Solar conductor sizing determines wire thickness based on current load, voltage drop limits, and safety requirements. The National Electrical Code (NEC) recommends keeping voltage drop below 3% for individual DC or AC circuits and 5% total system drop from array to load. NEC Article 690 requires conductors to handle 125% of maximum circuit current for continuous solar loads.

International Electrotechnical Commission (IEC) standards, including IEC 60364 and IEC 62548, use metric wire measurements (mm²) instead of American Wire Gauge (AWG) and typically recommend 3-5% voltage drop limits depending on application. Both standards share the same goal: preventing power loss, equipment failure, and safety hazards caused by undersized wiring.

Proper conductor sizing accounts for five critical factors: current-carrying capacity (ampacity), conductor length, wire gauge, material type (copper vs aluminum), and ambient temperature. Incorrect sizing causes excessive heat buildup, reduced energy production, inverter malfunctions, and potential fire risks. Each percentage point of voltage drop translates directly to lost revenue and decreased system efficiency over the installation’s lifetime.

What Causes Voltage Drop In Solar Conductors

Voltage drop represents the decrease in electrical potential as current flows through a conductor. This phenomenon resembles pressure loss in a plumbing system. While some degree of voltage drop remains inevitable, excessive levels prevent equipment from receiving adequate power, resulting in reduced energy production and accelerated component deterioration.

Why Voltage Drop Matters For Solar Power Systems

Solar energy systems experiencing substantial voltage drop between photovoltaic arrays and inverters force inverters to operate beyond their ideal Maximum Power Point Tracking (MPPT) range. This imbalance decreases total power generation. Elevated voltage drop converts potential electrical energy into wasted thermal energy within cables. Additionally, inverters may experience nuisance trips when input voltage drops below minimum operational thresholds.

Critical Factors That Determine Solar Cable Size

Multiple elements determine appropriate conductor dimensions for solar applications. Overlooking these factors results in compromised system design. Critical considerations include:

Current-Carrying Capacity: The maximum current a wire can safely conduct without surpassing temperature limits.

Distance Between Components: Extended wire runs produce increased voltage drop.

Wire Thickness: Larger diameter wires (lower gauge numbers) offer reduced resistance and minimal voltage drop.

Conductor Material: Copper demonstrates lower resistance compared to aluminum at equivalent sizes, providing superior conductivity.

Environmental Temperature: Elevated ambient conditions increase conductor resistance, diminishing effective current capacity.

How The National Electrical Code Addresses Solar Wiring

The National Electrical Code establishes fundamental electrical installation requirements throughout North America. While enforcing strict safety protocols, voltage drop guidance typically appears as recommendations rather than absolute requirements.

NEC Recommended Limits For PV System Voltage Drop

The NEC presents suggested voltage drop thresholds to maintain reasonable system efficiency. Standard best practices, referenced in NEC Informational Notes, include:

Circuit Section | Recommended Maximum Voltage Drop

- PV Source & Output Circuits (DC Side): 3%

- Inverter Output Circuit (AC Side): 3%

- Total from PV Array to Load: 5%

Following these percentages ensures equipment receives sufficient voltage while minimizing energy waste. Local Authorities Having Jurisdiction (AHJs) retain authority to mandate these recommendations.

Calculating Wire Size Using NEC Article 690

NEC Article 690 addresses photovoltaic system requirements specifically. The sizing methodology involves determining maximum circuit current and implementing adjustment factors. Conductors must handle 125% of calculated maximum current to accommodate continuous loads. Additional adjustments account for ambient temperature and multiple current-carrying conductors within shared conduits, which generate heat and reduce wire capacity.

International Electrical Standards Beyond North America

Beyond North America, International Electrotechnical Commission standards serve as primary guidelines. The IEC methodology emphasizes performance-based approaches, ensuring systems function properly under all anticipated conditions.

How IEC Standards Calculate Conductor Requirements

IEC standards, including IEC 60364 (Electrical Installations for Buildings) and IEC 62548 (Photovoltaic Arrays – Design requirements), supply detailed tables and formulas for conductor calculations. These standards prove essential for successful renewable energy grid integration. Calculations consider conductor current capacity, installation techniques, and acceptable voltage drop, typically recommended below 3-5% depending on application type (such as lighting versus motor circuits).

Key Differences Between IEC And NEC Approaches

While electrical principles remain constant, methodology and terminology differ between standards. The IEC employs metric wire measurements (mm²) rather than American Wire Gauge (AWG) designations. IEC ampacity tables comprehensively address numerous installation configurations (including wall mounting, tray systems, and underground burial). The fundamental voltage drop formula remains universal, though specific resistance values and correction factors appear in IEC documentation. Standardized guidelines prove critical for reliable power system operation with substantial variable renewable energy integration.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Unified Goals Across All Electrical Standards

Regardless of applicable standards, objectives remain identical: safe, efficient, and long-lasting solar installations. Well-engineered systems minimize resistive losses (I²R losses), maximizing solar energy conversion into usable electricity.

