Grounding and bonding are two distinct safety requirements for solar photovoltaic systems. Grounding connects electrical components to Earth at zero voltage potential. Bonding connects metal equipment parts together to establish electrical continuity and prevent electric shock.

Most solar installation inspections fail due to improper grounding and bonding. All PV equipment must be grounded per NEC 250.4(A)(2), but not all electrical systems require grounding. The electrical system itself can be either grounded or ungrounded according to NEC 690.41.

Modern solar installations use several key safety components. UL 2703 listed racking systems bond modules together without drilling frame holes. Ground fault protective devices detect and isolate faults per NEC 690.41(B). Equipment grounding conductors must be sized per NEC 250.122 and run with circuit conductors.

Understanding grounding versus bonding prevents costly inspection failures. Grounding establishes connection to Earth potential and protects against lightning and voltage surges. Bonding creates electrical continuity between metal components and ensures no voltage difference exists between equipment enclosures. These safety circuits protect both people and property from electrical hazards including fires, equipment damage, and electric shock.

What Is Grounding in Solar PV Systems?

Grounding means connecting electrical components to the ground or Earth. The 2020 National Electrical Code (NEC) Section 250.4(A)(1) defines grounding as connecting to ground or to a conductive body that extends the ground connection. This brings all grounded components to the same voltage potential as Earth, which is set at zero volts.

Grounding protects solar systems by limiting voltage potential from lightning strikes, contact with higher voltage lines, and similar electrical events. System grounding typically occurs at the service point or at the first disconnecting means in a separately derived system.

All electrical equipment requires grounding according to NEC 250.4(A)(2). However, only certain electrical systems need to be grounded. The specific requirements are found in NEC sections 250.20 through 250.26.

What Is Bonding in Solar PV Systems?

Bonding means connecting metal parts of electrical equipment together to establish electrical continuity. The NEC defines bonding as connecting to establish electrical continuity and conductivity. This process brings bonded components to the same voltage potential, regardless of the magnitude of that potential.

All normally non-current-carrying metal parts of electrical equipment require bonding together per NEC 250.4(A)(3) and (B)(2). Bonding creates an effective ground fault current path. This ensures that when touching the metallic enclosures of two adjacent pieces of electrical equipment, no voltage potential exists between them or between either of them and Earth.

The Earth is not considered an effective ground fault current path per NEC 250.4(A)(5). Instead, fault current travels from the fault site through the metallic pieces of bonded electrical equipment, through the main bonding jumper, and finally through the grounded service conductor back to the transformer.

NEC 690.41(A): System Grounding Configurations

No, not all solar PV systems require grounding. All PV equipment must be grounded per NEC 250.4(A)(2), but the electrical system itself can be either grounded or ungrounded. Most modern PV systems in the United States use ungrounded configurations with non-isolating inverters.

Ungrounded PV systems have been used in Europe for decades. They became popular in the United States about a decade ago when non-isolating inverters gained widespread adoption. Ungrounded systems are more efficient than grounded systems, which is why they are now the most common configuration for new installations.

Solar PV systems can still be grounded per NEC 690.41(A)(1) and (5) if desired or required by specific circumstances. For grounded PV systems, the DC grounded conductor is directly coupled or coupled through electronic circuitry to the AC grounded conductor, which is then brought to ground potential by terminating to the neutral bus bar at the main service panel.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

How to Bond Solar Panels Using Metal Racking Systems

Modern metallic PV racking systems can be used to bond solar panels together. Many racking systems carry UL 2703 listings specifically to support and bond PV modules. This eliminates the older practice of drilling and tapping holes in the aluminum frame of each module and connecting those frames with bare copper conductors.

The old method had problems. Installers sometimes used connectors made of incorrect materials that would corrode due to their position relative to copper in the galvanic series. Module frames exposed to weather also developed aluminum oxide layers that acted as electrical insulation and compromised the connection integrity.

When using UL 2703 listed racking systems to bond modules, only an equipment grounding conductor needs to run from the array back to the main service panel. This equipment grounding conductor must run with the circuit conductors per NEC 690.43(C) and be sized per NEC 250.122. If the equipment grounding conductor is smaller than No. 6 AWG, it requires protection from physical damage per NEC 250.120(C).

Is a Separate Grounding Electrode Required for Solar Arrays?

No, a separate grounding electrode system is not required for PV arrays. This applies to both grounded and ungrounded PV system configurations. Previously, common practice required installing a grounding electrode conductor from the array to its own grounding electrode or to the premises grounding electrode system.

While a separate grounding electrode system remains permitted for a PV array per NEC 690.47(B), it is now optional. If a separate grounding electrode system for the array is installed, it must be bonded to the premises grounding electrode system per NEC 250.58. Bonding all separate grounding electrodes together limits the voltage potential between them per NEC 250.60.

Some contractors who are accustomed to grounding the system at the inverter still prefer to install a grounding electrode conductor at that point. While this is permitted per NEC 690.47(B), it serves only for grounding the PV equipment and not for grounding the PV system. For questions about your specific installation, contact our team for expert guidance.

