Solar installations in hurricane zones must withstand wind speeds between 140 and 180 mph and comply with ASCE 7-22 wind-load standards, IBC 2024 structural requirements, and state-specific building codes that often exceed federal minimums. Contractors operating in Florida, Gulf Coast states, and coastal regions face mandatory Professional Engineer certification, enhanced fastener specifications, and rigorous Authority Having Jurisdiction review processes before permit approval. This 2025 guide covers the essential engineering calculations, code compliance requirements, and documentation strategies that solar installers need to secure permits for high-wind installations. Projects in high-velocity hurricane zones require hurricane-rated racking systems, increased attachment density, and site-specific structural analysis addressing uplift forces, lateral loads, and exposure categories defined by local wind-speed maps.

Understanding these requirements before submission reduces permit rejection rates and prevents costly redesigns during the approval process.

1. Verify Site-Specific Wind Speed Requirements

Prior to creating any permit documentation, establish the baseline wind velocity for your installation site. Most authorities reference ASCE 7 wind-speed charts, though certain states, including Florida, enforce more rigorous thresholds. Geographic shifts of just a few miles can alter required design velocities by 20 mph or beyond, making coordinate verification with your local Authority Having Jurisdiction (AHJ) essential.

2. Building Codes and Standards for Hurricane-Zone Solar (2025)

High-wind solar engineering relies on multiple regulatory standards:

International Building Code (IBC 2024): Establishes structural load formulas, uplift mitigation, and fastener distribution requirements.

ASCE 7-22: Sets forth wind-load computation methods, incorporating gust multipliers and exposure classifications for shoreline or open-field locations.

National Electrical Code (NEC 2023): Mandates weather-resistant conduit systems, rapid shutdown mechanisms, and robust mounting for rooftop components.

State Modifications: The Florida Building Code and comparable regional supplements frequently surpass federal benchmarks.

Maintaining drawing compliance with current code editions remains vital, as numerous AHJs have transitioned to 2024 IBC protocols. The National Renewable Energy Laboratory provides updated technical resources for solar professionals navigating evolving standards.

3. Engineering Calculations Required for High-Wind Solar Design

Hurricane-force winds generate uplift pressure, horizontal thrust, and rotational stresses that conventional mounting hardware cannot always withstand. Professional engineer-sealed documentation must cover:

Fastening Strategy: Deploy hurricane-certified hardware with tightened spacing intervals.

Panel Retention Areas: Adhere to equipment maker specifications for high-stress zones.

Ballasted Systems (flat roof applications): Integrate wind deflection barriers and edge weighting to eliminate displacement or toppling risks.

Ground-Array Installations: Evaluate extended pile depth and lateral bracing for exposed coastal terrain using proven racking system designs.

When incorporating battery storage, select housings certified for both wind resistance and flood exposure if storm surge threatens the property. Property owners may also qualify for federal tax incentives when upgrading to resilient solar systems.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

4. Essential Documents for Hurricane-Zone Permit Applications

Thorough application packages generally contain:

- Structural Engineering Reports bearing Professional Engineer certification.

- Location-specific wind analysis conducted per ASCE 7 methodology.

- Comprehensive fastener documentation listing hardware type, placement density, and withdrawal strength.

- Equipment specification sheets confirming wind-rating compliance.

Increasing numbers of AHJs mandate pre-installation conferences to validate mounting procedures before permit issuance. Our residential solar design services streamline this coordination process for contractors nationwide. For utility-specific guidance, review our SDG&E interconnection guide for California projects.

5. Utility Interconnection and Insurance Requirements for Coastal Solar

Electric utilities serving hurricane corridors may demand reinforced disconnect switches or customized service-entrance configurations to minimize wind-related failures. Property owners and business operators should additionally revise insurance contracts to verify protection for hurricane-certified solar assets, a value-add that informed contractors can emphasize during consultations. Understanding utility metering requirements proves essential for complete system planning.

Why Partner with Solar Permit Solutions

Hurricane-zone permitting requires exhaustive engineering precision and application rigor. Solar Permit Solutions‘ design and PE-stamping specialists produce location-tailored wind-load assessments, comprehensive structural blueprints, and hands-on AHJ engagement.

By managing these technical complexities, we enable contractors to shorten approval cycles and eliminate expensive plan revisions.

Conclusion

Securing solar permits in hurricane-prone regions demands more than standard installation knowledge. Contractors must navigate heightened wind-load specifications, state-specific code amendments, and rigorous engineering documentation requirements that extend beyond typical residential projects. Success hinges on early wind-speed verification, PE-stamped structural analysis, and proactive communication with local authorities before submission. As climate patterns intensify storm frequency and building departments enforce stricter resilience standards, solar professionals who master high-wind permitting protocols position themselves as trusted partners for coastal property owners. Investing in proper engineering upfront protects both your installations and your reputation while preventing costly delays that can derail project timelines and profit margins. The renewable energy sector continues evolving with new best practices for extreme weather resilience.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Solar systems in hurricane-exposed areas typically must withstand design wind speeds between 140 and 180 mph, depending on your specific location and AHJ requirements. Florida's High Velocity Hurricane Zone (HVHZ), covering Miami-Dade and Broward counties, mandates 180 mph ratings, while other Gulf Coast regions may require 150-160 mph certification. Your exact threshold depends on ASCE 7 wind maps, local amendments, and the building's exposure category. Always verify requirements with your Authority Having Jurisdiction before finalizing equipment selections, as ratings must account for both sustained winds and gust factors that can exceed base speeds by 30% or more.

