number of panels that can be installed compared to attached systems.

Climate Considerations: Regions with heavy snow accumulation may face additional challenges with ballasted systems due to combined weight loads.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Mechanically Fastened Attached Racking Systems

Attached racking systems provide the second major approach for flat roof solar installations, utilizing mechanical fastening to the roof structure for secure mounting.

Understanding Attached Installation Methods

This approach, standard on pitched roofs, adapts well for flat roof installations requiring enhanced structural anchoring. Mounting rails are mechanically fastened to the roof’s structural deck, and solar panels are secured to these rails using clamps with proper grounding techniques.

Each roof penetration receives careful sealing and flashing to prevent water intrusion. Attached systems often incorporate tilt frames or kits to improve solar exposure and reduce debris accumulation on panels.

Benefits Of Mechanically Fastened Mounting

Superior Wind Resistance: Mechanical fastening provides enhanced stability in regions with strong winds, severe weather, or seismic activity.

Lower Weight Load: Attached systems place significantly less weight on the roof structure compared to ballasted alternatives, making them viable for more buildings.

Maximized Panel Capacity: Without ballast footprint requirements, attached systems often allow more panels to fit in the available roof space.

Proven Long-Term Performance: The mechanical attachment method has decades of proven reliability across various climate conditions.

Drawbacks Of Attached Approaches

Roof Penetrations Required: Drilling through the roof creates potential leak points if not properly executed and maintained.

Installation Complexity: Proper flashing and sealing around each penetration requires skilled workmanship and extends installation time. Avoiding common installation mistakes is critical for system longevity.

Roof Age Considerations: Older roofs or those nearing replacement may not be ideal candidates for penetration-based mounting systems.

Professional Installation Critical: The waterproofing integrity of attached systems depends entirely on proper installation techniques.

Direct System Comparison: Making The Right Selection

Choosing between ballasted and attached mounting systems depends on multiple property-specific factors. Understanding these considerations helps property owners make informed decisions aligned with their circumstances.

Roof Structure And Condition

Ballasted Systems: Require roofs capable of supporting additional weight, typically 3-5 pounds per square foot or more depending on system design and wind requirements. Commercial installations may need structural reinforcement.

Attached Systems: Work with lighter weight requirements but need structurally sound roofing that can accommodate penetrations. Best suited for newer roofs or those recently replaced.

Local Climate And Weather Patterns

Ballasted Systems: Perform well in moderate wind zones but may require additional weight or alternative solutions in high-wind coastal areas or regions with severe weather events. Snow load must be factored into total weight calculations.

Attached Systems: Excel in areas with strong winds, heavy snow, or seismic activity where mechanical anchoring provides superior stability and long-term reliability.

Installation Timeline And Complexity

Ballasted Systems: Generally offer faster installation since extensive flashing and sealing work is unnecessary. The trade-off comes in equipment staging and weight distribution planning.

Attached Systems: Require more installation time for proper penetration sealing but avoid the logistical challenges of moving and placing heavy ballast materials.

Long-Term Maintenance And Flexibility

Ballasted Systems: Provide easier system removal if needed in the future and eliminate concerns about penetration maintenance over time. Regular inspection ensures ballast remains properly positioned.

Attached Systems: Require periodic inspection of flashing and sealants around penetrations to maintain waterproof integrity. System removal involves additional roof repair work.

Cost Considerations

Ballasted Systems: Material costs for ballast can add to overall project expenses, though reduced labor for penetration work may offset some costs. Structural assessment fees apply when load capacity evaluation is needed.

Attached Systems: Require investment in quality flashing materials and skilled labor for proper installation. Overall costs may be lower in some cases due to reduced material weight and simpler logistics.

Combined Mounting Strategies: Hybrid Solutions

Some installations benefit from hybrid mounting strategies that combine ballasted and attached elements. This approach uses attached mounting in high-stress areas (roof edges, corners) while employing ballasted systems in protected central zones.

