Understanding EG4 FlexBOSS21 Documentation For Permits

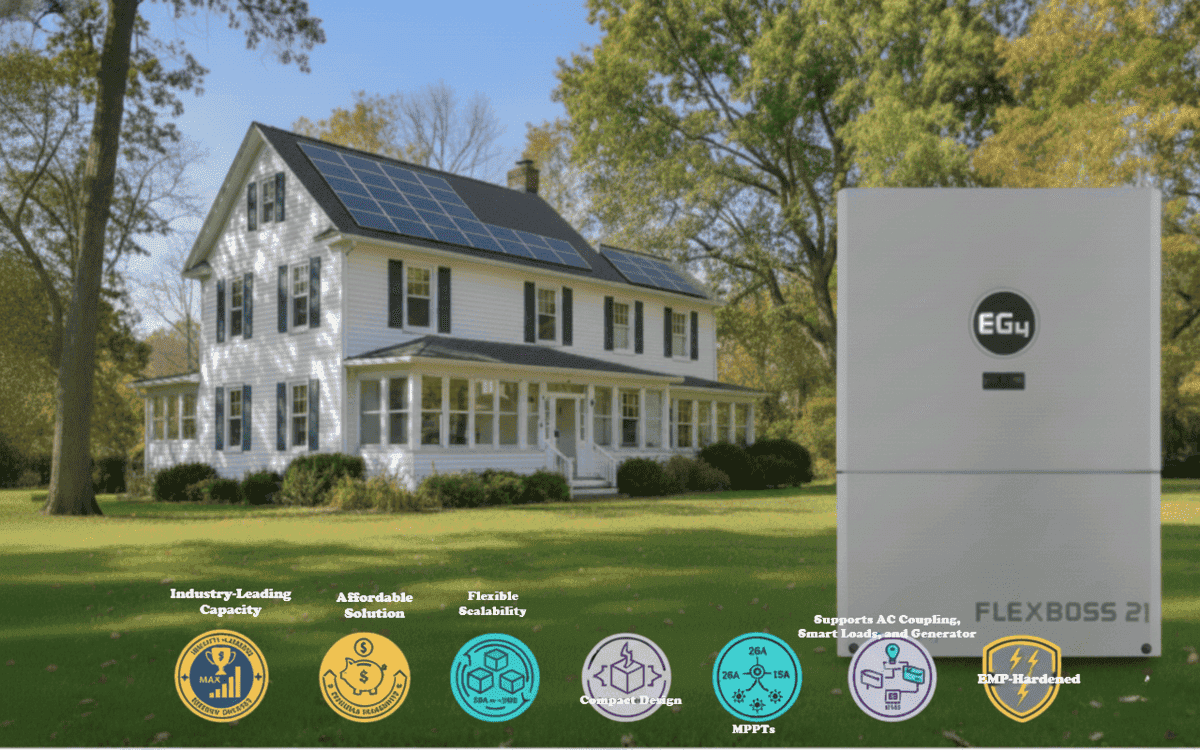

EG4 FlexBOSS21 solar permit applications require four essential documents: the manufacturer’s Quick Start Manual, the Owner’s Manual, complete one-line electrical diagrams, and comprehensive solar plan sets. The FlexBOSS21 is a 21 kW hybrid inverter (16 kW AC output, 12 kW backup) with three MPPT inputs (26 A/26 A/15 A) and UL 3141 and UL 1741 certifications required by all authorities having jurisdiction (AHJs).

These documents prove code compliance with National Electrical Code (NEC) Articles 690, 705, and 706. The Quick Start Manual contains installation specifications, including torque values, wire sizing, and mounting requirements. One-line diagrams must show the split-phase 120/240V configuration, 50-amp nominal output, 90-amp feed-through capacity, and all three MPPT string connections with proper overcurrent protection.

