NEC 690.16 establishes fuse servicing requirements for solar photovoltaic systems to protect technicians from electrical shock and arc flash hazards. This code section was consolidated into NEC 690.15 starting with the 2017 edition but the safety requirements remain mandatory under current provisions.

Key Requirements:

- Disconnecting means must isolate fuses from all supply sources when energized from both directions (Section 690.16(A))

- Disconnects must be within sight of fuse locations, defined as visible and not more than 50 feet away (Section 690.16(B))

- Touch-safe fuse holders meet code requirements but must be labeled “Do not open under load” when lacking load-break ratings

- DC circuit breakers eliminate fuse servicing requirements entirely since the code only mandates disconnects when fuses exist in circuits

- Only gPV-rated fuses certified to IEC 60269-6 and UL 2579 standards are permitted for solar PV applications

Why These Requirements Exist: Solar PV fuses remain energized from multiple sources simultaneously. Even when inverters shut down, solar modules continue generating voltage during daylight hours, creating dangerous conditions during maintenance. This dual-energization scenario requires specific disconnecting means to ensure safe fuse replacement without exposing technicians to live circuits.

Three Compliant Solutions:

- Touch-safe fuse holders with integrated DC disconnects in string combiners

- DC subcombiner circuit breakers that eliminate fuses entirely

- Strategic positioning of combiners within 50 feet of inverters for dual-purpose disconnects

The National Electrical Code continues to evolve with enhanced safety requirements for solar photovoltaic installations. While Article 690 has undergone numerous revisions across different code cycles, understanding fuse servicing requirements remains essential for safe PV system operation and maintenance.

Historical Context Of Fuse Servicing Requirements

The 2011 edition of the National Electrical Code introduced specific provisions within Article 690 addressing fuse servicing safety concerns. These requirements emerged from real-world incidents where technicians encountered electrical shock risks and arc flash hazards while servicing fuses in photovoltaic systems.

Code Making Panel 4 assumed responsibility for processing Articles 690 and 705 starting with the 2011 NEC cycle. The panel focused on clarifying existing requirements and addressing unique safety challenges presented by current-limited DC generators and utility-interactive AC sources in solar installations.

The Core Challenge Of PV Fuse Servicing

Fuses integrated within inverters or string combiners can remain energized from multiple sources simultaneously. Shutting down the inverter does not eliminate all energy sources from DC fuses. During daylight hours, PV modules continue energizing circuits even when the inverter operates in off mode and fuses carry no current.

When a fuse requires replacement while the PV array remains connected to the combiner, that fuse stays live and presents significant electrical hazards. This dual-energization scenario created the need for specific disconnecting means requirements.

NEC 690.16 Requirements Overview

Section 690.16(A) Disconnecting Means

Systems must provide disconnecting means to isolate fuses from all supply sources when fuses receive energization from both directions. For fuses located in PV source circuits, the disconnecting means must enable independent isolation from fuses in other PV source circuits.

This requirement ensures technicians can safely service individual fuse locations without de-energizing entire array sections or creating hazardous working conditions.

Section 690.16(B) Fuse Servicing Disconnects

Installations must include disconnecting means on PV output circuits where overcurrent devices require servicing but cannot be isolated from energized circuits. The disconnecting means must be positioned within sight of the fuse location or integral with the fuse holder.

The code defines “within sight” as visible and not more than 50 feet from the specified location. Non-load-break-rated disconnecting means require labeling with “Do not open under load” warnings.

When the disconnect location exceeds 6 feet from the fuse, a directory must identify the fuse disconnect location at the fuse site.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Touch-Safe Fuse Holder Solutions

Touch-safe fuse holders provide one method for meeting fuse servicing requirements. These holders enable safe fuse removal from all energy sources while protecting technicians from accidental contact with live terminals during replacement procedures.

However, touch-safe fuse holders typically lack load-break ratings and require explicit labeling requirements stating “Do not open under load.” Opening these holders under load creates dangerous arc flash hazards.

Proper Touch-Safe Fuse Servicing Procedure

Safe fuse servicing with touch-safe holders requires the following steps:

- Turn off the DC disconnect integrated with the string combiner

- Verify current absence using a DC clamp meter

- Open the touch-safe fuse holder after confirming de-energization

- Remove and replace the fuse

- Reverse the process to restore operation

Combining DC disconnects with touch-safe fuse holders in disconnecting string combiners provides convenient methods for maintaining fuses within combiner boxes while meeting code requirements. Proper shading analysis during design helps minimize system issues that could lead to frequent fuse servicing.

Alternative Solutions For Fuse Servicing Compliance

DC Subcombiner Circuit Breakers

The most cost-effective approach to resolving fuse servicing disconnect requirements involves eliminating fuses from inverter subcombiners entirely. The code only mandates disconnects when fuses exist in the circuit. Without fuses, no DC disconnects need placement adjacent to inverters for servicing purposes.

