Solar panel structural requirements encompass load calculations, engineering standards compliance, and building code adherence to ensure safe, durable installations. Proper structural design must account for dead loads (panel and equipment weight of 30-50 pounds per panel), live loads (maintenance personnel and snow accumulation), wind forces, and seismic activity based on ASCE 7 standards and International Building Code (IBC) requirements.

Successful solar installations depend on three critical structural factors: roof integrity assessment (material type, age, slope, and load-bearing capacity), proper mounting system selection (aluminum or steel frameworks rated for environmental conditions), and regulatory compliance with local building codes and permitting requirements. Engineers must evaluate whether existing structures can support total system weight plus environmental forces, or if reinforcements are necessary before installation.

Structural failures in solar installations occur when load calculations are inadequate, mounting systems are improperly specified, or building codes are not followed. Wind uplift, snow accumulation, and seismic events can compromise poorly engineered systems, leading to property damage and safety hazards. Professional structural engineering ensures installations withstand environmental stresses while maintaining compliance with International Residential Code (IRC), International Building Code (IBC), and regional amendments for 25-30 year system lifespans.

Solar Permit Solutions provides comprehensive structural engineering and permitting support for residential, commercial, and ground-mounted solar projects. Professional expertise in load calculations, code compliance, and permit applications streamlines installation processes while ensuring structural integrity and regulatory adherence. Contact Solar Permit Solutions to discover how expert assistance eliminates structural planning complications and accelerates project approvals.

Core Principles Of Solar Panel Structural Design

Understanding Photovoltaic System Basics

Solar energy provides sustainable power generation while reducing fossil fuel dependency and utilizing abundant renewable resources. Photovoltaic panels convert sunlight into electricity and are typically installed on rooftops for residential, commercial, and industrial applications.

Successful installation extends beyond identifying available space. Systems must demonstrate safety, efficiency, and longevity. Structural integrity forms the foundation of reliable operation. The supporting structure serves as the backbone, and its strength determines system viability. Residential solar systems cannot achieve optimal performance without adequate structural support.

The Critical Role Of Roof Integrity In Solar Installations

Roofs perform critical functions in solar installations. The platform supports panel weight and maintains system stability. Before installation commences, several factors require thorough evaluation to ensure safe operation and prevent roof damage.

Roof material: Different roofing materials affect installation methods and load capacity. Common materials include asphalt shingles, metal roofing, and clay tiles. Each material type presents distinct characteristics influencing solar panel compatibility.

Roof age: The age of existing roofing significantly impacts installation feasibility. Older roofs may require reinforcement before supporting solar panels. Professional inspection determines whether repairs or replacement are necessary before proceeding.

Roof slope: Solar panels require optimal angles for maximum sunlight exposure. Proper positioning determines whether systems achieve peak performance or underperform. Angle optimization represents the difference between efficient energy production and suboptimal output.

Load-bearing capacity: Professional engineers must verify that roofs can support total system weight. This includes panels, mounting hardware, electrical components, and seasonal snow accumulation. Verification prevents structural failure.

Local building codes: Regional regulations often mandate specific structural requirements, setbacks, and permits for solar installations. Consulting local authorities and adhering to these guidelines during planning and implementation stages ensures compliance.

Beginning with foundational elements ensures long-term success. When the supporting structure lacks integrity, other system components cannot compensate. Installations may function initially but fail to maintain safe and stable operation over time. Roof composition, age, pitch, weight capacity, and local code requirements all influence whether installations proceed smoothly or develop problems later.

Understanding Weight Distribution And Force Management

Installing panels on existing buildings involves more than space allocation. Weight distribution and structural stress require careful analysis. For systems to endure and buildings to remain safe, all forces acting upon structures must be evaluated. This includes permanent panel weight, intermittent maintenance loads, wind pressure, snow accumulation, and seismic activity. Each load type presents unique challenges requiring assessment before installation begins.

Static Versus Dynamic Load Classifications

Calculating roof load capacity involves understanding two primary weight categories. Dead loads remain constant, including panels, mounting racks, and hardware. This weight persists continuously. Live loads fluctuate, such as snow accumulation following storms, wind pressure against surfaces, and personnel movement during installation or maintenance. These variable loads create additional structural stress. When roof capacity limits are exceeded, failures can occur rapidly.