Permit approval timelines range from 2 to 10 weeks depending on jurisdiction, according to standardized solar permitting practices. Fast-growing states like Texas and Arizona process permits in 2 to 4 weeks, while California and New York require 6 to 10 weeks. Complete solar permit packages include battery integration specifications, structural calculations for the 88-pound unit, and utility interconnection applications demonstrating compliance with international renewable energy standards.

Understanding The EG4 FlexBOSS21 Quick Start Manual

The Quick Start Manual serves as the primary field installation reference for FlexBOSS21 systems, providing step-by-step procedures for physical mounting, electrical connections, and initial system commissioning. This document details critical specifications, including the unit’s 30.4 by 22.3 by 11.2 inch dimensions, 88-pound weight, and minimum clearance requirements of 12 inches on sides, 24 inches above, and 18 inches below for proper ventilation and service access.

Step-By-Step Installation Process

Step 1: Pre-Installation Inspection – Verify the unit weighs 88 pounds and measures 30.4 by 22.3 by 11.2 inches. Check for shipping damage, and confirm all accessories are present, including DC terminal covers, mounting brackets, and communication cables. Record the serial number from the rear panel label for warranty registration and technical support.

Step 2: Wall Mounting – Locate wall studs or install blocking capable of supporting 150 pounds. Use the mounting template to mark hole locations, ensuring the unit will be level. Maintain 12 inches clearance on both sides, 24 inches above, and 18 inches below. Install the mounting bracket with lag bolts penetrating at least 1.5 inches into solid wood, or use concrete anchors rated for 200 pounds pull-out strength on masonry walls.

Step 3: DC Input Wiring – Route PV conductors through conduit knockouts on top or sides of chassis. Connect strings to MPPT 1 (26A), MPPT 2 (26A), and MPPT 3 (15A) terminals. Use #10 AWG copper minimum for 13A panels. Verify polarity with a multimeter before tightening. Torque DC terminals to 7.4 to 8.9 Newton-meters (65 to 79 inch-pounds) using a calibrated torque wrench. Install DC terminal covers meeting UL requirements.

Step 4: Battery Integration – Connect battery positive and negative cables using #2/0 AWG or larger copper conductors rated for maximum discharge current. Wire the CAN bus communication cable with proper CAN-High, CAN-Low, and shield connections per the wiring diagram. Verify 48 VDC nominal battery voltage (42-58 VDC operating range) before making final connections. Install a battery circuit breaker or fuse rated for DC interrupting capacity.

Step 5: AC Output Connections – Connect Line 1, Line 2, neutral, and ground to AC output terminals using #6 AWG copper minimum (#4 AWG recommended for longer runs). Route AC conductors to the main service panel or sub-panel. Install an appropriately sized circuit breaker per NEC Article 705. Verify split-phase 120/240V configuration and proper grounding to the building electrode system per electrical code requirements.

Step 6: System Configuration – Apply power to the unit and navigate the LCD menu to configure battery type (LiFePO₄, NMC, or lead-acid), charging parameters (bulk voltage, float voltage, and temperature compensation), grid voltage settings (180-264 VAC range), and operating mode (grid-tied, off-grid, or hybrid). Connect to Wi-Fi or Ethernet for remote monitoring. Verify all settings match battery manufacturer specifications.

Step 7: Commissioning and Testing – Verify DC input voltage on each MPPT falls within the 200-550 VDC operating range. Test battery charging by monitoring charge current and voltage progression through bulk, absorption, and float stages. Simulate grid loss to verify anti-islanding protection disconnects within 2 seconds per UL 1741 requirements. Test backup power operation under load, confirming 12 kW continuous output capacity.

