A solar panel inspection checklist is a systematic tool for evaluating solar system performance, safety, and compliance. Regular inspections prevent energy losses, identify equipment failures, and significantly extend system lifespan through early problem detection.

Why Solar Panel Inspections Are Critical

Solar panel systems require annual inspections at minimum to maintain optimal performance and safety. Professional residential solar design incorporates maintenance planning from the start. Without regular inspections, systems experience:

- Performance decline from undetected issues like soiling, shading, and component degradation

- Safety hazards including fire risks from loose electrical connections

- Warranty voidance when maintenance requirements aren’t met

- Code violations resulting in fines and legal complications

- Shortened equipment lifespan due to preventable component failures

What a Complete Solar Inspection Checklist Includes

A comprehensive solar panel inspection checklist covers seven essential areas:

- Visual Panel Assessment: Surface damage, cracks, soiling, and shading issues

- Structural Integrity: Mounting hardware, frame condition, and roof attachment points

- Electrical Connections: Wiring condition, combiner boxes, disconnect switches, and proper conductor sizing

- Inverter Performance: Output readings, error codes, breaker ratings, and rapid shutdown functionality

- Fire Safety Compliance: Connection tightness, insulation integrity, and circuit breaker specifications

- Documentation Review: Labeling accuracy, NEC standards compliance, and permit verification

- Performance Metrics: Energy output comparison, efficiency measurements, and monitoring system data

Inspection Frequency Recommendations

- Standard climates: Annual inspections (once per year)

- Harsh climates: Biannual inspections (twice per year for areas with extreme weather, heavy snow, or high heat)

- Commercial systems: Quarterly monitoring with annual professional inspection

For larger installations, commercial solar design services include maintenance planning.

- Post-storm or severe weather: Immediate inspection recommended

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Who Should Perform Solar Inspections

Professional solar inspections require certified inspectors with specific qualifications:

- NABCEP certification (North American Board of Certified Energy Practitioners)

- NEC standards expertise and local electrical code knowledge

- Experience with solar-specific equipment: Inverters, combiners, disconnect systems

- Specialized testing equipment: Irradiance meters, thermal cameras, IV curve testing tools

The EPA provides comprehensive solar installation guidance for best practices.

Property owners can perform basic visual checks between professional inspections, monitoring for obvious issues like panel soiling, shading changes, or performance drops visible through monitoring systems.

Preparing for a Professional Solar Inspection

Why Solar Inspections Matter for System Longevity

Inspections serve as an early warning system for solar installations. They identify critical issues before they become expensive problems. That unexpected productivity drop? A cracked panel might be the culprit. Loose wiring could create dangerous conditions. Solar panel inspections catch these issues early, keeping panels operating efficiently and protecting the initial investment.

Compliance matters significantly. Permits, approvals, and documentation stamped by the Authority Having Jurisdiction (AHJ) prevent fines, violations, and lengthy delays. Understanding permit requirements ensures smooth inspections. Local codes and national standards exist for specific safety and performance reasons, and inspectors verify that systems meet all requirements.

Comprehensive inspections examine both operational performance and regulatory compliance. One maintains energy production, the other ensures legal standing. The inspector verifies system conductors are properly sized and that correct breaker size is installed for safe operation.

Essential Pre-Inspection Checklist Items

Before beginning the solar panel inspection, prepare these essential items:

Documentation: Gather all necessary paperwork, permits, and approvals from the AHJ and the solar installation company. Ensure solar-specific code requirements appear in all documentation.

Site Plan: Review the site plan showing solar panel placement and potential hazards. Verify proper system disconnecting points and confirm listed equipment is clearly marked on the plan.

Safety Equipment: Secure appropriate personal protective equipment (PPE) for the inspection, including gloves, safety goggles, and hard hats. Safety remains paramount when working on solar systems.

Visual Inspection: Conduct a preliminary visual check for obvious problems such as damaged wiring or obstructed panels. Check inverter output levels and look for signs requiring immediate attention. Reference the DOE solar inspection checklist for comprehensive guidelines.

Hiring Certified Solar Inspection Professionals

Homeowners can perform basic inspections, checking for panel dust or examining visible wiring. However, complex technical inspections require professional expertise. Follow DIY safety guidelines when performing basic checks. A qualified inspector understands proper panel examination procedures and can identify solar panel system issues before they escalate into major problems.

