Solar installation revisions and change orders affect over 50% of contractors, with revision rates exceeding 25% per project. The seven primary causes are: (1) inaccurate roof measurements, (2) incomplete site context, (3) inadequate structural analysis, (4) missing electrical details, (5) remote-only shading assessment, (6) changing local regulations, and (7) lack of technology investment. Prevention requires precise measurement tools, thorough on-site surveys, digital documentation, and compliance with jurisdiction-specific requirements.

What Causes Solar Installation Revisions and How Much Do They Cost?

Solar installation revisions and change orders represent one of the most significant profit drains in the residential and commercial solar industry. When installation teams arrive on-site only to discover that measurements don’t match, permits need resubmission, or critical site details were missed, projects can incur costs ranging from $1,300 to over $3,000 per revision.

Key Statistics:

- More than 50% of solar contractors experience revision rates above 25%

- Average revision costs: $1,000 per module adjustment + $300-$1,000 in re-permitting fees

- Labor inefficiencies: $30-$100 per hour in crew downtime

- Satellite measurements can be inaccurate by 12+ inches

- On-site surveys reduce revision rates by up to 90%

Why Revisions Happen: The root causes stem from relying on outdated measurement methods (satellite imagery, manual measurements), skipping thorough structural and electrical assessments, using remote-only shading analysis, and failing to account for jurisdiction-specific permitting requirements.

The Solution: Implementing drone photogrammetry, digital field documentation, comprehensive on-site surveys covering both structural and electrical systems, and maintaining jurisdiction-specific permit templates eliminates the majority of preventable revisions while protecting profit margins and customer satisfaction.

This guide examines each of the seven most common revision causes in detail, providing actionable prevention strategies that solar installation companies can implement immediately to reduce delays, protect profitability, and improve operational efficiency.

Issue 1: Imprecise Roof Measurements

Experienced solar professionals understand how installation schedules can completely collapse due to incorrect roof measurements. Even minor measurement discrepancies of several inches can trigger substantial delays and generate expensive change orders.

Many installation companies continue using satellite imagery or manual measurement techniques for design planning and installation preparation. Unfortunately, these methods present significant accuracy limitations. Satellite-based measurements can deviate by a foot or more, while manual measurements consume considerable time and remain susceptible to human error.

The solution lies in advanced technology. Drone-based measurement systems combined with photogrammetry software deliver highly accurate, real-time measurements that eliminate estimation errors. This precise site data ensures residential solar designs align perfectly with actual conditions during installation.

Issue 2: Incomplete Site Context Information

Insufficient site context documentation creates serious fitment complications. Critical elements including trees, chimneys, and adjacent structures require precise documentation and consideration.

Many teams attempt to expedite project timelines through remote imagery analysis. However, remote assessment tools frequently overlook crucial details like small vent pipes, which can trigger significant problems:

- Re-permitting expenses approximately $1,000 per occurrence

- Installing fewer modules than initially planned and purchased

- Work stoppages while crews develop on-the-spot revision solutions, potentially costing thousands in labor expenses

- Negative customer feedback and reviews

This demonstrates why thorough on-site property inspections, both exterior and interior, represent a valuable time investment. Quality-focused contractors understand that comprehensive upfront assessments, combined with robust training protocols and appropriate technology, prevent these common solar permit mistakes downstream.

Issue 3: Inadequate On-Site Structural Assessment

Installation teams that encounter roof damage or potential system failures can trace these issues back to insufficient structural analysis during the survey phase.

While drones effectively capture roof measurements and identify obstructions, verifying structural integrity from inside the property remains crucial. Document all findings using mobile applications and digital checklists to ensure comprehensive data collection.

For a complete understanding of structural and roof condition, inspect:

- Attic spaces

- Load-bearing support beams

- Roofing material layers

After confirming the roof’s capacity to support a photovoltaic system, the next step involves documenting the property’s electrical infrastructure, which connects to the fourth common revision cause. Understanding solar panel tilt and structural load requirements is essential for proper system design.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Issue 4: Inadequate Electrical System Documentation

Thorough electrical analysis is fundamental to accurate solar installations. Incomplete documentation of existing electrical infrastructure can necessitate major design modifications, re-permitting processes, and installation day delays.

Prevention starts with leadership. Executive teams and operations managers must establish comprehensive standards and training programs ensuring field personnel can execute detailed on-site surveys, documenting meters, main breakers, and wiring conditions. Mastering electrical fundamentals upfront eliminates surprises and prevents costly change orders.

Best practice involves digitizing the data collection workflow. Centralizing this information in an accessible platform allows design teams to easily reference critical field data during system design development.