NEC 690.41: Ground Fault Protection Requirements

Direct current ground fault protection must be installed per NEC 690.41(B) to reduce fire hazards in PV arrays. Ground fault protective devices (GFPDs) serve four required functions. They must detect ground faults in the DC conductors of a PV system including functionally grounded conductors. They must isolate faulted circuits from ground reference. They must indicate the occurrence of ground faults. They must be listed for the application.

Ground fault protection can be integrated into inverters or combiner boxes, or it can be installed as a separate device. The method of ground fault protection depends on whether the array configuration is grounded and how it is grounded.

For ungrounded PV arrays, which are the most popular configuration in the United States today, providing ground fault protection is especially important. Without ground fault protection, there would be no way of detecting a ground fault in the array, which could lead to fire hazards.

Why Do Solar Installation Inspections Fail Due to Grounding Issues?

Most solar installation inspections that fail do so because of improperly designed and installed grounding and bonding systems. These safety circuits are complex and often misunderstood by installers. Understanding regional requirements can help avoid common pitfalls. The consequences of improper grounding and bonding can be severe, which is why inspectors scrutinize these aspects carefully.

Common mistakes include creating parallel grounding pathways, which are prohibited per NEC 250.30(A). Installers may use incorrect conductor sizes, fail to properly bond equipment, or overlook NEC requirements for specific configurations. These errors can lead to system malfunctions, fires, or electric shock hazards.

The moment an electrical fault develops is not the time to discover that safety circuits are inadequate. Grounding and bonding form the foundation of electrical safety in solar installations. Proper installation protects both people and property from potentially catastrophic failures.

Conclusion

Proper grounding and bonding in solar photovoltaic systems go beyond simple regulatory compliance. They represent the fundamental safety infrastructure that protects both people and property from electrical hazards that could result in fires, equipment damage, or fatal electric shock.

Understanding the critical distinction between grounding and bonding is essential for anyone involved in solar installations. Grounding establishes a connection to Earth potential, limiting dangerous voltage levels during fault conditions. Bonding creates electrical continuity between metal components, ensuring that no voltage difference exists between equipment enclosures that people might touch.

The solar industry has made significant advances in simplifying these requirements. Modern UL 2703 listed racking systems with integrated bonding capabilities have eliminated many labor-intensive steps. Non-isolating inverters and sophisticated ground fault protective devices have improved both safety and system efficiency. However, these technological improvements do not reduce the importance of precise adherence to National Electrical Code requirements.

Whether designing a grounded or ungrounded PV array, selecting string inverters, or installing ground fault protection devices, every component serves a vital function in the overall safety circuit. Cutting corners or treating these requirements as optional can lead to serious consequences including inspection failures, system malfunctions, fire hazards, and potentially life-threatening electrical faults.

The permitting and inspection process exists as a critical safeguard in the solar installation workflow. Installers, system designers, and inspectors must maintain vigilance in applying grounding and bonding principles correctly. Each installation must meet the established standards that protect lives and property.

By understanding these requirements and the reasoning behind them, solar professionals ensure that every installation is not only compliant but genuinely safe. This commitment to proper grounding and bonding practices allows the solar industry to continue growing responsibly while maintaining the highest safety standards.

FAQs

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Grounding connects electrical components to the Earth, establishing a zero voltage potential reference point. This protects against overvoltage events like lightning strikes and contact with higher voltage lines. Bonding connects all metal equipment enclosures together to establish electrical continuity, creating an effective ground fault current path. The key difference is that grounding deals with voltage potential relative to Earth, while bonding ensures all metal parts maintain the same voltage potential to prevent electric shock hazards when someone touches equipment.

No, not all solar PV systems require grounded electrical circuits. While all PV equipment must be grounded according to NEC 250.4(A)(2), the electrical system itself can be either grounded or ungrounded. Most modern residential and commercial PV systems installed in the United States use ungrounded configurations with non-isolating inverters because they are more efficient. However, systems can still use grounded configurations per NEC 690.41(A)(1) and (5) when required by specific circumstances or installer preference.

Yes, you can use metal mounting racks to bond solar panels together if the racking system is properly listed. Many modern metallic PV racking systems carry UL 2703 listings specifically for supporting and bonding PV modules. These systems eliminate the outdated practice of drilling holes in module frames and connecting separate bonding wires between each panel. However, you must still install an equipment grounding conductor from the array back to the main service panel, sized according to NEC 250.122. This equipment grounding conductor must run with the circuit conductors per NEC 690.43(C).

No, a separate grounding electrode system is not required for solar arrays under current NEC requirements. This applies to both grounded and ungrounded PV system configurations. While you are permitted to install a separate grounding electrode system for the array per NEC 690.47(B), it is entirely optional. If you choose to install a separate grounding electrode system, you must bond it to the premises grounding electrode system per NEC 250.58 to limit voltage potential differences between the two electrode systems.