Hiring qualified professionals ensures work complies with all regulations, codes, and signage requirements. This step protects warranties and the system’s future performance.

Skipping professional inspection might save money initially but can result in safety issues, performance problems, and warranty coverage loss later. Professionals ensure installations remain legal, safe, and fully functional. They understand NEC standards and can perform proper system inspections covering everything from roof mounting to electrical connections.

Comprehensive Solar System Component Evaluation

Performing Thorough Visual Panel Assessments

Thorough visual inspections prove essential for catching problems before they worsen. Begin by examining panel surfaces for cracks, debris, or dirt accumulation. Even minor soiling can block light and reduce efficiency. Each solar panel should remain clean and debris-free for optimal performance.

Shade assessment remains equally important. Overhanging branches, new growth, or small obstructions slow panel performance. When cleaning becomes necessary, follow manufacturer guidelines strictly. Improper cleaning methods can cause more harm than good.

Routine care and vigilant monitoring keep systems operating efficiently. Regular panel inspection catches small issues before they affect the entire array.

Verifying Structural Components and Mounting Systems

Solar panel construction and mounting systems critically impact performance and longevity. Inspect panel frames, rails, and mounting brackets for rust or damage. Proper structural engineering calculations ensure mounting integrity. Verify tight fastening, particularly for aluminum components that may degrade over time.

The roof structure should remain sound and capable of supporting solar system weight, especially in areas experiencing high wind or snow loads.

Proper grounding protects the solar installation from electrical surges. Correct grounding safeguards against lightning strikes and ensures safe operation of all listed equipment in the system.

Inspecting Electrical Wiring and Connection Points

Inspect all electrical connections for wear, damage, or loose fittings. These connections link panels, combiner boxes, DC and AC disconnects. Look for frayed or damaged wires that could create fire hazards or slow system performance.

System conductors must be properly sized and insulated to handle current loads from the solar panel array. Review wire sizing guidelines for proper conductor selection.

Verify wiring in combiner boxes matches labels to confirm correct connections. Check conductor size and voltage ratings for inverter compatibility. Proper conduit selection protects wiring from environmental damage.

Confirm correct breaker size at all disconnect points and ensure system disconnecting switches remain easily accessible. Learn how to size breakers for optimal protection. Every solar system requires proper labeling to meet solar-specific code requirements and enable safe maintenance.

Testing Inverter Functionality and Output

The inverter functions as the system’s central processing unit, converting DC power from panels into AC power for household use and grid connection. Proper inverter function determines overall system performance.

Begin by checking the display for accurate information or error messages. Review inverter output readings to ensure they match expected performance levels for the solar installation.

Examine the unit itself for cracks, discoloration, or signs of heat damage. These indicators may signal internal problems. Verify breakers and fuses remain in good condition and properly rated for the panels.

Confirm rapid shutdown systems function properly, as current NEC standards require these for solar safety.

Document the inverter model and serial number for future reference. This information simplifies warranty service and technical support. This documentation should be part of the overall solar panel inspection checklist.

Fire Safety Protocols and Code Compliance

Implementing Fire Prevention Safety Measures

Fire safety represents a critical aspect of solar panel maintenance that deserves consistent attention on every solar system maintenance checklist. Regular checks for loose connections, damaged insulation, or unusual components prevent small electrical problems from becoming serious fire hazards.

Vigilant monitoring protects both people and property.

This includes examining:

String Fuses and Circuit Breakers: Ensure string fuses and circuit breakers function properly with correct specifications. Review residential inspection guidelines for code compliance. Verify correct breaker size for each circuit and confirm system disconnecting switches display clear labels.

Panel Cleanliness: Remove accumulated dust, dirt, or debris that could cause overheating or reduced efficiency. Each solar panel in the array needs regular cleaning to maintain peak performance.

Electrical System Inspection: Check the electrical system frequently for loose connections, corrosion, or wear signs. Inspect system conductors for damage that could compromise safety or inverter output.

Maintaining Proper System Labeling and Documentation

Correct labeling and documentation of solar installations satisfy legal requirements while simplifying future maintenance and improving safety for inspectors and service personnel. All listed equipment must display proper signage requirements clearly.

