Solar panel defects are equipment malfunctions that reduce photovoltaic system performance, with the most common types being discoloration, delamination, and diode failure. According to the 2025 Global Solar Report by Raptor Maps, hardware-related underperformance has increased 214% since 2019, resulting in $10 billion in lost energy value worldwide in 2024.

What are the most common solar panel defects? The seven primary defects include microcracks (tiny cell fractures from handling or thermal stress), delamination (layer separation allowing moisture intrusion), hotspots (localized overheating from shading or diode failure), snail trails (dark streaks from chemical reactions), solar panel diode failure (bypass diode malfunction causing 33%+ power loss), Potential Induced Degradation or PID (voltage stress causing current leakage), and discoloration (yellowing or browning from UV exposure and material degradation).

How do solar panel defects affect performance? These defects reduce system efficiency by 5% to 50% depending on severity, increase fire risk from overheating components, shorten panel lifespan by accelerating degradation, and cost property owners hundreds of dollars annually in lost energy production. Weather conditions including extreme heat, hailstorms, and high winds accelerate defect development in aging systems.

How can solar panel defects be detected? Regular monitoring reveals defects through declining energy output, visual inspection identifies discoloration and physical damage, thermal imaging detects hotspots and diode failures, and electroluminescence testing exposes invisible microcracks and delamination. Early detection through professional inspections protects system warranties and prevents costly repairs.

Property owners experiencing underperforming solar panels should seek expert services to restore energy output and maximize long-term savings.

Understanding Solar Panel Anatomy: Critical Components Behind Performance Issues

Understanding solar panel components helps diagnose performance issues and identify common defects. Problems such as solar panel discoloration, delamination, and diode failure often originate from degradation in one or more components. The following overview details essential parts and their contribution to solar panel damage over time.

Solar Cells: Photovoltaic (PV) cells convert sunlight into direct current (DC) electricity. These cells can crack or discolor over time, particularly from UV exposure or heat stress, both primary causes of solar panel defects and power reduction.

Frame: Rigid aluminum frames support panels and provide protection against mechanical damage. Bent or corroded frames, frequently caused by hail impact or salt exposure, enable water intrusion and contribute to long-term solar panel damage. Poor installation practices can exacerbate frame vulnerabilities.

Glass Cover: Tempered glass layers protect PV cells while permitting sunlight transmission. Cracks or cloudiness in glass reduce energy output and may cause visible solar panel discoloration, especially when combined with internal moisture penetration.

Encapsulation Layer: Clear protective layers surround solar cells, guarding against humidity and thermal cycling. Degraded or inferior encapsulation materials cause solar panel delamination, where protective layers separate and compromise performance.

Solar Panel Backsheet: Located on the panel’s rear surface, backsheets provide electrical insulation and supplementary protection. Backsheet cracking represents a known issue connected to solar panel defects and safety hazards.

Junction Box with Diodes: Junction boxes house electrical terminals and bypass diodes. Poorly sealed boxes allow water or heat damage to internal components, potentially causing solar panel diode failure or electrical shorts. Proper installation tools help ensure secure connections.

Solar Panel Diodes: Bypass diodes inside junction boxes prevent reverse current and overheating. Diode burnout or malfunction, classified as solar panel diode failure, can compromise entire module strings.

Busbars and Ribbons: Thin, conductive strips collect and transport electrical current from cells. Corrosion or microcracks lead to inconsistent output or panel damage.

Anti-reflective Coating: Applied to front glass surfaces, this coating minimizes sunlight reflection and improves absorption. Coating degradation may contribute to solar panel discoloration and reduced efficiency over time.

Edge Seal: Edge seals run around panel perimeters, preventing moisture, dust, and air from penetrating between glass and encapsulant layers. Degraded edge seals lead to solar panel delamination, discoloration, or internal component corrosion. This often represents a hidden failure that intensifies over time.

Heat Sink or Thermal Pad (in some advanced panels): Premium modules sometimes include thermal pads or heat-dissipating features that reduce component temperatures. Excessive heat accelerates numerous solar panel defects, including diode failure, delamination, and discoloration. Efficient thermal management extends system lifespan.