Technical Specifications For Permit Applications

| Specification | Value | Permit Requirement |

|---|---|---|

| Model Number | IV-16000-HYB-AW | Must appear on all plan sheets |

| PV Input Power | 21 kW usable (24 kW max) | Required for array sizing calculations |

| MPPT Configuration | 3 MPPTs: 26A/26A/15A | Shows string assignment capacity |

| DC Voltage Range | 200-550VDC (600VDC max) | Validates string voltage calculations |

| AC Output Power | 16 kW at 240V, 13.8 kW at 208V | Determines load capacity |

| Backup Power | 12 kW continuous without PV | Critical circuit sizing |

| Nominal Output Current | 50A | Wire and breaker sizing |

| Output Voltage | 120/240V or 120/208V split-phase | Panel compatibility verification |

| Feed-Through Capacity | 90A utility power | Total service calculation |

| Battery Voltage | 48VDC nominal (42-58VDC range) | Battery system compatibility |

| Max Charge Current | 190A (configurable) | Battery circuit protection sizing |

| Max Discharge Current | 250A | Battery conductor sizing |

| Dimensions | 30.4″ × 22.3″ × 11.2″ | Site plan and clearance verification |

| Weight | 88 lbs | Structural load calculation |

| Operating Temperature | 14-131°F (-10 to 55°C) | Installation location suitability |

| UL Certifications | UL 3141, UL 1741 | Required for all jurisdictions |

| Grid Support | IEEE 1547-2018 compliant | Utility interconnection approval |

| Arc-Fault Protection | NEC 690.11 compliant | Safety system verification |

| Anti-Islanding | Disconnect within 2 seconds | Grid safety requirement |

| Warranty Period | 10 years standard | Long-term support documentation |

Installation safety protocols detailed in the Quick Start Manual address arc-fault protection per NEC Article 690.11, ground-fault detection sensitivity at 1 ampere, and rapid shutdown requirements meeting NEC Article 690.12 specifications. These protective systems ensure safe operation under normal conditions and rapid disconnect during fault scenarios, essential requirements for federal tax credit eligibility and code compliance across all jurisdictions.

Owner’s Manual: Critical Information For Solar Plan Sets

The Owner’s Manual provides detailed electrical specifications required for accurate one-line diagram creation, including the complete AC output characteristics of 16 kW continuous at 240 V (13.8 kW at 208 V), 12 kW backup power without PV input, and surge capacity sufficient to start 5-ton air conditioning units. These specifications prove system adequacy for whole-home backup applications and demonstrate compliance with load-serving requirements.

Load calculation methodologies outlined in the Owner’s Manual help designers verify the FlexBOSS21 meets building electrical demands without overloading circuits or equipment. The document specifies that the 90-amp utility feed-through capacity allows significant grid power to pass through the inverter to building loads even when the inverter is not actively generating, effectively supporting up to 21.6kW (90 A times 240 V) when combining inverter output and grid power according to industry best practices.

Warranty documentation within the Owner’s Manual establishes the 10-year standard warranty period and outlines requirements for maintaining coverage, including proper installation by qualified personnel, adherence to torque specifications, and regular maintenance schedules. AHJs often require warranty documentation as evidence of manufacturer support and long-term system reliability, particularly for residential solar installations where homeowners depend on equipment longevity.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

How FlexBOSS21 Specs Impact Your One-Line Diagram

The FlexBOSS21’s 21 kW usable PV input capacity (24 kW maximum) represents the highest DC input rating in its class, allowing substantial solar array sizing for both residential and small commercial applications.

The three MPPT configuration rated at 26A, 26A, and 15A supports up to five PV strings across three different orientations, providing exceptional design flexibility for complex roof geometries where optimal single-orientation mounting is impossible.

One-line diagrams must accurately represent the split-phase 120/240V output configuration with a 50-amp nominal current rating and appropriate overcurrent protection devices sized per NEC Article 705 requirements.

The diagram should indicate both the 16 kW continuous output rating and the 12kW backup-only rating, clearly distinguishing between grid-tied operation with PV contribution and battery-only operation during utility outages.