Determining Wind Force Requirements

Wind forces significantly impact solar panel stability. On flat or low-slope roofs, panels act as sails, catching wind gusts with substantial force. Building height increases wind exposure risk. Engineers perform detailed calculations before installation, applying civil engineering standards, local wind data, and analyzing mounting configurations and edge placements. These calculations determine whether reinforcements or heavier mounting equipment are necessary to prevent system damage during storms.

Environmental And Seismic Force Considerations

Wind pressure represents only one challenge for solar installations. Snow accumulation adds considerable weight to panels. In regions experiencing harsh winters, weight accumulates rapidly with each storm. Installers may increase panel tilt angles to facilitate snow shedding or reinforce underlying structures to prevent buckling under pressure.

Seismic activity presents additional concerns. In earthquake-prone regions, panels must withstand sudden ground movement. Seismic loads shake entire systems, and without proper reinforcements, failure risk increases substantially. Engineers follow building codes to ensure designs can flex and maintain security during seismic events.

Comprehensive analysis of dead loads, live loads, wind pressure, snow accumulation, and seismic forces provides complete structural assessment. These factors determine whether systems operate safely for years or fail when weather conditions or ground movement occur.

Technical Standards And Engineering Guidelines

ASCE 7 Guidelines

Engineers commonly reference ASCE 7, published by the Society of Civil Engineers, when designing solar panel structures. This standard establishes requirements for accounting for wind, snow, and dead weight to ensure panels remain safe and functional over time. These guidelines integrate with local and international building codes, making compliance mandatory. Following ASCE 7 ensures designs withstand structural demands and pass inspections.

International Code Compliance

Solar panel installations must comply with established regulations, including the International Residential Code (IRC) and the International Building Code (IBC). These codes define building construction standards and safety requirements. Compliance ensures systems are properly engineered rather than inadequately assembled.

The Structural Engineers Association of California (SEAOC) provides specialized guidance for solar installations on low-slope roofs. This documentation addresses detailed design considerations for wind, snow, and environmental stresses affecting systems. These guidelines provide additional support ensuring solar arrays maintain structural integrity.

Component Selection And System Architecture

Selecting Optimal Attachment Hardware

Mounting systems provide the critical interface between panels and supporting structures. Material selection affects durability, cost, and installation complexity. Common materials include:

Aluminum: Lightweight and corrosion-resistant, aluminum mounting systems are popular for residential installations. They simplify handling and reduce structural load demands.

Steel: Offering superior strength, steel mounting systems suit commercial and industrial applications requiring enhanced load capacity. Proper coating prevents corrosion in various environmental conditions.

Stainless steel: For coastal or highly corrosive environments, stainless steel provides maximum durability despite higher costs.

Mounting system selection should consider project scale, environmental conditions, and budget constraints.

Waterproofing Strategies For Roof Integration

Roof penetrations for mounting hardware create potential leak points. Proper sealing and waterproofing techniques prevent water intrusion. Installation methods include:

Flashing: Metal flashing around mounting points diverts water away from penetrations.

Sealants: High-quality sealants fill gaps around fasteners and mounting points.

Non-penetrating systems: Ballasted mounting systems eliminate roof penetrations entirely, suitable for flat roofs with adequate load capacity.

Effective waterproofing extends roof lifespan and prevents interior water damage.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Terrestrial Installation Frameworks

Base Support Options For Ground Systems

Ground-mounted solar installations require foundations supporting panel weight and resisting environmental forces. Common foundation types include:

Concrete footings: Poured concrete provides stable support for heavy systems and challenging soil conditions.

Driven piles: Steel or aluminum piles driven into the ground offer cost-effective foundations for stable soil conditions.

Helical anchors: These screw-shaped anchors twist into the ground, providing secure foundations with minimal soil disturbance.

Foundation selection depends on soil composition, site slope, and local environmental conditions.