Hybrid systems optimize the strengths of both approaches while minimizing their respective limitations. This solution works particularly well for larger roof areas or properties in transitional wind zones, as outlined in DOE solar guidelines.

Angle Adjustment Equipment: Enhancing Either System Type

Both ballasted and attached systems can incorporate tilt mechanisms to optimize panel angles. These metal frames adjust panel positioning, typically set at angles aligned with the property’s latitude for maximum sunlight capture in both grid-tied and off-grid applications.

Tilt mechanisms help panels shed debris more effectively than flat-mounted configurations, reducing soiling and maintenance requirements. Most residential systems use fixed tilt angles set during installation rather than adjustable mechanisms, following industry best practices.

Investment Analysis: Upfront Investment Versus Long-Term Value

Flat roof solar installations present unique cost dynamics compared to pitched roof projects. Understanding these factors helps set realistic budget expectations.

Initial Investment Considerations

Flat roofs can offer easier crew access, potentially reducing labor costs. However, this advantage often gets offset by additional equipment needs, mounting hardware expenses, structural assessments, and detailed design planning requirements.

The mounting system choice significantly impacts upfront costs. Ballasted systems require ballast material expenses, while attached systems need quality flashing and sealing materials plus skilled labor for penetration work and safety compliance.

Long-Term Value Proposition

Flat roofs provide a major advantage through installation flexibility. Panels tilted and oriented at optimal angles for sun exposure often capture more energy than fixed-slope roof installations. This increased energy production generates greater utility bill savings over the system’s lifetime.

Proper mounting system selection impacts long-term maintenance costs. Ballasted systems avoid penetration maintenance but require periodic ballast inspection. Attached systems need regular flashing and sealant checks to maintain waterproof integrity, as detailed in California permitting standards.

Selecting Experienced Installation Professionals

Flat roof solar installations demand specialized expertise beyond standard pitched roof experience. The mounting system selection, structural considerations, and AHJ requirements differ significantly from conventional installations.

Flat roofs are particularly common in urban areas throughout the Northeast, Midwest, Southwest, and cities. However, regions dominated by suburban pitched-roof homes may have fewer installers with comprehensive flat roof experience.

Working with installers familiar with both ballasted and attached mounting systems ensures access to the full range of design options. Solar Permit Solutions provides professionals who understand structural requirements, local permitting regulations, and the nuances of each mounting approach.

Qualified installers will conduct thorough site assessments, including structural evaluations, wind load calculations, and drainage analysis. They should present clear comparisons of mounting options with honest discussions of trade-offs specific to the property, adhering to ICC solar standards.

Determining The Optimal Mounting Choice For Your Property

Deciding between ballasted and attached mounting systems requires careful evaluation of property-specific factors. Neither approach is universally superior; the optimal choice depends on individual circumstances.

Choose Ballasted Systems When:

- Roof structure can support additional weight loads

- Avoiding roof penetrations is a priority

- Wind conditions fall within moderate ranges

- Future system removal may be desired

- Roof warranty preservation is important

- HOA approval needs aesthetic considerations

Choose Attached Systems When:

- Roof weight capacity is limited

- Property experiences high winds or severe weather

- Maximizing panel quantity is essential

- Roof is newer or structurally sound

- Long-term mechanical stability is prioritized

Consider Hybrid Systems When:

- Roof size allows for varied approaches

- Wind patterns vary across the roof surface

- Optimizing both cost and performance

- Structural capacity varies by roof section

Conclusion

Flat roofs are not barriers to solar adoption but rather opportunities for optimized installations. With proper mounting system selection and experienced installation professionals trained in flat roof solutions, flat roof solar arrays deliver flexible layouts, optimal panel orientation, and strong long-term performance.

Whether prioritizing system weight, wind resistance, installation speed, or future flexibility, both ballasted and attached mounting systems provide viable pathways to solar energy independence. The key lies in matching the mounting approach to specific property characteristics and long-term goals.