Detecting Solar System Problems: Visual Inspection And Performance Analysis

Solar panel damage significantly reduces system performance and shortens operational lifespan. Regular visual inspections and monitoring help identify common solar panel defects early, before they necessitate expensive repairs or replacements.

Identifying Drops In Solar Energy Output

Noticeable declines in energy production, particularly when weather conditions remain stable, often signal underlying problems. These include solar panel diode failure, delamination, or solar cell degradation. Comparing current system output against expected performance provides one of the most effective methods for detecting hidden equipment issues. Proper system sizing helps establish accurate performance baselines.

Recognizing Solar Panel Discoloration

Solar panel discoloration ranks among the most visible signs of potential damage. This typically manifests as brown, yellow, or purple stains on panel surfaces.

Discoloration frequently results from UV degradation, heat accumulation, or encapsulant layer problems. Over time, it interferes with light absorption, contributing to lower energy output and additional solar panel defects. When discoloration spreads or intensifies, professional inspection becomes necessary.

Solar Panel Diode Failure And Hotspots

Solar panel diode failure doesn’t always present obvious visual indicators, yet it creates serious consequences. Bypass diodes reroute current around shaded or damaged cells, protecting modules.

When diodes fail, hotspots form, creating localized overheating, visible burn marks, or fire hazards. Hotspots may also cause solar panel discoloration or cracked glass. Infrared imaging and electrical testing provide useful tools for identifying diode problems before they escalate. Advanced defect detection hardware continues to improve diagnostic accuracy.

Signs Of Solar Panel Delamination

Solar panel delamination occurs when module layers separate, often between glass, encapsulant, and backsheet components. This defect permits moisture and air entry into panels, leading to corrosion, diode failure, or short circuits.

Early delamination signs include cloudiness, bubbling, or blistering on panel surfaces. Delaminated panels experience greater susceptibility to solar panel damage and reduced lifespan, especially in systems exposed to extreme weather conditions.

Other Common Solar Panel Problems

Routine inspections frequently uncover common solar panel defects such as cracks, chips, or dust accumulation, all reducing sunlight absorption and causing decreased output. Surface damage represents a frequent cause of solar panel performance issues, particularly in aging systems or those exposed to harsh environments.

Electrical faults present another concern. Loose wiring, corroded terminals, and inadequate grounding result in power loss or safety hazards. Sometimes, solar panel diode failure or malfunctioning inverters represent the root cause of underperformance. Early issue identification prevents further solar panel damage, extends system life, and maintains optimal energy production. Understanding roof structural capacity also prevents installation-related defects.

Root Causes Behind Module Failures And Equipment Deterioration

Many common solar panel defects result from manufacturing flaws or extended environmental stress exposure. Problems including poor solder joints, weak glass or frame materials, faulty junction boxes, busbar corrosion, and inferior encapsulants all contribute to gradual solar panel damage and reduced performance.

These defects may not cause immediate failure but frequently shorten system lifespan and reduce energy output over time. Visual indicators such as solar panel discoloration, delamination, or overheating signs at junction boxes can point to underlying issues like moisture intrusion or solar panel diode failure.

Regular inspections and solar monitoring prove essential for early problem detection. Catching these solar panel defects before they escalate helps prevent performance losses, protects warranties, and reduces long-term repair expenses.

Solar Permit Solutions

Affordable Solar Permit Plans

Don't let permit costs slow your project. Professional plan sets at competitive prices — all 50 states, fast turnaround.

Visual Defects And Color Changes: A Comprehensive Breakdown

Solar Panel Snail Trails

Snail trails represent a visible form of solar panel discoloration appearing as thin, dark streaks or patterns on module surfaces. This solar panel defect results from chemical reactions within encapsulation materials, often triggered by moisture and oxygen presence. Over time, these reactions form conductive pathways that degrade panel electrical performance, especially when combined with microcracks or internal corrosion.

To identify snail trails, inspect panel surfaces in direct sunlight when these markings become easiest to spot. While snail trails don’t always cause significant output drops, they signal deeper solar panel defects and require monitoring. When panels remain under warranty, contacting manufacturers determines whether replacement based on performance degradation becomes warranted.