Sample One-Line Diagram Configuration

UTILITY GRID (240V Split-Phase)

│

│ 200A Service

│

┌───────▼────────┐

│ 200A MAIN │

│ BREAKER │

│ SERVICE PANEL │

└───┬────────┬───┘

│ │

Line-Side │ │ Standard Branch

Connection │ │ Circuits to House

│ │

#3 AWG Cu │ └──► House Loads

(THHN/THWN) │

100A OCPD │

│

┌───────▼────────┐

│ GRID INPUT │ 90A Feed-Through

│ (Line-Side │ Capability

│ Connection) │

└───────┬────────┘

│

┌───────────▼────────────┐

│ │

│ EG4 FLEXBOSS21 │

│ IV-16000-HYB-AW │

│ │

│ 16kW Grid-Tied │

│ 12kW Backup │

│ UL 3141 / UL 1741 │

│ IEEE 1547-2018 │

│ │

└─┬─────────┬──────────┬─┘

│ │ │

┌───▼───┐ ┌───▼───┐ ┌───▼───┐

│ MPPT1 │ │ MPPT2 │ │ MPPT3 │

│ 26A │ │ 26A │ │ 15A │

│150-580V│ │150-580V│ │150-580V│

└───┬───┘ └───┬───┘ └───┬───┘

│ │ │

═══════════════════════════════════════════════════════════════════════════════

PV DC CIRCUITS

═══════════════════════════════════════════════════════════════════════════════

STRING 1 (South-Facing) ┌─────────────────┐

8 × 400W Panels in Series │ 20A DC Breaker │

Voc: 388V | Isc: 11.5A | Imp: 10.4A │ (PV Rated) │

Vmp: 308V (at STC) └────────┬────────┘

│

Wire: #10 AWG Cu (THHN/THWN, 90°C) │

Conduit: EMT or PVC Schedule 40 │

│

┌───────▼────────┐

│ MPPT 1 │

└────────────────┘

STRING 2 (South-Facing) ┌─────────────────┐

8 × 400W Panels in Series │ 20A DC Breaker │

Voc: 388V | Isc: 11.5A | Imp: 10.4A │ (PV Rated) │

Vmp: 308V (at STC) └────────┬────────┘

│

Wire: #10 AWG Cu (THHN/THWN, 90°C) │

Conduit: EMT or PVC Schedule 40 │

│

┌───────▼────────┐

│ MPPT 2 │

└────────────────┘

STRING 3 (West-Facing) ┌─────────────────┐

6 × 400W Panels in Series │ 20A DC Breaker │

Voc: 291V | Isc: 11.5A | Imp: 10.4A │ (PV Rated) │

Vmp: 231V (at STC) └────────┬────────┘

│

Wire: #10 AWG Cu (THHN/THWN, 90°C) │

Conduit: EMT or PVC Schedule 40 │

│

┌───────▼────────┐

│ MPPT 3 │

└────────────────┘

═══════════════════════════════════════════════════════════════════════════════

BATTERY DC CIRCUIT

═══════════════════════════════════════════════════════════════════════════════

┌────────────────────────────────────────┐

│ BATTERY ENERGY STORAGE SYSTEM │

│ LiFePO4 (Lithium Iron Phosphate) │

│ │

│ Nominal: 48VDC │

│ Capacity: 20kWh (usable) │

│ Operating Range: 42-58VDC │

│ Max Charge: 190A │

│ Max Discharge: 250A │

│ │

│ UL 1973 or UL 9540 Listed │

└────────────────┬───────────────────────┘

│

│ #2/0 AWG Cu (+/-)

│ (THHN/THWN, 90°C)

│

┌───────▼────────┐

│ 200A DC │

│ BREAKER │

│ (DC Rated) │

└───────┬────────┘

│

│ #10 AWG Cu EGC

│ CAN Bus Communication

│

┌───────▼─────────┐

│ FLEXBOSS21 │

│ BATTERY INPUT │

└─────────────────┘

═══════════════════════════════════════════════════════════════════════════════

AC OUTPUT CIRCUIT

═══════════════════════════════════════════════════════════════════════════════

┌─────────────────┐

│ FLEXBOSS21 │

│ AC OUTPUT │

│ 16kW Max │

│ 240V L1-L2 │

└────────┬────────┘

│

│ #6 AWG Cu (L1, L2, N)