A well-designed flat roof solar system, utilizing the appropriate mounting strategy, can deliver reliable energy production and substantial utility savings for decades to come. Contact us to discuss your project requirements.

FAQs

Common practice tilts panels at angles close to the property’s latitude, facing toward the equator (south in the United States). This configuration maximizes sunlight capture across all seasons. Properties at higher latitudes (above 45 degrees) may benefit from slightly different angles based on local sun patterns and performance modeling. For more solar insights, visit our resource center.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Yes, solar panels install successfully on flat roofs and often provide more design flexibility than traditional pitched roofs. Since flat roofs lack built-in slope, installers use specialized mounting equipment to tilt panels for optimal sunlight exposure and reduced debris accumulation. With proper planning and equipment selection, flat roof solar systems deliver excellent performance.

Flat roof solar panels can match or exceed pitched roof performance. The ability to control panel orientation and tilt angle, rather than conforming to existing roof geometry, often results in superior energy production as demonstrated in institutional solar studies. Systems require careful planning to address shading, drainage, and wind challenges, making experienced installation critical for optimal results.

Ballasted systems involve material costs for concrete blocks or ballast trays, plus potential structural assessment fees. Attached systems require quality flashing materials and skilled labor for penetration sealing. Total costs depend on specific property factors, including roof condition, local wind requirements, and installation complexity. Both approaches offer good long-term value when properly matched to property characteristics and permit requirements.

The optimal mounting system depends on roof structural capacity, local climate conditions, building age, and long-term maintenance preferences. Properties with strong roof structures in moderate wind zones may benefit from ballasted systems. Buildings with weight limitations or exposure to severe weather typically require attached mounting. Professional structural assessment and site evaluation determine the most appropriate approach for both DIY and professional installations.

Installers design panel layouts to maximize annual sunlight exposure while meeting code requirements and protecting roof integrity. This includes determining optimal tilt angle, directional facing, and spacing to prevent shading while allowing proper drainage. Common practice tilts panels at angles close to the property's latitude, facing toward the equator (south in the United States). This configuration maximizes sunlight capture across all seasons. Properties at higher latitudes (above 45 degrees) may benefit from slightly different angles based on local sun patterns and performance modeling. For more solar insights, visit our resource center.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

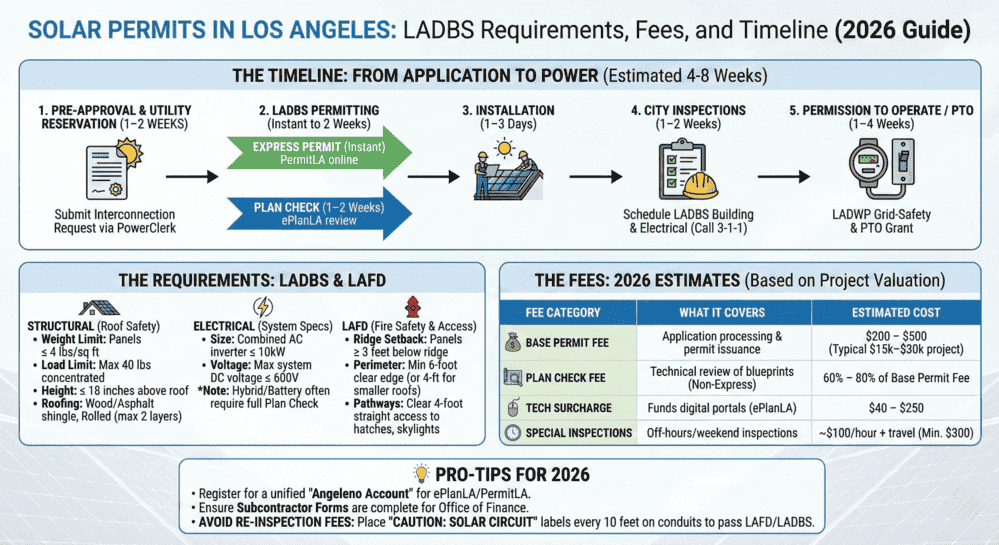

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...