Most jurisdictions in hurricane zones require Professional Engineer (PE) certification for solar installations, particularly for roof-mounted systems and arrays exceeding 10 kW. The PE stamp validates that your structural calculations, attachment methods, and wind-load analysis meet code requirements for extreme weather conditions. Ground-mounted systems in open coastal exposure also typically need engineering review due to enhanced uplift and overturning forces. Some AHJs may waive this requirement for small residential systems using pre-approved racking with manufacturer certifications, but you should confirm exemption criteria in writing before proceeding without engineering documentation.

The Florida Building Code incorporates stricter wind-load factors, enhanced corrosion protection standards, and mandatory product approval protocols that exceed baseline IBC requirements. The state maintains a Product Approval database where all structural components, including racking, fasteners, and attachments, must receive validation before use. Florida also enforces the High Velocity Hurricane Zone (HVHZ) designation with additional testing protocols for coastal counties. Exposure categories receive different treatment, with open coastal terrain triggering higher design pressures than the same category would generate under standard IBC calculations. Contractors must also address the Florida-specific wind-borne debris region requirements affecting module glazing specifications.

AHJs most frequently reject permits due to inadequate fastener schedules that fail to specify hardware type, spacing intervals, and pull-out resistance values for high-wind conditions. Missing or outdated PE stamps rank second, particularly when structural calculations don't reference current ASCE 7-22 methodology or fail to account for site-specific exposure factors. Incomplete manufacturer data sheets showing wind-resistance certifications cause delays, as do roof attachments that don't comply with building code penetration requirements. Many rejections also stem from electrical plans lacking rapid shutdown compliance or weatherproof conduit specifications mandated by NEC 2023. Submitting pre-construction meeting requests and coordinating attachment details with plan reviewers before formal submission significantly reduces rejection rates.

Ballasted ground-mount systems face substantial challenges in hurricane zones due to extreme uplift forces and potential projectile hazards during wind events. Most coastal AHJs require mechanical anchoring through driven piles, helical foundations, or concrete footings rather than relying solely on weight for system stability. If ballast approaches receive approval, engineering calculations must demonstrate resistance to sliding, overturning, and progressive collapse under design wind loads, typically necessitating significantly increased weight compared to standard applications. Wind deflector barriers, perimeter reinforcement, and reduced array heights become mandatory design features. For projects within flood zones, ballasted systems present additional complications since FEMA regulations prohibit obstructions that impede water flow, making mechanically anchored solutions the preferred approach for most hurricane-exposed installations.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

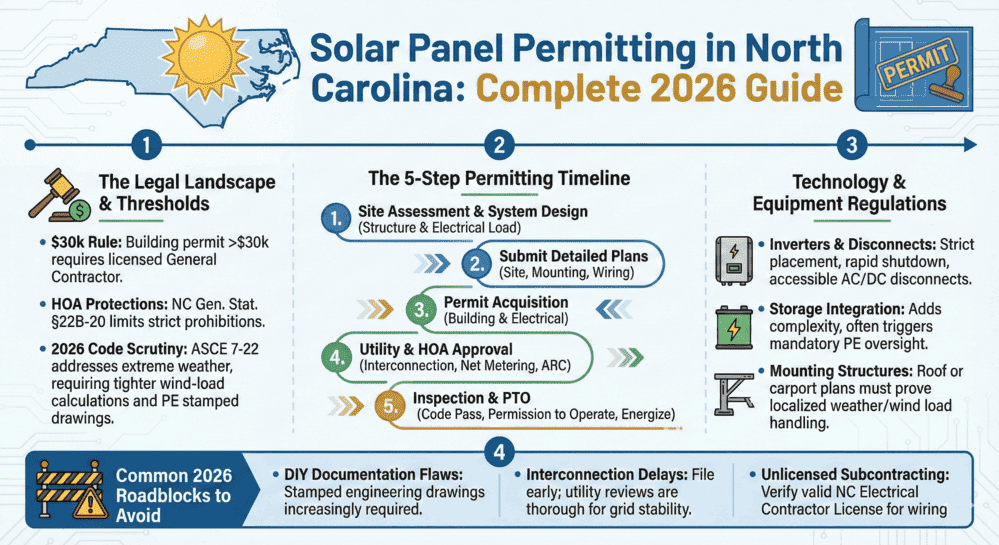

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...