Hotspots On Solar Panels

Hotspots occur when specific cells within solar modules overheat due to localized shading, soiling, poor solder connections, or solar panel diode failure. This represents a serious issue, as overheating leads to permanent solar panel damage, including cell burn-through, cracked glass, and decreased system performance.

Thermal imaging during full sunlight provides the most effective hotspot identification method. They appear as bright or glowing regions compared to remaining panel areas. To prevent hotspot formation, regular cleaning and array maintenance prove essential. When hotspots link to faulty diodes or manufacturing issues, affected panels may require replacement to avoid further damage.

Shading And Shadowing

While not technically a solar panel defect, shading represents a common solar panel problem that dramatically reduces output, even when just one cell receives partial shade. Because cells connect in series, a single shaded area impacts entire module or string performance.

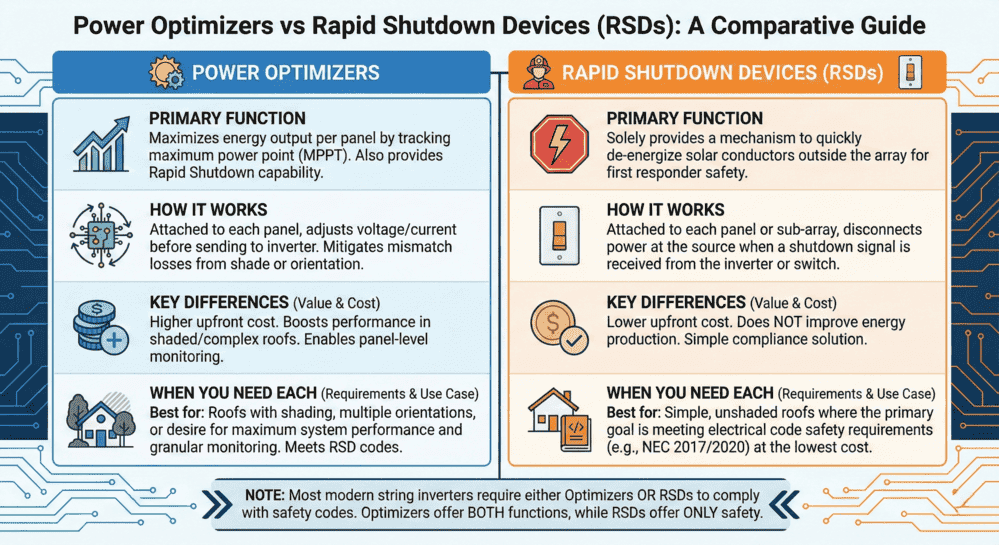

Inspect arrays throughout the day, especially during morning and late afternoon when shadows shift most. Nearby trees, roof features, or new construction commonly cause shading. Property owners should watch for new obstructions. Installing microinverters or power optimizers mitigates shading effects across arrays, especially in systems with variable light exposure. Professional shading analysis identifies problematic areas.

Solar Panel Microcracks

Microcracks, also called microfractures, rank among the most overlooked common solar panel defects. These tiny, often invisible cracks occur in silicon cells due to handling during shipping, installation stress, or thermal cycling over time. Left unchecked, microcracks spread, causing solar panel damage and long-term power loss.

Visual inspection under proper lighting may reveal faint lines, but electroluminescence (EL) testing provides the gold standard for detecting microcracks. When microcracks are found and panel output remains within acceptable limits, no action may be needed. However, significant cracking affecting energy production may warrant panel replacement or warranty claims.

Solar Panel Delamination

Solar panel delamination occurs when internal module layers, particularly between glass, encapsulant, and backsheet, begin separating. This separation allows moisture and air infiltration into panels, leading to busbar corrosion, solar panel discoloration, and eventual electrical failure.

To identify delamination, perform close visual inspections for bubbling, blistering, or layer separation. EL imaging also detects underlying defects not visible to eyes. Severe solar panel delamination not only reduces efficiency but poses safety risks due to electrical shock potential. When panels remain under warranty, contact manufacturers for replacement options. For aging systems with widespread delamination, decommissioning may prove more cost-effective than replacing individual panels.