Property Evaluation And Geotechnical Analysis

Before designing ground-mounted systems, comprehensive site assessment and soil testing identify potential challenges. Soil bearing capacity, drainage characteristics, and seismic risk all influence foundation design. Geotechnical engineers perform soil tests to determine appropriate foundation types and depths.

Support Framework Options For Ground Installations

Ground-mounted systems utilize racking structures supporting multiple panels. These systems must resist wind uplift, accommodate thermal expansion, and facilitate proper drainage. Design considerations include:

Fixed-tilt racks: These stationary systems maintain constant angles optimized for seasonal energy production.

Adjustable-tilt racks: Manual adjustment capabilities allow seasonal angle optimization.

Tracking systems: Single-axis or dual-axis trackers follow the sun’s movement, maximizing energy capture throughout the day.

Racking system selection balances energy production goals with budget and maintenance considerations.

Project-Specific Design Requirements

Home-Based Rooftop Applications

Residential installations present unique challenges due to varied roof types, ages, and conditions. Typical considerations include:

Attic access: Adequate attic access facilitates roof structure inspection and reinforcement if needed.

Truss spacing: Understanding roof truss or rafter spacing ensures mounting points align with structural members.

Aesthetic concerns: Residential installations must balance performance with visual appeal to satisfy homeowners and homeowners’ associations.

Large-Scale Business Facility Implementations

Commercial and industrial solar projects involve larger scale and greater complexity. Key considerations include:

Structural capacity: Commercial buildings often feature different structural systems requiring specialized engineering analysis.

Roof access: Large commercial roofs require safe access for installation crews and ongoing maintenance.

Building use: Occupied buildings necessitate installation methods minimizing disruption to business operations.

Parking Shelter And Shade Structure Systems

Solar carports and canopies serve dual purposes: providing weather protection and generating electricity. These structures require:

Column placement: Strategic column positioning maximizes usable space beneath structures.

Height clearance: Adequate clearance accommodates various vehicle sizes.

Drainage design: Proper drainage prevents water accumulation on structures.

Approval Processes And Code Adherence

Navigating Regional Construction Regulations

Building codes vary significantly between jurisdictions. Some municipalities maintain simple permitting processes while others require extensive documentation. Understanding local requirements before beginning design work prevents delays and costly revisions.

Electrical Code Compliance

Solar installations must comply with electrical codes, including the National Electrical Code (NEC) in the United States. Compliance ensures safe electrical system design, proper grounding, and appropriate disconnect mechanisms.

Interconnection Requirements

Connecting solar systems to utility grids requires meeting utility interconnection standards. These standards address power quality, safety disconnects, and metering requirements. Utility interconnection processes vary by region and utility provider.

Permit Application Process

Permit applications typically require:

Structural calculations: Engineering calculations demonstrating structural adequacy.

Electrical plans: Single-line diagrams and electrical specifications.

Site plans: Property surveys showing system locations and setbacks.

Product specifications: Panel, inverter, and mounting system documentation.

Thorough permit application preparation accelerates approval processes and reduces revision cycles.

Performance Verification And System Durability

Installation Best Practices

Proper installation techniques ensure system longevity and performance. Best practices include:

Torque specifications: Following manufacturer torque specifications prevents under-tightening or over-tightening connections.

Wire management: Proper wire routing and securing prevents damage from wind and weather.

Grounding compliance: Correct grounding protects systems from lightning strikes and electrical faults.

Post-Installation Inspections

Professional inspections verify installation quality and code compliance. Inspections typically evaluate:

Structural connections: Verifying all mounting hardware is properly secured.

Electrical safety: Confirming proper wiring, grounding, and disconnect installation.

System functionality: Testing system operation and performance.

Maintenance Planning

Regular maintenance preserves system performance and identifies potential issues before they escalate. Maintenance activities include:

Panel cleaning: Removing dirt and debris maintains optimal energy production.

Connection inspections: Checking electrical and mechanical connections for looseness or corrosion.

Performance monitoring: Tracking energy production identifies underperforming components.

Innovative Developments And Industry Evolution

Advanced Mounting Systems

New mounting technologies simplify installation and improve performance. Innovations include:

Rapid attachment systems: Quick-connect mounting hardware reduces installation time.

