Common DIY Solar Installation Mistakes

Installing solar panels yourself can save money, but cutting corners can lead to costly mistakes, failed inspections, and even safety hazards. Here are real examples from solar forums of DIY installations gone wrong — and how to avoid them.

Electrical Wiring Errors

One of the most common mistakes is improper wire sizing. Using undersized conductors can cause overheating, voltage drop, and fire hazards. Always follow NEC requirements for wire sizing based on your system amperage and run length.

Roof Penetration Issues

Improper roof attachments and flashing are a leading cause of leaks in DIY solar installations. Every roof penetration must be properly sealed and flashed according to manufacturer specifications.

Solar Permit Solutions

DIY Solar? We Handle the Permits.

You install the panels — we design the permit-ready plan set your building department requires. Fast, affordable, all 50 states.

Permit and Inspection Failures

Many DIY installers skip the permitting process entirely, which can result in fines, insurance issues, and problems when selling your home. Always obtain the required permits before installation.

The Professional Alternative

Working with a professional solar permit design service ensures your system meets all code requirements and passes inspection the first time. Contact Solar Permit Solutions for permit-ready plan sets.

DIY Solar? We Handle the Permits.

You install the panels — we design the permit-ready plan set your building department requires. Fast, affordable, all 50 states.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

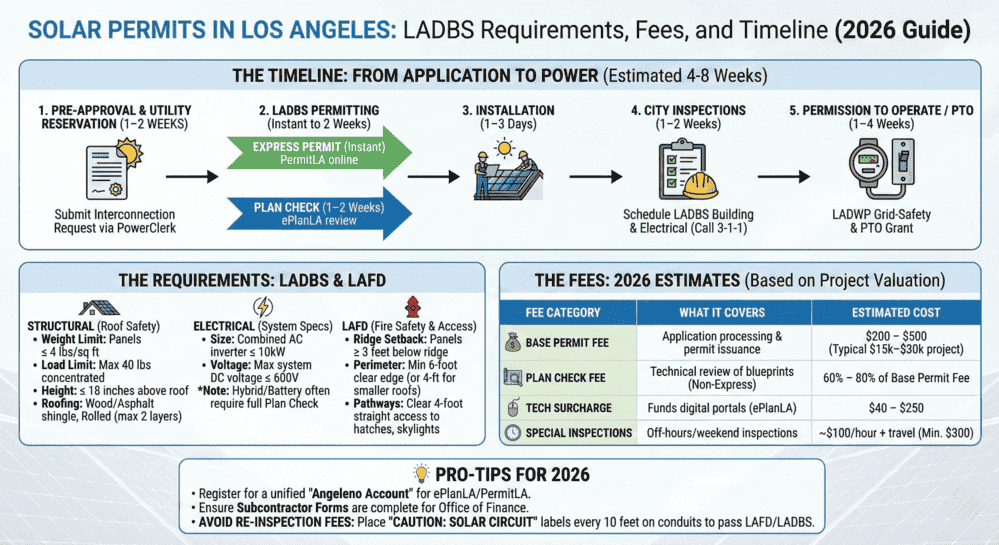

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...

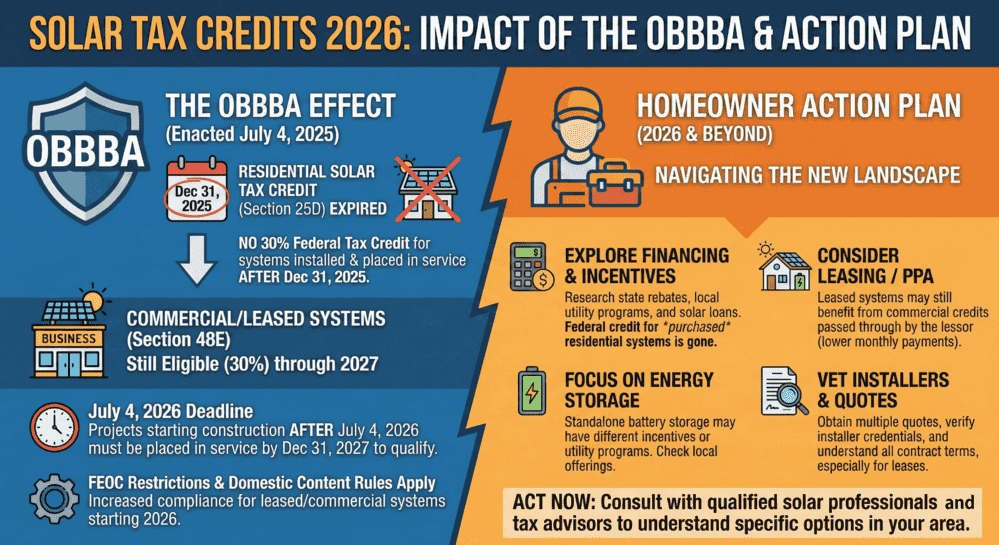

Solar Tax Credits 2026: What Changed After OBBBA and What Homeowners Can Do Now

Summary: The federal residential solar tax credit (Section 25D) expired December...