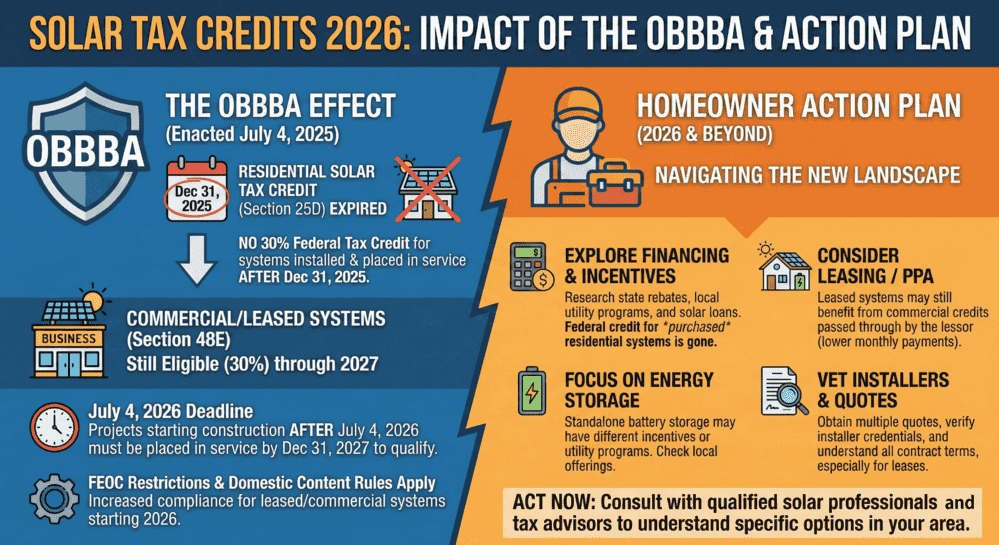

Solar Tax Credits 2026: What Changed After OBBBA and What Homeowners Can Do Now

Summary: The federal residential solar tax credit (Section 25D) expired December...

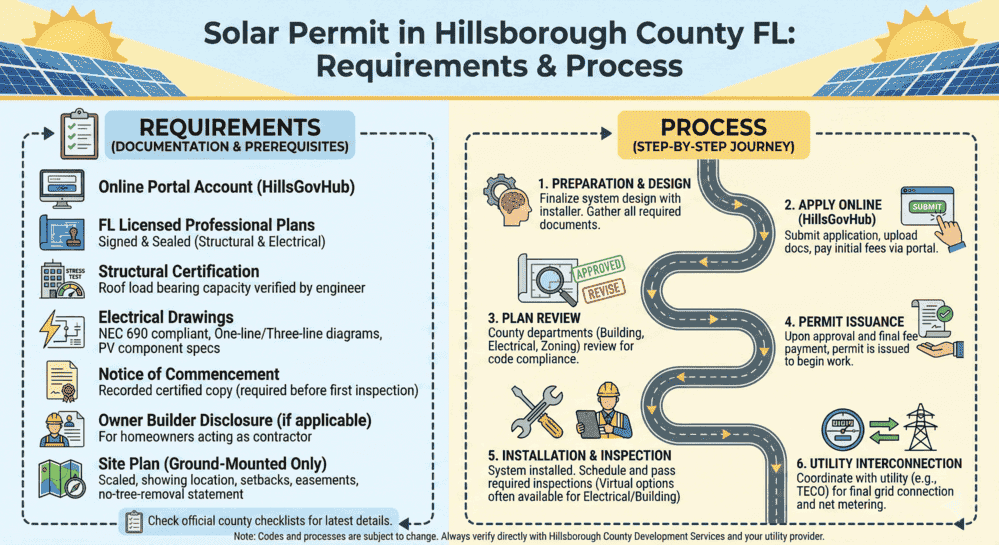

Solar Permit in Hillsborough County FL: Requirements & Process

Hillsborough County solar permits require either an Electrical Trade permit for ...