When planning a solar installation, understanding the difference between rapid shutdown devices and power optimizers is crucial for building code compliance, safety, and system performance optimization. Both solutions address NEC Section 690.12 mandates, but they serve distinctly different purposes. While rapid shutdown devices focus solely on emergency de-energization, power optimizers combine safety compliance with performance enhancement. This guide explains the technical differences, cost considerations, and when each solution makes sense for your project.

Key Takeaways

- Rapid shutdown devices meet NEC 690.12 safety requirements only – no performance benefit

- Power optimizers include RSD functionality plus performance enhancement (5-25% energy gain)

- Cost difference: $25-35 per panel for standalone RSD vs $60-85 for optimizers

- ROI timeline for optimizers: 3-5 years on partially shaded or complex roofs

- UL 3741 offers alternative compliance for commercial projects without module-level devices

- All optimizers provide rapid shutdown, but not all rapid shutdown devices are optimizers

What is Rapid Shutdown and Why Is It Required?

Rapid shutdown is a safety mandate established by the National Electrical Code (NEC) to protect firefighters and emergency responders during building emergencies. When first responders need to access a roof with solar panels, they face potential electrocution hazards from energized DC conductors that remain live as long as sunlight hits the panels.

The National Electrical Code Article 690.12 addresses this risk by requiring rooftop solar installations to quickly de-energize to safe voltage levels when the system is shut down. This requirement has evolved through several NEC editions, with the current standards found in NEC 2023. The NEC 2026 edition was published in late 2025, but most jurisdictions continue enforcing the 2023 (or earlier) versions and will take 2-4 years to adopt the latest code.

Current NEC Rapid Shutdown Requirements

Under NEC 2023 Article 690, rooftop photovoltaic systems must meet these criteria:

Certification requirement: All rapid shutdown equipment must be UL listed

Conductors outside the array boundary: Must reduce to ≤30 volts within 30 seconds

Conductors inside the array boundary: Must reduce to ≤80 volts within 30 seconds

Array boundary definition: Area extending 1 foot from the array in all directions

Initiation methods: Manual switches, service disconnects, or automatic upon AC power loss

Systems Exempt from Rapid Shutdown

Not every solar installation requires rapid shutdown compliance:

- Ground-mounted solar arrays – firefighters don’t conduct operations on ground-level arrays (per NEC 2023 exemptions)

- Non-enclosed structures – carports, solar canopies, and trellises (per NEC 2023 Exception No. 2)

- Systems installed before local NEC adoption are typically grandfathered unless substantial modifications occur