Design and engineering teams benefit significantly from this approach, and companies see measurable improvements in profitability. Executing work correctly initially costs less than repeating flawed processes. Additionally, proper electrical documentation helps prevent DC connector risks in PV systems.

Issue 5: Remote-Only Shading Assessment

Solar shading assessment technology has advanced considerably, yet one principle remains constant: on-site data provides superior accuracy compared to remote alternatives.

As sales-driven and remote-first operational models have gained popularity, remote shading methodologies have become widespread. Unfortunately, this data often contains outdated information and misses critical changes like new tree growth or structural additions. While remote shading offers certain advantages, its limitations can produce inaccurate production projections and high rejection rates from third-party financing partners.

Transitioning away from remote shading presents operational challenges, but alternatives exist. Capturing real-time on-site shade data and converting it into three-dimensional models ensures accurate shading analysis and vegetation modeling. This methodology optimizes panel placement and prevents overestimating system production capacity. Referencing solar radiation data for your region can also improve production estimates.

Issue 6: Evolving Local Regulatory Requirements

Solar installations require permits from local authorities, and navigating these jurisdictions demands a systematic approach.

Regional requirements vary significantly, making jurisdiction-specific templates essential. These templates should consistently include:

- Property overview documentation

- Electrical system information

- Array layout plans

- Required stamps and placards

- Jurisdiction or utility-specific requirements

Overlooking or misinterpreting local authority and utility requirements during plan set preparation and submission creates significant delays and re-permitting needs. Understanding what happens if you install without proper permits underscores the importance of staying current with local regulations and ensuring design compliance from project inception.

When outsourcing plan set creation to third-party design or engineering services, verify they understand each jurisdiction’s specific requirements, including fire setback regulations and voltage drop calculations. Professional commercial solar design services should always factor in these considerations. Resources like SolSmart’s permitting guidance and community planning toolkits provide valuable frameworks for compliance.

Issue 7: Operating Without Technology Investment

Some installers maintain that they can manage operations without software solutions, relying instead on basic tools and dedicated staff to complete all tasks without technology investment.

Adopting new technology presents challenges. The vendor evaluation process, solution selection, and company-wide implementation require both time and financial resources. Many installation companies question whether the upfront investment justifies the returns. However, calculating the true cost of manual, unstructured approaches often reveals expenses exceeding initial expectations, particularly since this methodology typically generates more change orders.

Regarding revisions, the cost of maintaining outdated processes substantially exceeds technology investment. Consider the financial impact of foregoing technological assistance for roof measurements or site analysis:

- Installing one fewer module – $1,000 in lost revenue

- Work stoppage for three installers while communicating changes to customers regarding revised production specifications – approximately $30 for 30 minutes at $10 per worker

- Permit resubmission fees – $300

This calculation excludes the impact of negative customer reviews. Customer complaints about last-minute changes, describing crews as “unprofessional” or claiming “they installed something different than what we agreed on in the proposal,” can cost future business opportunities, resulting in thousands of dollars in lost revenue. These issues directly impact solar system costs and project feasibility.

Implementing solutions like drone technology, photogrammetry software, and mobile field applications substantially improves data accuracy and project planning capabilities, reducing the likelihood of these additional expenses. These technologies ensure accuracy from project initiation, eliminating various pain points in the survey, design, and engineering phases that trigger permit denials due to design mistakes.

Integrating these tools throughout project workflows enables teams to capture precise roof measurements, accurate real-world site context, and comprehensive shading analysis. This approach produces smoother installations and improved customer satisfaction. Proper solar panel racking system selection and installation also depend on accurate initial data.

Conclusion

Solar installation revisions and change orders represent more than mere inconveniences, they directly impact your company’s profitability, operational efficiency, and customer satisfaction. Understanding and addressing these seven primary causes can transform your installation process from reactive to proactive, significantly reducing costly delays and protecting your profit margins.

The path to minimizing revisions begins with recognizing that accuracy and thoroughness during the initial stages pay dividends throughout the entire project lifecycle. Whether it’s investing in precise measurement technology, conducting comprehensive on-site surveys, or implementing digital documentation systems, each preventive measure contributes to smoother installations and more predictable outcomes.

While the upfront investment in proper technology, training, and processes may seem substantial, the alternative, dealing with constant revisions, re-permitting fees, labor inefficiencies, and dissatisfied customers, proves far more expensive in the long run. Companies that prioritize accuracy from the outset consistently outperform those relying on outdated manual methods and reactive problem-solving.