During inspections, verify:

All labels showing DC and AC voltage, current ratings, and power output remain present. Solar-specific code requirements mandate clear labeling at all system disconnecting points and on the inverter. Understanding single line diagrams helps verify proper documentation.

All necessary documentation, including safety codes, schematics, and invoices, remains easily accessible. Maintain a complete solar panel inspection checklist with documentation for reference during maintenance. Use the model inspection checklist as a reference standard.

Appropriate authorities have received and approved all necessary permits and inspection paperwork. Solar systems must comply with all NEC standards and local regulations to remain in good standing.

Tracking Solar System Performance Metrics

Analyzing Energy Production and System Efficiency

Evaluating panel performance begins with assessing energy output levels. Efficiency measures how much power panels generate compared to the sunlight they receive. Monitor inverter output regularly to track actual production from the solar installation.

The concept remains straightforward: good efficiency indicates the system performs its intended function. When numbers fall short of expectations, something blocks optimal performance.

Analyze these key metrics:

Conversion Efficiency: The percentage of sunlight the panel converts into electricity.

Annual Energy Production: The total electricity a solar panel generates over a year.

Compare actual output against expected performance. This comparison reveals system health accurately. Each panel inspection should include performance measurements to ensure the array produces as expected. Follow the Energy Ready inspection protocol for thorough assessments.

When actual output matches expectations, the system operates correctly. Discrepancies signal problems requiring closer investigation. This approach represents one of the simplest methods for detecting issues before they worsen.

Regular solar system monitoring identifies problems with individual panels or the entire installation before they significantly impact performance.

Using Real-Time Monitoring Technology

Monitoring panel performance proves as important as installation quality. A monitoring system enables real-time visibility instead of relying on assumptions.

Modern solar installations include monitoring tools that track inverter output, panel performance, and overall system health.

Effective monitoring systems provide clear operational insights. They eliminate guesswork about solar panel functionality by displaying power generation, system efficiency, and emerging issues.

This functions like a vehicle dashboard, telling the complete story at a glance.

A reliable monitoring system includes:

Data Logger: Collects and tracks solar panel performance metrics.

Sensors: Measure sunlight intensity, ambient temperature, and panel temperature.

Data Analysis Software: Analyzes collected data and generates system performance reports.

Monitor performance numbers closely. The data reveals the complete story. Sudden drops in output or efficiency require attention. The cause might be simple: dirt, shade, or weather conditions.

Persistent problems warrant professional investigation by an electrician. Regular reviews identify problems before they escalate into costly repairs. An inspector can perform thorough panel inspection to determine the root cause of solar system performance issues.

Recording Issues and System Deficiencies

Creating Detailed Problem Documentation Logs

Beyond monitoring performance, document all observations carefully. When problems appear, record them immediately. Log everything: cracks, output declines, unusual error codes.

This documentation serves as proof and enables quick problem resolution. The solar panel inspection checklist should include space for documenting all observations during each inspection.

Common problems affecting solar panel performance include:

- Bird droppings, dirt, and dust on panel surfaces

- Shading from nearby trees or buildings

- Malfunctioning inverters or charge controllers affecting inverter output

- Damaged or loose wiring and connections, including system conductors

- Solar cell or encapsulant degradation over time

- System disconnecting switch issues or incorrect breaker size

- Listed equipment problems not meeting solar-specific code requirements

For off-grid solar systems, battery monitoring becomes equally critical.

Document even minor problems. These records prove invaluable for maintenance teams or hired electricians. They review notes, connect patterns, and resolve issues before they escalate.

Quick fixes now extend panel lifespan by years. A detailed panel inspection log helps professionals diagnose and repair issues faster.

Solar installations require active management. Declining numbers demand attention. Performance changes require investigation. Regular system checks keep installations running smoothly and prevent gradual power loss.

Regular inspections ensure solar installations continue meeting NEC standards and operating safely.

When problems exceed DIY capabilities, call qualified professionals. Experienced electricians know regulations, proper tools, and safety protocols. Reference the Raleigh inspection standards for comprehensive requirements. A professional inspector understands signage requirements, proper system conductor sizing, and correct breaker size selection.

Vigilant monitoring combined with professional expertise extends solar investment value long-term. Whether checking roof integrity, verifying rapid shutdown functionality, or ensuring proper listed equipment installation, professionals handle complex solar system maintenance aspects. Solar Permit Solutions provides expert inspection support.