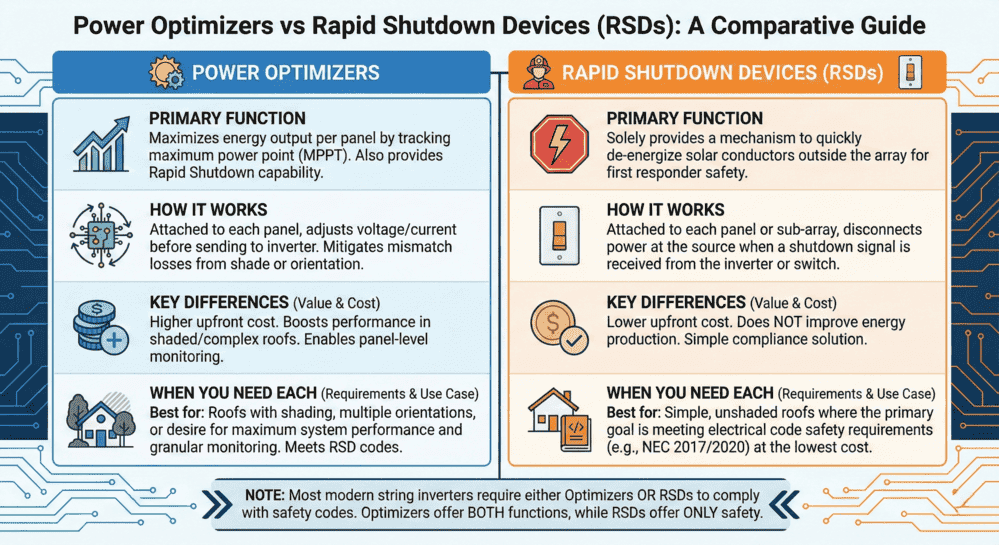

Power Optimizer vs Rapid Shutdown Device: The Core Difference - The primary difference between these technologies is intent and functionality. A rapid shutdown device is a safety-only component required by law to de-energize panels during emergencies. A power optimizer is a performance-enhancing MLPE device that includes rapid shutdown functionality but also maximizes energy yield by managing each panel’s output independently.

- Bottom Line: All power optimizers provide rapid shutdown compliance, but not all rapid shutdown devices are optimizers. The choice depends on whether you need just code compliance or both compliance and performance optimization.

Power Optimizer vs Rapid Shutdown Device: The Core Difference

The primary difference between these technologies is intent and functionality. A rapid shutdown device is a safety-only component required by law to de-energize panels during emergencies. A power optimizer is a performance-enhancing MLPE device that includes rapid shutdown functionality but also maximizes energy yield by managing each panel’s output independently.

Bottom Line: All power optimizers provide rapid shutdown compliance, but not all rapid shutdown devices are optimizers. The choice depends on whether you need just code compliance or both compliance and performance optimization.

How Rapid Shutdown Devices Work

Rapid shutdown devices function as an “emergency brake” for your solar array. These are passive safety components that monitor system status and respond when shutdown conditions occur.

Technical Operation

A module-level rapid shutdown device like the Tigo TS4-A-F Fire Safety unit or APsystems DS3 mounts behind each solar panel and connects inline with the DC wiring. The device continuously monitors for a “keep-alive” signal transmitted from the inverter through powerline communication or wireless protocols.

Under normal operating conditions, this signal tells the RSD units to maintain panel connectivity. When the signal stops due to AC power loss, emergency shutdown activation, or inverter disconnection, each RSD device physically disconnects its panel from the string circuit within seconds.

Voltage Reduction Process

The shutdown sequence works as follows:

- Trigger event occurs – AC breaker trips, emergency switch activated, or grid power lost

- Signal interruption detected – RSD devices recognize absence of keep-alive communication

- Isolation begins – Electronic switches open to disconnect each panel

- Voltage drops – System voltage falls below 80V inside array, below 30V outside array

- Safe state achieved – Complete within 30 seconds per NEC 2023 requirements

Performance Impact

Standalone rapid shutdown devices provide zero performance benefit during normal operation. They remain completely passive until a shutdown event occurs. Your panels produce the same amount of energy whether the RSD is present or not, because these devices don’t modify voltage, current, or power output under standard conditions.

Installation Considerations

RSD-only devices offer these characteristics:

- Simplicity – No configuration or commissioning required

- Compatibility – Work with any string inverter brand using compatible protocols

- Minimal failure points – Fewer electronic components than optimizers

- Lower upfront cost – Typically $25-35 per module installed

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

How Power Optimizers Work

Power optimizers function as active DC-to-DC converters that continuously adjust each panel’s electrical output while simultaneously providing rapid shutdown capability. Think of them as the “performance engine” that also happens to include safety features.

Technical Operation

Each optimizer performs Maximum Power Point Tracking (MPPT) at the module level. This means every panel operates at its optimal voltage and current regardless of what neighboring panels are doing.

In a traditional string inverter system without optimizers, all panels in a series string must operate at the same current. If one panel is shaded or underperforming, it limits the entire string’s output – known as the “Christmas light effect” where one bad bulb dims the whole strand.

Optimizers eliminate this constraint. Each device independently finds its panel’s maximum power point and converts the output to a voltage level compatible with the string requirements. The result is that shaded or soiled panels don’t drag down clean panels.