│ #10 AWG Cu (Ground)

│ (THHN/THWN, 75°C)

│

┌───────▼────────┐

│ 60A BREAKER │

│ (2-Pole) │

└───────┬────────┘

│

┌───────▼───────────────────────────────┐

│ CRITICAL LOADS SUBPANEL │

│ (Backup Power During Outage) │

│ │

│ Max Load: 12kW @ 240V │

│ │

│ Connected Loads: │

│ • Refrigerator (20A) │

│ • Lighting Circuits (15A × 2) │

│ • HVAC System (50A, 5-ton) │

│ • Critical Outlets (20A × 2) │

│ • Medical Equipment (20A) │

│ │

└───────────────────────────────────────┘

═══════════════════════════════════════════════════════════════════════════════

GROUNDING & BONDING

═══════════════════════════════════════════════════════════════════════════════

FlexBOSS21 Equipment Ground ──┬── #10 AWG Cu

│

PV Array Equipment Ground ────┤

│

Battery System Ground ────────┤

│

├──► #6 AWG Cu to Main Panel

│ Ground Bar

│

└──► Grounding Electrode System

(Ground Rods, UFER, etc.)

═══════════════════════════════════════════════════════════════════════════════

🔆 PV Array Configuration

8.8kW

22 × 400W

3.2kW (8 panels series)

3.2kW (8 panels series)

2.4kW (6 panels series)

231-388V (Vmp: 231-308V)

⚡ Inverter Specifications

EG4 FlexBOSS21 (IV-16000-HYB-AW)

16kW continuous

12kW continuous

240V split-phase

90A (21.6kW)

UL 3141, UL 1741, IEEE 1547-2018

🔋 Battery System

LiFePO4 (Lithium Iron Phosphate)

20kWh usable

48VDC

42-58VDC

190A

250A

CAN bus protocol

🔌 Wire Sizing & Protection

#10 AWG Cu, 20A DC breakers

#2/0 AWG Cu, 200A DC breaker

#3 AWG Cu, 100A breaker

#6 AWG Cu, 60A breaker

#10 AWG Cu minimum

#6 AWG Cu to ground bar

📏 NEC Calculations

11.5A × 1.25 = 14.4A

#10 AWG (30A @ 90°C)

20A (next standard size)

250A × 1.25 = 312.5A

#2/0 AWG (195A @ 75°C)

50A × 1.2 = 60A breaker

✅ Code Compliance

Solar Photovoltaic Systems

Interconnected Power Sources

Energy Storage Systems

Conductors for General Wiring

Grid Interconnection

UL 3141, UL 1741, UL 1973

📝 Important Design Notes

- Line-Side Connection: Grid input uses line-side tap connection before main breaker, allowing 90A pass-through without service panel upgrade

- Wire Insulation: All conductors are copper THHN/THWN rated for 90°C in dry locations, 75°C in wet/damp locations per NEC 310.15

- PV String Protection: Each string has individual 20A DC-rated breaker sized at 125% of short-circuit current (11.5A × 1.25 = 14.4A)

- Battery Sizing: #2/0 AWG conductor rated for 195A at 75°C termination, accommodates 250A discharge × 1.25 = 312.5A requirement

- AC Output Protection: 60A breaker provides 120% protection per NEC 705.12(B)(2)(3)(c) for 50A nominal output

- Grounding: All metal enclosures, frames, and equipment bonded with #10 AWG minimum to main panel ground bar

- Rapid Shutdown: System includes rapid shutdown compliance per NEC 690.12 (integrated in FlexBOSS21)

- Arc-Fault Protection: DC arc-fault protection integrated in inverter per NEC 690.11

- Ground-Fault Protection: Integrated in inverter per UL 1741 requirements

- Conduit: All exposed outdoor wiring in EMT or PVC Schedule 40 conduit, sized per NEC 300.5 burial depth requirements