Integrated flashing: Factory-integrated flashing improves waterproofing reliability.

Smart mounting systems: Sensors embedded in mounting hardware monitor structural loads and system performance.

Building-Integrated Photovoltaics (BIPV)

Building-integrated photovoltaics replace traditional building materials with solar energy generating components. BIPV applications include solar roof tiles, solar facades, and solar windows. These systems present unique structural considerations as they serve both architectural and energy generation functions.

Floating Solar Systems

Floating solar installations on reservoirs and water bodies represent growing market segments. These systems require specialized floating platforms and anchoring systems designed for aquatic environments. Structural considerations include wave action, water level fluctuations, and corrosion prevention.

Compliance Specifications For Solar Equipment

Why Standardization Matters In Solar Technology

Solar technology advances continuously with new components, systems, and innovations emerging regularly. Without standardized specifications, compatibility issues would create chaos. Panels would not interconnect properly, wiring would not align, and system integration would fail.

Standards provide guidance ensuring systems are safe, legal, and durable, not merely efficient. These specifications serve as guardrails preventing reliability failures. Without standards, dependability diminishes significantly.

Solar panel standards address detailed performance requirements, durability specifications, and system compatibility. They evaluate factors including:

- Mechanical and electrical properties

- Temperature and humidity tolerance

- Resistance to UV exposure

- Insulation and grounding requirements

Organizations like the International Electrotechnical Commission (IEC) and national standards bodies establish and update standards periodically. Adherence to these standards guarantees compliance with local regulations and international best practices.

Understanding these standards helps solar project developers avoid complications from component incompatibilities or building code violations. This knowledge ensures overall success and longevity of solar panel installations throughout the industry.

Conclusion

Successfully implementing solar panel systems demands thorough understanding of structural requirements, load calculations, and regulatory compliance. From rooftop installations to ground-mounted arrays, every project requires careful evaluation of dead loads, live loads, wind forces, snow accumulation, and seismic activity. Engineers rely on established standards like ASCE 7 and International Building Code requirements to ensure installations withstand environmental stresses while maintaining critical safety margins. Overlooking these structural fundamentals leads to system failures, property damage, and potential safety hazards.

Material selection, mounting system choices, and waterproofing techniques directly influence installation longevity and performance. Whether utilizing aluminum or steel mounting systems, proper anchoring methods and foundation planning protect investments against extreme weather and environmental conditions. Regulatory compliance cannot be an afterthought. Building codes, electrical standards, and interconnection requirements vary significantly between jurisdictions, making early engagement with local authorities essential for avoiding costly delays and ensuring legal compliance.

The solar industry continues advancing with innovative technologies and emerging applications. Staying informed about industry standards and engineering best practices positions professionals to deliver superior results across residential and commercial projects. Professional expertise, meticulous planning, and attention to structural detail transform solar installations into lasting investments in sustainable energy infrastructure that generate clean power safely and reliably for decades. For more guidance, explore our solar resources.

FAQs

Building code compliance typically involves adhering to the International Building Code (IBC), International Residential Code (IRC), and National Electrical Code (NEC). Requirements vary by jurisdiction, so checking with local building departments before proceeding is essential. Local authorities provide necessary forms and guidance for ensuring safety and legal compliance.

Panel angle considerations also influence design. Fixed-tilt systems maintain constant angles, while adjustable setups allow seasonal modifications. Tracking systems represent the most advanced option, automatically following the sun’s path to maximize energy capture. Configuration choices depend on goals such as cost savings, space optimization, or efficiency maximization.

Solar panels require spacing for air circulation preventing heat buildup. Water drainage prevents pooling. Tilt and spacing affect sunlight capture and system performance. Proper wiring ensures safety and reliable operation. Professional expertise ensures compliance with local regulations, attention to critical details, and long-term system durability.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Solar panel installations must comply with local building codes, electrical codes, and zoning regulations. Most jurisdictions require permits before installation begins. Common requirements include structural calculations, electrical plans, site plans, and product specifications.

Solar panels typically require mounting systems providing stable bases and structural support. These systems are constructed from aluminum or steel and installed on roofs, ground locations, or other sites. Mounting systems must withstand wind, snow, and seismic loads while allowing air circulation and water drainage.