Optimization Functions

Modern power optimizers provide several active benefits:

Module-Level MPPT: Each optimizer tracks the maximum power point for its specific panel, compensating for:

- Partial shading from trees, chimneys, or roof features

- Panel mismatch from manufacturing tolerances or aging differences

- Soiling or debris on individual modules

- Temperature variations across the array

Panel-Level Monitoring: Optimizers report real-time performance data for each module, enabling:

- Identification of underperforming panels

- Detection of wiring or connection issues

- Tracking of degradation over time

- Immediate alerts for failures or problems

Rapid Shutdown Compliance: All optimizers include the same safety de-energization that standalone RSD devices provide, meeting all NEC 690.12 safety standards without additional components.

Performance Impact

The energy yield improvement from optimizers ranges from 5% to 25% depending on site conditions:

- Minimal shading, uniform orientation: 3-7% improvement from panel mismatch compensation

- Moderate shading or multiple roof planes: 10-15% improvement from shade mitigation

- Heavy shading or complex roofs: 15-25% improvement from individual panel optimization

These gains compound over the system’s 25-year lifespan. On a typical 10kW residential system, a 12% improvement translates to roughly 1,500 additional kWh annually, worth $150-300 per year depending on electricity rates.

Installation Considerations

Power optimizers require:

Monitoring platform subscription – Some manufacturers charge annual fees

Longer installation time – 45-60 seconds per module vs 30 seconds for RSD-only

System commissioning – Inverter must recognize and map each optimizer

Brand compatibility – Typically must match optimizer to inverter manufacturer

Higher upfront cost – $60-85 per module installed

Monitoring platform subscription – Some manufacturers charge annual fees.

Cost Comparison: Rapid Shutdown vs Power Optimizer

Understanding the total cost of ownership requires looking beyond initial equipment prices to consider performance gains, maintenance, and long-term value.

| Feature | Standalone RSD (Safety Only) | Power Optimizer (Safety + Performance) |

| Equipment Cost per Panel | $25 – $35 | $60 – $85 |

| Installation Time | 30 seconds/panel | 45-60 seconds/panel |

| Labor Cost Impact | Baseline | +15-20% higher |

| NEC 690.12 Compliance | Yes (UL listed) | Yes (UL listed) |

| UL 3741 Compatible | Yes | Yes |

| Shading Loss Recovery | 0% | 5-25% depending on conditions |

| Panel Mismatch Compensation | No | Yes |

| Module-Level MPPT | No | Yes (99.5% efficiency) |

| Individual Panel Monitoring | No | Yes (real-time data) |

| Performance Diagnostics | System-level only | Module-level alerts |

| Fault Detection | System-level only | Panel-level identification |

| Expected Lifespan | 10-15 years typical | 25 years (matches panel warranty) |

| Warranty Coverage | 10-12 years standard | 25 years standard |

| Best Applications | Unshaded ground mounts, budget projects, simple roofs | Residential rooftops, shaded sites, complex arrays |

| Typical ROI Period | N/A (code requirement) | 3-5 years on suitable sites |

| Compatible Inverters | Most string inverters | Brand-specific typically |

Total System Cost Example

For a typical 10kW residential system (28 panels):

Standalone RSD Configuration:

- Equipment: 28 × $30 = $840

- Installation labor: 28 × 1 min = 28 minutes

- Total added cost: ~$950-1,200

Power Optimizer Configuration:

- Equipment: 28 × $70 = $1,960

- Installation labor: 28 × 1.5 min = 42 minutes

- Total added cost: ~$2,100-2,500

Net difference: $1,150-1,300 additional investment for optimizers

Performance payback: If the site has moderate shading yielding 12% improvement on 12,000 kWh annual production, that’s 1,440 additional kWh worth $180-360 annually. ROI achieved in 3.2-7.2 years depending on electricity rates.