How Wire Sizing Affects Solar System Revenue

Every conductor sizing decision directly impacts financial returns. A 2% voltage drop equates to a 2% reduction in potential revenue or energy savings. Properly dimensioned conductors provide cost-effective protection against long-term performance degradation.

Beyond Basic Calculations: Thermal And Safety Factors

Large-scale or complex installations require evaluation of additional factors, including short-circuit current ratings and conductor behavior at elevated temperatures. Utilizing conductors rated for higher operating temperatures increases power transmission capacity in major PV feeders, where thermal management proves essential for optimizing power delivery.

Engineering Excellence In Solar Installation Design

Mastering solar conductor sizing under NEC and IEC standards extends beyond regulatory compliance. The practice represents engineering excellence. Through careful voltage drop calculations and appropriate conductor selection, solar energy systems deliver reliable, clean power as designed. This thorough approach ensures extended equipment life, maximized energy generation, and secure electrical environments.

Disclaimer

This content provides general information and does not replace professional engineering or electrical consultation. Always engage qualified professionals and comply with local codes and regulations when designing solar systems. Licensed electricians must perform all electrical work.

Conclusion

Proper solar conductor sizing forms the foundation of safe, efficient photovoltaic installations. Whether following NEC Article 690 in North America or IEC 60364 internationally, maintaining voltage drop below recommended thresholds (3% per circuit section, 5% total) directly impacts system performance and financial returns.

Success requires balancing multiple factors: wire ampacity, gauge selection, conductor material, installation method, and temperature derating. While NEC provides informational recommendations enforced by local authorities, IEC offers performance-based requirements with metric measurements. Both standards ultimately ensure conductors safely handle required currents while minimizing resistive losses and maximizing energy harvest over decades of operation.

FAQs

Need help with Solar Permit Solutions? Contact our team or explore our blog for more expert guidance on permit expediting and compliance requirements.

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Standard practice, aligned with NEC recommendations, limits voltage drop to 3% for individual circuit sections (DC or AC side) while maintaining total voltage drop from solar panels to end use below 5%.

Within the NEC, voltage drop limits appear in 'Informational Notes,' designating them as recommendations rather than mandatory code provisions. However, local authorities (AHJs) maintain final approval authority and may enforce these limits as approval conditions to guarantee system performance and efficiency.

Elevated temperatures increase wire electrical resistance. This reduces a conductor's current-carrying capacity (ampacity) in hot environments, such as rooftop installations. Sizing calculations must incorporate temperature correction factors to select wires capable of safe operation at maximum expected ambient temperatures.

The American Wire Gauge (AWG) system uses numbers where lower values indicate thicker wires (common in NEC applications). The IEC uses metric measurements in square millimeters (mm²) to indicate the cross-sectional area of conductors. Both systems measure the same physical property but use different scales.

Aluminum conductors can be used for solar installations, but they require larger wire sizes compared to copper to achieve the same current-carrying capacity and voltage drop performance. Aluminum has higher electrical resistance than copper. Additionally, all equipment terminals must be rated for aluminum connections (marked AL/CU), and proper installation techniques must be followed to prevent oxidation issues at connection points.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

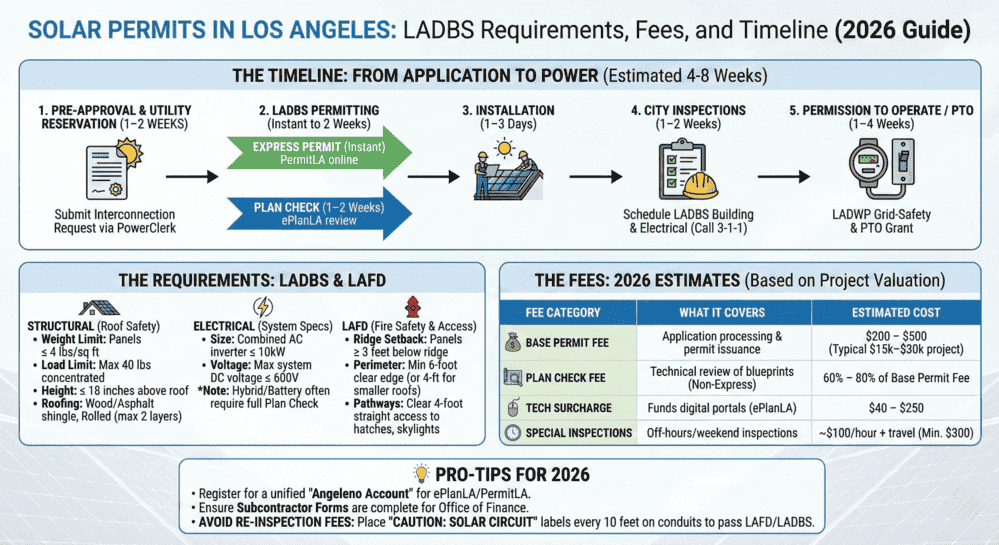

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...