Extending Solar Panel Lifespan Through Proper Care

Establishing Regular Cleaning and Maintenance Schedules

Solar panels require active maintenance to maximize lifespan. Cleaning remains essential. Dust accumulates. Leaves blow across panels. Debris blocks sunlight. Less sunlight means less power generation.

The relationship remains direct. Regular inspections become necessary habits. Each solar panel in the installation deserves attention during maintenance visits.

When cleaning becomes necessary, use proper techniques. Soft brushes, sponges, and gentle handling prevent damage. Harsh tools and rough treatment scratch surfaces, destroying efficiency faster than dirt accumulation.

Proper panel care ensures years of reliable performance.

Maintenance tasks include:

- Checking panels for accumulated dirt and debris

- Gently removing dust and leaves

- Using soft brushes or sponges for cleaning

Proactive Damage Prevention and Repair Strategies

Protecting panels from physical damage proves essential for longevity. Physical damage shortens panel lifespan significantly. Regular inspections identify loose wires, cracks, and wear signs. Ignoring these problems allows them to worsen.

When problems appear, take immediate action. Professional assistance prevents rapid solar system deterioration. Small repairs today prevent major problems tomorrow.

Regular panel inspection catches issues like damaged system conductors, worn roof mounting hardware, or problems with system disconnecting equipment. Consult the Red Wing thermal inspection checklist for additional guidance. Addressing these during routine maintenance prevents costly repairs later.

Ensure all listed equipment remains in good condition and signage requirements stay maintained throughout the solar installation’s life.

Sustaining Peak System Performance

Staying current with panel maintenance keeps systems running smoothly. Skipping maintenance causes performance drops. Monitor the numbers. Track output levels. Even small declines have causes. Investigate them. Address problems promptly.

Clear issues require attention: dust-covered solar panels, encroaching tree shade. Even minor factors reduce production. Vigilant attention ensures systems continue delivering returns. Neglect becomes apparent quickly. For independent installations, off-grid system design requires extra vigilance.

Maintenance practices include:

- Monitoring system output data and inverter output readings

- Maintaining panel cleanliness through regular cleaning

- Preventing shadows from trees or buildings on the array

Conclusion

Regular solar panel inspections represent a fundamental practice for protecting renewable energy investments and ensuring long-term system performance. A comprehensive inspection checklist provides the structure needed to identify potential problems before they escalate into costly repairs or safety hazards. Review the Coon Rapids system checklist for municipal standards. From visual assessments and structural evaluations to electrical testing and performance monitoring, each inspection component serves a critical purpose in maintaining system efficiency.

Professional inspections complement routine maintenance efforts by providing expert analysis of complex system components. Qualified inspectors bring specialized knowledge of NEC standards, local code requirements, and advanced diagnostic tools that reveal issues invisible during casual observation. Their expertise ensures systems remain compliant, safe, and operating at peak capacity.

The investment in regular inspections pays dividends through extended equipment lifespan, optimized energy production, and peace of mind. Property owners who maintain consistent inspection schedules avoid unexpected failures, protect warranty coverage, and maximize returns on their solar installations. For more insights, visit the Solar Permit Solutions blog. A proactive approach to solar system maintenance, guided by a thorough inspection checklist, ensures reliable renewable energy generation for decades to come.

FAQs

The inverter must function correctly, or the entire solar system fails. Check inverter output and verify all system disconnecting switches operate properly. Finally, assess performance. Overall output, monitoring system data, and real-time information should align logically.

Annual inspections may prove insufficient in harsh climates. Some experts recommend biannual inspections. Snow, extreme heat, and storms accelerate wear. The principle remains simple: frequent inspections, early repairs, and solar systems continue delivering purchased energy.

Credentials alone don’t suffice. Qualified inspectors must understand local safety and electrical codes thoroughly. This knowledge keeps systems safe and compliant. They need expertise in NEC standards, solar-specific code requirements, proper system conductor sizing, correct breaker size selection, and signage requirements.

Some inspectors perform IV curve tests for deeper analysis. This test reveals solar panel performance under varying sunlight conditions. Problems become apparent through this testing, identifying non-obvious issues before they become serious performance problems. Reference the IREC plan review guidelines for industry standards.