Potential Induced Degradation (PID)

PID represents a well-documented and common solar panel defect that significantly reduces PV system performance and reliability. PID occurs when high-voltage potential differences exist between photovoltaic cells and frames, glass, or mounting structures. This mismatch allows leakage currents to flow, degrading solar cells and causing energy production drops. PID proves particularly problematic in hot and humid environments and represents a leading cause of long-term solar panel damage.

To detect PID, system owners and operators should routinely monitor output levels and compare actual performance against modeled expectations. Sudden or gradual production declines, especially under high temperature and humidity conditions, can signal PID onset. Left unaddressed, PID causes significant system output losses and contributes to other solar panel defects like solar panel discoloration and premature module aging.

Addressing PID involves both preventive and corrective strategies. PID reversal devices can sometimes restore lost performance in affected panels. Proper system grounding and insulation minimize voltage leakage and reduce PID risk. Additionally, using string inverters with transformer isolation or module-level power electronics (MLPE) like optimizers provides better voltage control and helps prevent this type of solar panel damage from developing.

Solar Panel Diode Failure

Solar panel diode failure represents a critical and often overlooked issue with major system performance impacts. Bypass diodes, built into panel junction boxes, redirect current around shaded or underperforming cells to prevent energy losses and protect systems from hotspots. When these diodes fail, typically by short-circuiting or becoming open, they result in severe efficiency drops, sometimes causing more than 33% power output reduction from affected panels. This failure also leads to overheating and visible solar panel discoloration, ultimately shortening panel lifespan.

According to recent PVEL PV Module Reliability Scorecards, solar panel diode failure remains among the top contributors to performance degradation across multiple module brands. To catch these issues early, solar professionals should regularly review system monitoring data for unusual production losses or thermal imbalances. Visual inspections also reveal common solar panel defects like burned junction boxes or localized hotspots, clear indicators of diode problems.

The only reliable fix for solar panel diode failure involves replacing faulty diodes, which often requires accessing or replacing entire junction boxes. Early intervention prevents cascading failures and reduces long-term solar panel damage or safety hazard likelihood. Regular maintenance, paired with performance analytics, ensures optimal energy yield and supports long-term solar PV system reliability.

Top Equipment Issues That Compromise Solar Performance

Several common solar panel defects significantly reduce system performance and reliability over time. One of the most frequent issues involves microcracks, tiny fractures in photovoltaic cells that often occur during manufacturing, handling, or transportation. These cracks spread over time, disrupt current flow, and contribute to uneven degradation or solar panel discoloration.

Another major issue involves solar panel delamination, where panel layers separate due to poor lamination or environmental exposure. Delamination allows moisture to enter modules, increasing solar panel damage risk, corrosion, and long-term output decline.

Hotspots also present critical concerns. These occur when panel sections overheat due to shading, cell mismatch, or manufacturing flaws. Hotspots not only reduce efficiency but also lead to physical damage such as cracked glass or burn marks. Finally, solar panel diode failure represents another important defect requiring attention. When bypass diodes malfunction, they prevent current from properly bypassing shaded or damaged cells, leading to significant power losses and increased hotspot risk.

Staying aware of these solar panel defects and addressing them through proactive maintenance and monitoring proves essential for maintaining long-term solar system performance.

Understanding Panel Color Changes: Key Factors And Environmental Triggers

Solar panel discoloration serves as a visible and often early indicator of solar panel defects or environmental degradation. It typically presents as yellowing, browning, or uneven shading across PV module surfaces and can be detected during routine visual inspections. While some discoloration may be cosmetic, many cases signal underlying issues that contribute to solar panel damage and reduced energy output. The following represent the most common causes of solar panel discoloration:

Exposure to UV Radiation: Prolonged ultraviolet (UV) ray exposure degrades encapsulant materials and polymers within panels, especially in lower-quality modules. This leads to solar panel discoloration such as yellowing or browning and often signals early-stage solar panel delamination or chemical breakdown inside module layers.