Subcombiners integral to inverters that incorporate DC breakers deliver necessary overcurrent protection while eliminating fuse servicing disconnect needs. DC subcombiner breakers reduce additional components and labor costs compared to external disconnect installations.

PV output circuit conductors terminate at lugs installed on circuit breakers inside the inverter. Purchasing inverters with integrated subcombiner DC breakers simplifies system design and installation while increasing safety, reliability, and installation speed.

Strategic Combiner Positioning

Another compliant solution positions all disconnecting string combiners within 50 feet of the inverter. The disconnect then serves dual purposes by breaking the load for touch-safe fuse holders in the string combiner box while de-energizing associated subcombiner fuses when used with the main inverter DC disconnect.

However, routing each PV source circuit conductor from the array to string combiners within 50 feet of inverters becomes physically and financially impractical for large-scale installations.

Code Evolution Beyond 2014

The 2017 NEC eliminated the specific language of Section 690.16 through a comprehensive rewrite of Section 690.15, which addresses equipment disconnects generally. The fuse isolation requirement remains mandatory for safe replacement operations but now falls under broader equipment disconnect provisions.

This consolidation simplified code navigation while maintaining essential safety protections for technicians servicing PV system overcurrent devices. For detailed guidance on commissioning and acceptance, reference official government resources.

Load-Break Versus Interrupting Ratings

Understanding the distinction between load-break ratings and interrupting ratings proves critical for proper equipment selection:

Load-break rating measures device ability to interrupt maximum current under normal operating conditions. These ratings account for routine switching operations without fault conditions present.

Interrupting capacity measures device ability to interrupt maximum current during fault conditions. These ratings address worst-case scenarios where equipment must safely handle short-circuit currents.

These represent fundamentally different ratings serving distinct safety functions. Touch-safe fuse holders meeting code requirements must provide adequate interrupting capacity while including appropriate labeling when lacking load-break capabilities.

Installation And Compliance Best Practices

Fuse Sizing Requirements

NEC 690.8(A)(1) requires sizing conductors and overcurrent devices at 156% of short-circuit current under standard test conditions. This multiplier accounts for irradiance variation, temperature effects, and aging factors affecting PV system performance.

The minimum fuse rating calculation follows this formula:

Minimum Fuse Rating = Module Isc × 1.56

Never round down when selecting fuse ratings. Maximum fuse size must not exceed conductor ampacity or equipment ratings to maintain proper protection.

Proper Fuse Selection

Only use fuses tested and certified to IEC 60269-6 and UL 2579 standards in solar applications. Standard DC or automotive fuses cannot safely interrupt reverse photovoltaic currents and may explode under fault conditions.

Using non-gPV rated fuses in solar applications violates NEC Article 690.9 and creates serious safety hazards. These specialized fuses provide essential protection against reverse currents unique to photovoltaic systems.

Installation Considerations

Proper installation ensures reliable operation and safe servicing:

Orientation: Vertical mounting with connections facing downward prevents moisture accumulation in outdoor installations while most fuse holders operate in any position.

Accessibility: Install fuses in locations enabling safe replacement without roof climbing or entering energized equipment areas. NEC 690.15 requires readily accessible disconnecting means.

Connection Integrity: Use calibrated torque screwdrivers for critical connections. Under-tightening creates high-resistance connections that heat under load, while over-tightening damages terminals and conductors.

Conductor Preparation: Strip wire insulation 10-12mm for screw terminals. Use ferrules on stranded wire to prevent strand breakage and ensure solid contact. Proper conduit selection also supports safe installations.

Authority Having Jurisdiction Considerations

Project-specific questions regarding fuse servicing disconnect compliance should be directed to the authority having jurisdiction. Different jurisdictions enforce different NEC editions, and AHJs may interpret requirements differently based on local conditions and experience.

Fused subcombiners integral to inverters with single disconnects located after DC fuses combine on the DC bus do not de-energize fuses from all sources and alone do not satisfy code requirements. Additional disconnecting means may be required for each subcombiner fuse location.

Conclusion

Fuse servicing requirements represent a critical safety component in solar photovoltaic system design and maintenance. The evolution of NEC Article 690.16 through various code cycles demonstrates the electrical industry’s commitment to protecting technicians from electrical shock and arc flash hazards during routine maintenance operations.

Whether implementing touch-safe fuse holders with proper disconnecting means, transitioning to DC circuit breaker solutions that eliminate fuse servicing concerns entirely, or strategically positioning combiners within code-compliant distances, system designers have multiple pathways to achieving safe, compliant installations. Each approach offers distinct advantages depending on system scale, budget constraints, and site-specific installation conditions.

The consolidation of fuse servicing requirements into broader equipment disconnect provisions in the 2017 NEC and subsequent editions simplified code navigation without compromising safety standards. However, the fundamental principle remains unchanged: technicians must be able to safely isolate and service overcurrent protection devices without exposure to energized circuits from multiple sources.

As solar technology advances and code requirements continue evolving, staying informed about the latest NEC edition adopted in applicable jurisdictions ensures installations meet current safety standards. Proper fuse selection, correct sizing calculations using the 1.56 multiplier, and adherence to installation best practices create reliable systems that protect both equipment and personnel throughout decades of service life.