Specialized tools like irradiance meters and thermal cameras add value to inspections. IV curve testing provides deep analysis of panel performance under varying conditions. Early detection through professional inspection enables repairs before performance seriously declines, ultimately saving money on energy losses and major repairs.

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

A comprehensive checklist covers multiple areas. Begin with the solar panels themselves. Check for dirt, debris, cracks, or anything blocking sunlight. Next, examine hardware. Inspect roof brackets, bolts, and mounting systems for looseness or wear. Review wiring carefully. Connections should show no fraying or burning. The inverter must function correctly, or the entire solar system fails. Check inverter output and verify all system disconnecting switches operate properly. Finally, assess performance. Overall output, monitoring system data, and real-time information should align logically.

Panels require inspection at least annually. This minimum frequency maintains smooth operation. Regular inspections catch unexpected problems: loose wires, weather damage, gradual output declines. A professional inspector can perform thorough solar panel inspection to catch issues early. Annual inspections may prove insufficient in harsh climates. Some experts recommend biannual inspections. Snow, extreme heat, and storms accelerate wear. The principle remains simple: frequent inspections, early repairs, and solar systems continue delivering purchased energy.

Professional solar panel inspectors need specific training and experience in solar installation, maintenance, and inspection. Not everyone qualifies to inspect solar systems. Certifications matter significantly. The North American Board of Certified Energy Practitioners (NABCEP) sets industry standards. Credentials alone don't suffice. Qualified inspectors must understand local safety and electrical codes thoroughly. This knowledge keeps systems safe and compliant. They need expertise in NEC standards, solar-specific code requirements, proper system conductor sizing, correct breaker size selection, and signage requirements.

Solar system inspections extend beyond visual examination. Inspectors conduct tests, sometimes examining individual panels for electrical output and efficiency readings. Tools like irradiance meters and thermal cameras detect problems invisible to the naked eye. Some inspectors perform IV curve tests for deeper analysis. This test reveals solar panel performance under varying sunlight conditions. Problems become apparent through this testing, identifying non-obvious issues before they become serious performance problems.

Professional solar system inspection costs vary based on installation size, array complexity, roof panel accessibility, and additional testing requirements. Most inspectors factor in travel time, thoroughness of testing required to verify NEC standards and solar-specific code requirements are met, and time needed to document findings. Specialized tools like irradiance meters and thermal cameras add value to inspections. IV curve testing provides deep analysis of panel performance under varying conditions. Early detection through professional inspection enables repairs before performance seriously declines, ultimately saving money on energy losses and major repairs.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

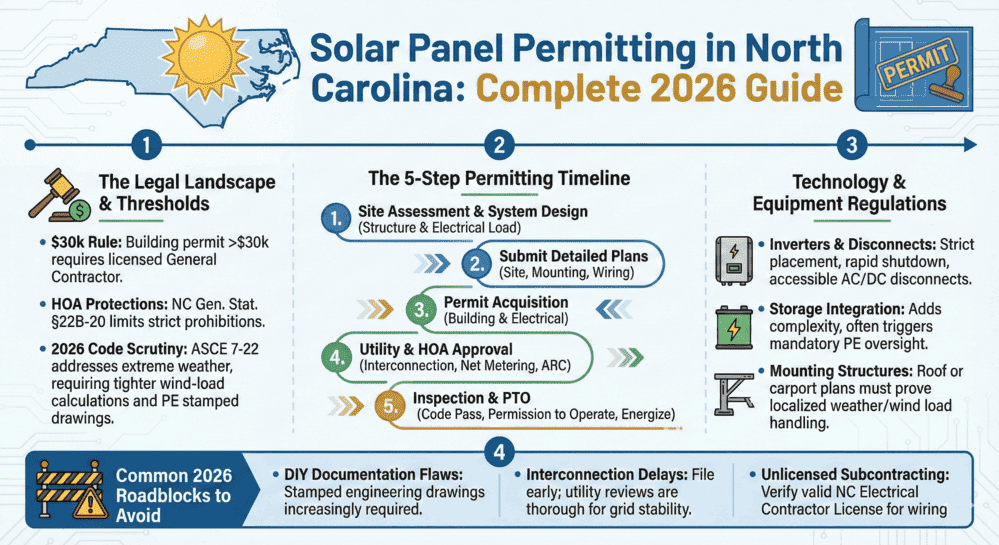

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...