When to Choose Rapid Shutdown Only

Standalone rapid shutdown devices make financial and technical sense in these scenarios:

Ideal Site Conditions

Unshaded arrays with optimal orientation – If your roof faces directly south (or north in Southern Hemisphere) with zero shade throughout the day, optimizers won’t recover enough additional energy to justify their cost. The 3-7% gain from panel mismatch alone takes 10+ years to pay back the additional investment.

Ground-mounted systems – While technically exempt from rapid shutdown requirements in many jurisdictions, many installers include RSD for safety. Ground mounts typically have uniform exposure and orientation, minimizing optimizer benefits.

Budget-constrained projects – When capital is limited and the site doesn’t have significant shading, meeting code with minimum investment is reasonable. You can potentially add optimizers later if conditions change (trees grow, adjacent construction occurs).

Large commercial solar arrays – On massive installations with hundreds of panels, the optimizer cost differential becomes substantial. If the array has uniform exposure, standalone RSD or UL 3741-certified systems offer better economics.

Technical Scenarios

String inverter systems requiring basic compliance – Older inverter models may not communicate well with certain optimizer brands. Standalone RSD devices using powerline communication offer universal compatibility.

Utility-scale projects – Large ground-mount installations typically don’t require rapid shutdown and use central inverters optimized for cost per watt rather than module-level optimization.

Temporary or portable installations – Events, construction sites, or disaster relief applications where the array lifespan is under 5 years don’t justify optimizer investment.

When to Choose Power Optimizers

Power optimizers deliver compelling value in situations where their performance benefits exceed the additional cost.

Ideal Site Conditions

Partially shaded roofs – Any array with shade from trees, chimneys, vents, satellite dishes, or adjacent buildings benefits significantly from module-level optimization. Even 2-3 hours of partial shade daily can reduce string inverter output by 20-40%, while optimizers limit losses to only the affected panels.

Complex roof layouts – Residential installations spread across multiple roof planes with different orientations (east/west splits, dormers, multiple pitches) suffer from panel mismatch in string systems. Optimizers allow each plane to operate independently at its optimal point.

High monitoring requirements – Property managers, commercial building owners, and homeowners who want detailed performance visibility benefit from panel-level data. This enables proactive maintenance and quick identification of issues like damaged panels or connection failures.

Premium installations – High-value properties where maximum energy production justifies higher investment, or where clients specifically want the most advanced technology available.

Technical Scenarios

Panel mismatch situations – Arrays using panels from multiple manufacturers, different wattage ratings, or panels with varying ages benefit from individual MPPT. Common in expansion projects where matching original panels isn’t possible.

Extreme temperature differentials – Roofs with some panels in constant sun and others frequently shaded experience temperature variations that affect output. Optimizers compensate for temperature-induced voltage differences.

Dense urban environments – City installations face shade from surrounding buildings that changes throughout the day and seasons. The optimization benefits in these scenarios often exceed 20%.

Monitoring and diagnostics priority – Solar professionals, engineering firms, or technology enthusiasts who value detailed system analytics and want granular performance data for each module.

UL 3741 Alternative: Array-Level Compliance

An important compliance pathway gaining adoption is UL 3741, which establishes standards for Photovoltaic Hazard Control Systems. This approach represents a significant shift in how rapid shutdown requirements can be met.

How UL 3741 Systems Work

Rather than installing electronic devices on every panel, UL 3741-listed systems use engineered combinations of specialized racking, inverters, and array design to control electrical hazards through mechanical protection and controlled circuit architecture.

The UL 3741 standard, published in December 2020 and first referenced in NEC 2020, ensures that even if firefighters interact with the array during an emergency, the risk of dangerous shock is mitigated through:

- Insulated racking systems that prevent conductor exposure

- Controlled circuit designs that limit accessible voltage

- Specialized inverters with integrated hazard control features

- Physical barriers preventing contact with energized components

Benefits of UL 3741 Systems

Reduced Balance of System costs – Eliminating hundreds of individual module-level devices reduces material costs by 10-15% on large commercial projects.