A ground fault protective device (GFPD) must perform four critical functions according to NEC 690.41(B). First, it must detect ground faults in the DC conductors of the PV system, including functionally grounded conductors. Second, it must isolate faulted circuits from the ground reference to prevent continued fault current flow. Third, it must indicate when a ground fault has occurred, typically through a visual indicator or alarm on the inverter display. Fourth, the device must be listed for its intended application. GFPDs are essential for reducing fire hazards in PV arrays and can be integrated into inverters or installed as separate devices in combiner boxes or standalone enclosures.

Solar installation inspections frequently fail because grounding and bonding requirements are complex and often misunderstood by installers. These safety circuits are critical for preventing electrical faults, fires, and shock hazards, which is why inspectors examine them carefully. Common mistakes include creating prohibited parallel grounding pathways, using incorrectly sized conductors, failing to properly bond equipment enclosures, overlooking NEC requirements for specific configurations, and using materials that are not listed for their intended application. Since grounding and bonding failures may not become apparent until a dangerous fault condition occurs, inspectors must ensure these systems are installed correctly before approving any solar installation.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

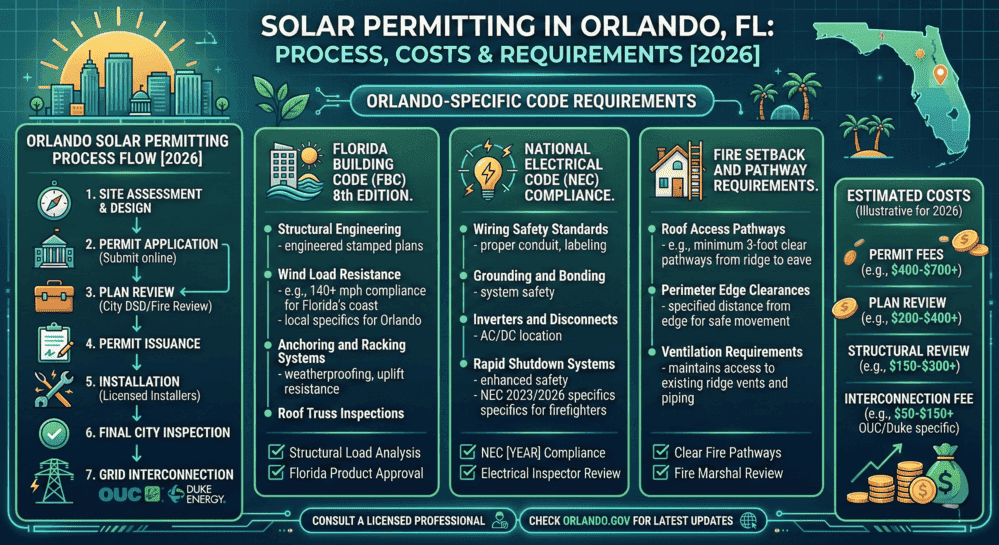

Solar Permitting in Orlando, FL: A Complete Guide for Homeowners & Installers

Solar permitting in Orlando, FL, requires a building permit and an electrical pe...

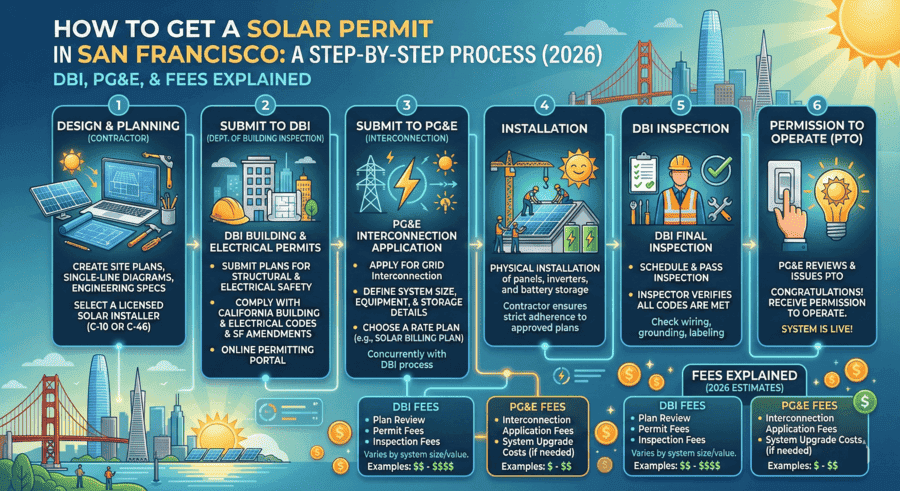

How To Get A Solar Permit In San Francisco: DBI, PG&E And Fees Explained (2026)

San Francisco solar permits require two separate approvals before your system ca...

Bifacial Solar Panel Installation And Permitting Guide

Bifacial solar panels generate 10 to 30 percent more energy than traditional mon...