Environmental Pollution: Dust, pollen, industrial emissions, and airborne pollutants accumulate on panel surfaces over time. These substances form layers that not only cause visual discoloration but also block sunlight from reaching solar cells, contributing to long-term solar panel defects and decreased output when not regularly cleaned.

Moisture and Humidity: In high-humidity environments or regions with frequent rainfall and fog, moisture seeps into compromised panel edges or backsheets. This encourages mold, lichen, or algae growth, leading to both solar panel discoloration and potential solar panel damage due to electrical isolation breakdown or corrosion. Proper load analysis during installation prevents moisture accumulation.

Improper Maintenance: Lack of cleaning and preventive maintenance allows debris and biological growth to settle on panels for extended periods. This not only causes uneven discoloration but increases hotspot risk and degraded system performance, especially in systems with solar panel diode failure or poorly ventilated mounting designs.

Material Degradation: Over time, materials used in panel construction, particularly encapsulants, chemically degrade under heat, UV radiation, and environmental stress exposure. This often results in visible solar panel discoloration and may accompany solar panel delamination, reducing transparency and interfering with light transmission. Research shows climate change impacts degradation rates.

Professional Testing Equipment For Pinpointing Module Problems

Detecting common solar panel defects like discoloration, delamination, and solar panel diode failure often requires more than visual inspection. Many issues, such as microcracks, potential induced degradation (PID), or internal electrical faults, remain hidden without proper diagnostic tools. Solar professionals rely on various technologies, such as machine vision, to pinpoint root causes of solar panel damage and underperformance.

Common Diagnostic Tools Most Solar Installers Use

Multimeters and Clamp Meters

These essential electrical tools measure voltage and current at panel or string levels. Multimeters confirm whether panels generate power, while clamp meters measure current flowing through conductors. When panels show low or zero voltage, this may signal internal issues such as solar panel diode failure, disconnected wires, or short circuits. These tools prove crucial for everyday troubleshooting and on-site diagnostics. Proper conduit selection protects wiring integrity.

System Monitoring Software

Module-level monitoring from inverters helps flag underperforming panels or strings. Data reveals patterns consistent with solar panel damage, such as sudden output drops, irregular shading, or diode failure signs. Monitoring also detects emerging problems like solar panel discoloration or delamination, which may appear as gradual efficiency loss across specific modules.

Handheld IR Thermometers or Entry-Level Thermal Cameras

Some installers use affordable infrared tools to identify hotspots caused by solar panel diode failure, cracked cells, shading, or loose electrical connections. While not as detailed as professional-grade IR cameras, these tools detect elevated surface temperatures, an early indicator of hidden solar panel defects or damage.

Advanced Diagnostic Tools Used By Some Installers Or Specialists

Electroluminescence (EL) Testing

EL testing uses specialized cameras to capture near-infrared light emitted by solar cells when voltage is applied in darkness. This method reveals otherwise invisible microcracks, solar panel delamination, broken busbars, and encapsulant defects.

Best for: Identifying subtle structural damage resulting from manufacturing flaws, transportation stress, or poor installation.

Common defects detected: Microcracks, snail trails, inactive cells, and cell fractures.

Infrared (IR) Thermography

IR thermography uses thermal imaging to detect temperature differences across panel surfaces. Hotspots clearly indicate internal faults, typically linked to solar panel diode failure, corrosion, or shading. IR scans prove especially useful for large arrays.

Best for: Diagnosing overheating that causes solar panel discoloration, cracked glass, or fire risk.

Common defects detected: Diode failure, loose connections, moisture damage, and PID.

IV Curve Tracing

IV (current-voltage) curve tracers assess panel electrical performance under different loads. Deviations from expected curves reveal various issues, including bypass diode failure, PID, or mismatched modules in arrays.

Best for: Verifying system performance and isolating causes of underproduction.

Common defects detected: PID, low output, wiring errors, soiling, shading issues.