Fewer electronic failure points – Module-level electronics exposed to extreme rooftop temperatures have finite lifespans. Array-level approaches reduce long-term maintenance concerns.

Simplified installation – Without devices on every panel, installation proceeds faster and with less complexity.

Scalability – Large commercial and utility-scale projects benefit most from streamlined approaches that meet safety requirements without individual panel electronics.

Limitations of UL 3741

Limited manufacturer options – Not all inverter and racking manufacturers offer UL 3741-certified systems, restricting equipment choices.

Residential availability – Most UL 3741 solutions target commercial and utility-scale markets, with limited residential options.

No performance optimization – These systems provide safety compliance only, with none of the energy yield benefits that optimizers deliver.

Certification complexity – The entire system must be installed exactly per UL listing requirements, reducing field flexibility.

When to Consider UL 3741

This approach works best for:

- Large commercial rooftop installations (100kW+)

- Projects where budget constraints prohibit optimizer investment

- Arrays with minimal shading where optimization benefits are limited

- Clients prioritizing long-term reliability over maximum energy production

Making the Right Choice for Your Solar Installation

Selecting between rapid shutdown devices and power optimizers requires evaluating your specific situation against these decision factors.

Decision Framework

Step 1: Assess your site conditions

- Is there any shading at any time of day or year?

- Does the array span multiple roof planes or orientations?

- Are all panels identical models and age?

Step 2: Calculate performance improvement potential

- Minimal shade, single orientation: 3-7% improvement with optimizers

- Moderate shade or split orientations: 10-15% improvement

- Heavy shade or complex layout: 15-25% improvement

Step 3: Run the financial analysis

- Additional optimizer cost for your system size

- Annual energy improvement value at your electricity rate

- Calculate simple payback period (should be under 7 years for good ROI)

Step 4: Consider monitoring requirements

- Do you want panel-level performance visibility?

- Is proactive maintenance detection important?

- Will you actively use monitoring data?

Step 5: Evaluate budget constraints

- Can you afford the 20-30% additional cost for optimizers?

- Does your financing include performance-enhancing equipment?

- Are there incentives or rebates specific to MLPE systems?

Quick Decision Guide

Choose standalone rapid shutdown if:

- Your roof has zero shading throughout the year

- All panels face the same direction with identical tilt

- Budget is the primary constraint

- You’re satisfied with system-level monitoring only

- The array is ground-mounted (where allowed without RSD)

Choose power optimizers if:

- Any shading exists at any time

- Multiple roof planes or orientations

- You want maximum energy production

- Panel-level monitoring is valuable to you

- ROI analysis shows payback under 7 years

- You’re willing to invest for long-term performance

Consider UL 3741 systems if:

- Large commercial installation (100kW+)

- Minimal shading conditions

- Budget prioritizes lowest installed cost

- Long-term electronic reliability is a concern

- Your inverter and racking manufacturers offer certified systems

Conclusion

The choice between standalone rapid shutdown devices and power optimizers ultimately comes down to balancing code compliance and permitting, site conditions, budget, and performance expectations.

If your installation faces a tight budget with an unshaded, south-facing roof, standalone RSD devices provide the most economical path to meeting NEC 690.12 electrical code requirements. You’ll achieve full code compliance while minimizing equipment costs, making this the right choice for straightforward installations prioritizing initial affordability.

If your roof experiences any shading, spans multiple orientations, or if you value detailed system monitoring, power optimization technology delivers compelling long-term value. The additional upfront investment typically pays for itself within 3-5 years through increased energy production, while providing 25 years of enhanced performance and diagnostics. For residential and commercial installations, optimizers represent the best total cost of ownership.

For large commercial projects with minimal shading, UL 3741 PV hazard control systems offer a third pathway that reduces balance of system costs while maintaining safety compliance without module-level electronics.

Whichever solution you choose, ensure all equipment carries proper UL listings, comes from established manufacturers with solid warranty programs, and matches your inverter brand’s compatibility requirements. Rapid shutdown is a safety-critical function – reliability and proper system integration matter more than minor cost differences.