By implementing the strategies outlined in this guide, solar installation companies can dramatically reduce their revision rates, improve their bottom line, and build a reputation for reliability and professionalism that drives long-term business growth. According to the International Energy Agency’s renewable energy outlook, professional installation standards will become increasingly critical as the solar market continues its rapid expansion. Organizations like the EPA’s Green Power Markets and Penn State’s grid-scale solar development guidance emphasize the importance of proper planning and execution.

The choice is clear: invest in getting it right the first time, or continue paying the hidden costs of preventable errors. Solar Permit Solutions provides the expertise needed to navigate these challenges successfully, whether you’re working on off-grid solar system design or large-scale commercial projects. For additional insights on solar project optimization, visit the Department of Energy’s solar blog or explore global energy development resources, and check out our comprehensive blog resources.

Ready to reduce your revision rates and protect your profit margins? Contact our team today to discover how professional solar design and permitting services can transform your installation business.

FAQs

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

The cost of a single revision varies depending on the issue, but it can easily range from $1,300 to $3,000 or more per project. This includes expenses such as installing fewer modules (approximately $1,000), labor costs from work stoppages ($30-$100 per hour for crew downtime), and re-permitting fees (around $300-$1,000). Additionally, indirect costs like damaged customer relationships and negative reviews can result in thousands of dollars in lost future business.

Satellite imagery can be inaccurate by a foot or more, which is significant when designing solar installations where even a few inches matter. Drone-based photogrammetry provides real-time, highly accurate measurements that eliminate guesswork and ensure designs fit perfectly during installation. The precision difference between these two methods can mean the difference between a smooth installation and costly change orders.

While remote assessments may seem time-efficient initially, they frequently miss critical details like small vent pipes, new tree growth, updated structures, and accurate electrical configurations. These oversights lead to expensive revisions, re-permitting, and installation delays that far exceed the time saved. On-site surveys, especially when combined with digital documentation tools, provide comprehensive data that prevents costly surprises and ultimately saves both time and money across the entire project.

A thorough structural analysis should include inspection of the attic space, load-bearing support beams, and roofing material layers to verify the roof can support a photovoltaic system. Beyond the roof structure itself, you should also assess the home's electrical anatomy, including the condition of meters, main breakers, and wiring quality. Documenting all findings using digital checklists ensures no critical details are missed and provides your design team with the information needed to create accurate, permit-ready plans.

The most effective approach is creating jurisdiction-specific templates for each authority having jurisdiction (AHJ) you work with. These templates should include property overviews, electrical information, array plans, stamps and placards, and any AHJ or utility-specific requirements. Staying updated on local regulations through regular communication with permitting offices and ensuring your design team (whether in-house or outsourced) understands specific requirements like fire setbacks and voltage drop calculations is essential. Consider utilizing solar permit expediting services to streamline compliance across multiple jurisdictions. Maintaining organized, accessible documentation of each jurisdiction's unique rules prevents re-permitting delays and keeps projects on schedule.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

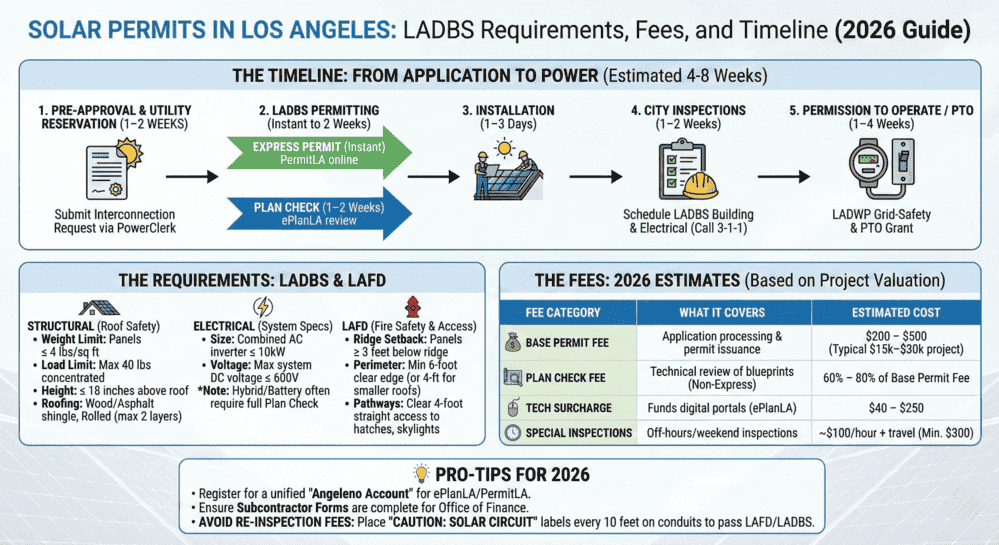

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...