Optimal solar configurations vary based on location, available space, and building type. For most residential applications, roof-mounted panels are preferred because they conserve yard space and integrate architecturally. For properties with substantial land area, such as commercial facilities or larger lots, ground-mounted systems offer advantages.

Every solar installation requires solid foundations securing system components. On rooftops, secure attachments using adhesive mounts or fasteners through roofing materials ensure stability. For ground-based systems, foundations may utilize concrete footings, metal piles driven into soil, or helical anchors twisted deep into the ground. Foundation selection depends on soil type, land slope, and overall site conditions.

Solar panels typically weigh 30 to 50 pounds each before adding mounting racks and additional equipment. Environmental forces including wind pressure, rain, snow accumulation, and seismic activity add stress to roofs or foundations. Solar projects must verify that underlying structures can handle these loads without future complications.

Calculating roof loads involves accounting for panel weight, mounting racks, hardware, and environmental forces such as wind, snow, and seismic activity. Structural engineers analyze roof capacity, perform calculations, and determine whether reinforcement is necessary. Engineers also verify compliance with local building codes to ensure safety and legality.

No minimum roof age exists for solar panel installation. However, newer roofs in better condition simplify installation processes. Solar panels last 25 to 30 years, so installing on roofs with at least 10 to 15 years of remaining service life makes sense. Otherwise, additional costs for panel removal and reinstallation may be incurred if roof replacement becomes necessary too soon.

Not all roofs can support solar panel weight without modifications. Some cases require additional structural support. Requirements depend on current roof strength, equipment weight, and local regulations. Structural engineers assess conditions and determine if reinforcements are needed to ensure safety and security after panel installation. Contact us for professional evaluation.

Solar panels require adequate spacing rather than crowded arrangements. Exact spacing depends on panel size, configuration, and mounting system type. Spacing allows air circulation preventing overheating, reduces shading, and facilitates cleaning and maintenance. Typically, roof panels require approximately one inch spacing, while ground-mounted systems often need several feet.

Solar panel installation resembles arranging outdoor furniture strategically. Structures must withstand wind and weather, provide proper spacing, and optimize solar exposure angles. Mounting structures must handle heavy rain, snow, and seismic activity.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

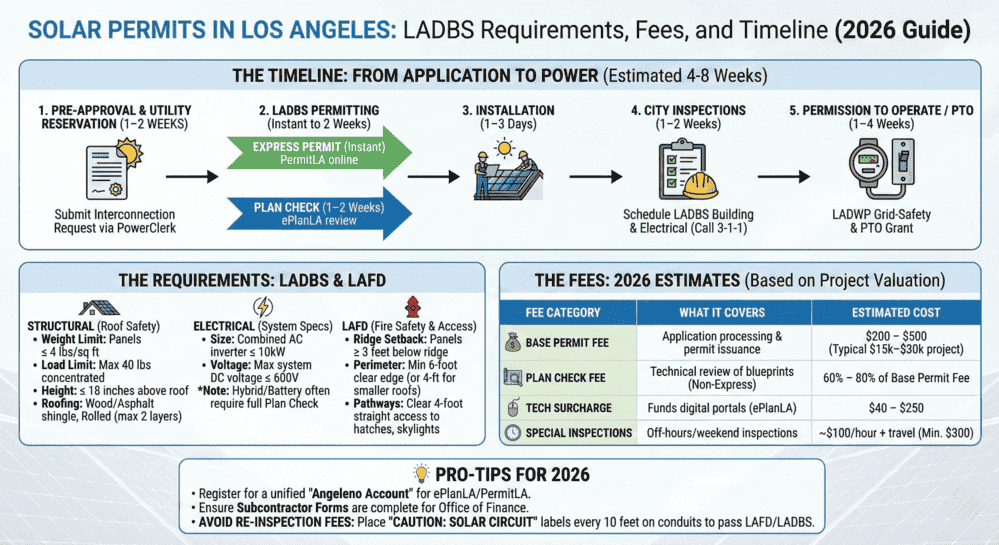

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...