Choosing Reliable Panels: Quality Standards And Performance Testing

Choosing appropriate solar panels represents one of the best ways to avoid common solar panel defects like Potential Induced Degradation (PID), solar panel delamination, and diode failure. The PVEL 2024 scorecard provides a helpful resource for property owners, ranking PV modules based on extensive reliability and performance testing. Panels performing well in thermal cycling, humidity-freeze, and mechanical stress tests demonstrate greater resistance to solar panel damage and long-term performance loss. Professional residential solar design incorporates quality module selection.

By selecting high-quality modules from manufacturers with strong PVEL test results, property owners reduce chances of encountering common solar panel problems like solar panel discoloration or electrical failure. Investing in proven, durable equipment helps ensure systems deliver dependable energy output and savings for years. Commercial solar design requires even higher reliability standards.

Conclusion

Solar energy systems should consistently deliver reliable energy and long-term savings. When performance drops occur, underlying issues may exist, sometimes caused by common solar panel defects such as solar panel discoloration, delamination, or diode failure, which may receive coverage under manufacturer warranties. Understanding these issues helps property owners recognize signs of solar panel damage early and work with trusted providers to restore performance. Off-grid systems face unique defect challenges.

Effective system design proves key to preventing many common solar panel problems, including Potential Induced Degradation (PID) and solar panel diode failure. Features like proper grounding, adequate airflow, and high-quality materials help reduce overheating and electrical stress, improving durability and extending solar installation lifespan. Understanding liability risks protects against defect-related claims.

FAQs

Get answers to common questions about solar panel discoloration, delamination, diode failure, and more. Visit the Solar Permit Solutions blog for additional resources.

Do Defects Cause Solar Panel Discoloration?

Solar panel discoloration typically results from long-term elemental exposure, such as sunlight, rain, and dust. Additionally, uncontrolled chemical reactions between lamination materials, such as EVA (ethylene-vinyl acetate), and environmental oxygen contribute to discoloration. However, although solar panel discoloration may affect panel aesthetic appearance, it generally does not impact solar energy output or efficiency.

In some cases, severe discoloration potentially indicates damage, although discoloration presence does not necessarily imply a solar panel defect. The most common defects in solar panels include issues such as hot spots, snail trails, and material imperfections. These defects impact performance, longevity, and panel safety.

What Causes Solar Panel Diode Failure?

Solar panel diode failure may occur due to overheating in high temperatures, excess voltage from mismatched panels, reverse polarity from wiring issues, manufacturing defects, lightning strikes, moisture issues causing corrosion, and natural aging. These factors compromise solar panel diode integrity, decreasing solar system output. Regular monitoring and maintenance prove essential for detecting and addressing potential issues quickly.

How Can Solar Panel Diode Failure Be Prevented?

Preventing solar panel diode failure starts with proper installation and quality components. Using surge protection devices, regularly inspecting for solar panel damage, and keeping panels clean help reduce stress on bypass diodes. Minimizing shading through thoughtful panel placement also decreases hotspot risk that can trigger diode issues. Solar Permit Solutions provides expert installation guidance.

Effective sealing and temperature management prove key to avoiding moisture ingress, which leads to long-term solar panel defects like diode failure and discoloration. Choosing PV modules from reputable manufacturers known for quality and durability further protects against common solar panel problems, helping ensure system longevity and performance.

How Can Common Solar Panel Problems Be Detected?

Regular solar system monitoring and inspection prove essential for detecting common solar panel problems or defects. Visually inspect panels for physical damage, use monitoring software to track renewable energy production, and check inverter readings for abnormalities.

Solar technicians can analyze shading patterns and conduct electrical tests to identify wiring issues. Early detection and intervention of solar panel damage and issues help maintain optimal solar system performance.

What Is Solar Panel Delamination And How Serious Is It?

Solar panel delamination occurs when the internal layers of a module separate, typically between the glass, encapsulant, and backsheet. This separation allows moisture and air to penetrate the panel, leading to corrosion, electrical failures, and reduced efficiency. Delamination appears as bubbling, cloudiness, or blistering on the panel surface. This defect represents a serious issue that can compromise both system performance and safety. Panels showing signs of delamination should be evaluated by professionals, as severe cases may require replacement to prevent further damage and maintain optimal energy production. Contact professionals for assessment.