Consulting with authorities having jurisdiction early in the design process helps clarify interpretation questions and ensures project-specific solutions meet local enforcement expectations. This proactive approach prevents costly redesigns and installation delays while maintaining the highest safety standards for PV system maintenance operations. For additional technical resources and industry updates, visit the Solar Permit Solutions blog.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

The primary purpose addresses the unique safety challenge in PV systems where fuses can remain energized from multiple sources simultaneously. Even when inverters are shut down, solar modules continue generating voltage during daylight hours, creating electrical shock and arc flash hazards during fuse replacement. The requirements ensure technicians can safely isolate fuses from all energy sources before servicing, protecting workers from potentially fatal electrical contact.

Touch-safe fuse holders meet code requirements when properly implemented with appropriate disconnecting means. However, touch-safe holders typically lack load-break ratings and must be labeled "Do not open under load." The proper procedure requires turning off the DC disconnect, verifying zero current flow with a DC clamp meter, then opening the touch-safe holder. If a disconnect lacks load-break capability, never open it under load conditions. For applications requiring load-break functionality, specify equipment rated for those operations or consider DC circuit breaker alternatives.

Yes, by removing fuses from the system design and replacing them with DC circuit breakers. NEC 690.16 requirements only apply when fuses exist in the circuit. Subcombiners integral to inverters that use DC breakers provide necessary overcurrent protection while eliminating fuse servicing disconnect requirements entirely. This approach reduces component count, lowers installation labor costs, and simplifies system design while maintaining code compliance and safety standards.

The disconnecting means must be within sight of the fuse location, which the NEC defines as visible and not more than 50 feet away. If the disconnect location exceeds 6 feet from the fuse, installers must provide a directory at the fuse location showing where to find the disconnect. For integral fuse holder designs, the disconnect mechanism is built directly into the fuse holder assembly, eliminating distance concerns. When planning combiner box and disconnect locations, position equipment to minimize distances while maintaining accessible, safe working conditions.

Solar PV systems require gPV-rated fuses specifically tested and certified to IEC 60269-6 and UL 2579 standards. Standard DC fuses or automotive fuses cannot safely interrupt reverse photovoltaic currents and may explode under fault conditions. Using non-gPV rated fuses violates NEC Article 690.9 and creates serious safety hazards. When sizing fuses, apply the 1.56 multiplier to the module short-circuit current per NEC 690.8(A)(1), and never round down when selecting the next available fuse rating. The additional cost of proper gPV-rated fuses is minimal compared to fire risks and liability exposure from using incorrect overcurrent devices.

The specific Section 690.16 language was eliminated in the 2017 NEC when the code underwent a comprehensive rewrite. However, the fuse servicing and isolation requirements were not removed but rather consolidated into Section 690.15, which addresses equipment disconnects more broadly. The safety requirements remain mandatory under current code provisions. Technicians must still be able to safely isolate and service fuses, but the requirements now fall under general equipment disconnect provisions rather than a standalone section. This consolidation simplified code organization while maintaining essential worker protection standards.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

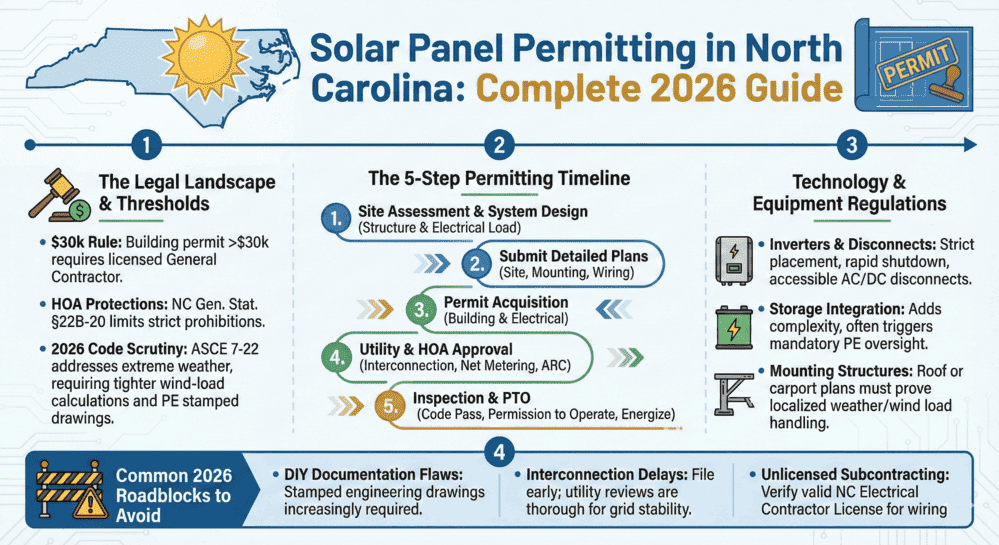

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...