Work with experienced solar installation professionals who can perform accurate shade analysis, calculate realistic ROI projections for your specific site conditions, and design systems that balance safety requirements with performance optimization for your individual needs. For professional solar permit design services, expert assistance is available to ensure your project meets all code requirements and maximizes performance.

Related Resources:

- NEC Rapid Shutdown Requirements – Electrical License Renewal

- UL 3741 Standard for Photovoltaic Hazard Control

- SolarEdge Power Optimizer Product Line

- Enphase Microinverter Systems

- Tigo Energy Module-Level Power Electronics

Frequently Asked Questions

How do I know which option is right for my roof?

Start with a shade analysis. If your roof experiences any shade at any time of day throughout the year, optimizers likely provide enough additional energy to justify their cost. Use this rough guide: completely unshaded south-facing roof = standalone RSD is fine; any other scenario = run the ROI calculation for optimizers. Most solar installers can provide shade analysis and expected performance improvements during the design phase.

What’s the difference between NEC 2017, 2020, 2023, and 2026?

The core rapid shutdown concept remains consistent across editions, but specific requirements have evolved. NEC 2017 Article 690 established the 30V/80V thresholds and module-level requirements. NEC 2020 introduced UL 3741 photovoltaic hazard control as an alternative pathway and refined initiation device rules. NEC 2023 added exemptions for carports, canopies, and solar trellises. NEC 2026 (published in late 2025) primarily reorganizes language for clarity without changing performance requirements. Most jurisdictions currently enforce the 2020 or 2023 editions, with 2026 adoption expected to roll out over the next 2-4 years.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

No. Microinverters from Enphase like IQ8 or APsystems handle both module-level optimization and rapid shutdown natively. Each microinverter converts DC to AC right at the panel, eliminating high-voltage DC wiring entirely. This inherently meets rapid shutdown requirements without any additional devices. You do not need separate RSD units or optimizers with microinverter systems.

Your solar system will continue producing power normally – the panels, inverter, and grid connection are unaffected. However, your installation is technically out of compliance because the safety function no longer works. Modern systems with monitoring capabilities can detect and alert you to RSD failures. During system inspections or if you sell the property, failed RSD devices must be replaced to pass. This is another reason why warranty coverage and product reliability matter significantly.

No. NEC Section 690.12 specifically applies to PV systems "on or in buildings." Ground-mounted arrays are explicitly exempt because firefighters do not conduct operations on ground-level installations. However, some jurisdictions or utilities may still require disconnect switches for ground mounts as a general safety practice, even though module-level rapid shutdown is not mandated.

No. Most optimizers are designed to work with specific inverter brands. SolarEdge power optimizers require SolarEdge inverters. Tigo MLPE products work with many inverter brands but require compatible communication. Some newer "universal" optimizers offer broader compatibility, but always verify specific inverter models are supported before designing your system. Enphase microinverter solutions avoid this issue entirely since they don't require a separate string inverter.

The core rapid shutdown concept remains consistent across editions, but specific requirements have evolved. NEC 2017 Article 690 established the 30V/80V thresholds and module-level requirements. NEC 2020 introduced UL 3741 photovoltaic hazard control as an alternative pathway and refined initiation device rules. NEC 2023 added exemptions for carports, canopies, and solar trellises. NEC 2026 (published in late 2025) primarily reorganizes language for clarity without changing performance requirements. Most jurisdictions currently enforce the 2020 or 2023 editions, with 2026 adoption expected to roll out over the next 2-4 years.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Your Complete DIY Solar Panel Installation Guide

Homeowners turn to solar energy for various motivations. Clean, renewable power ...

What Is A Commercial Solar PV System?

A commercial solar PV system is a renewable energy setup designed to help busine...

Complete Solar Panel Inspection Checklist: Protect Your Investment and Maximize Performance

A solar panel inspection checklist is a systematic tool for evaluating solar sys...