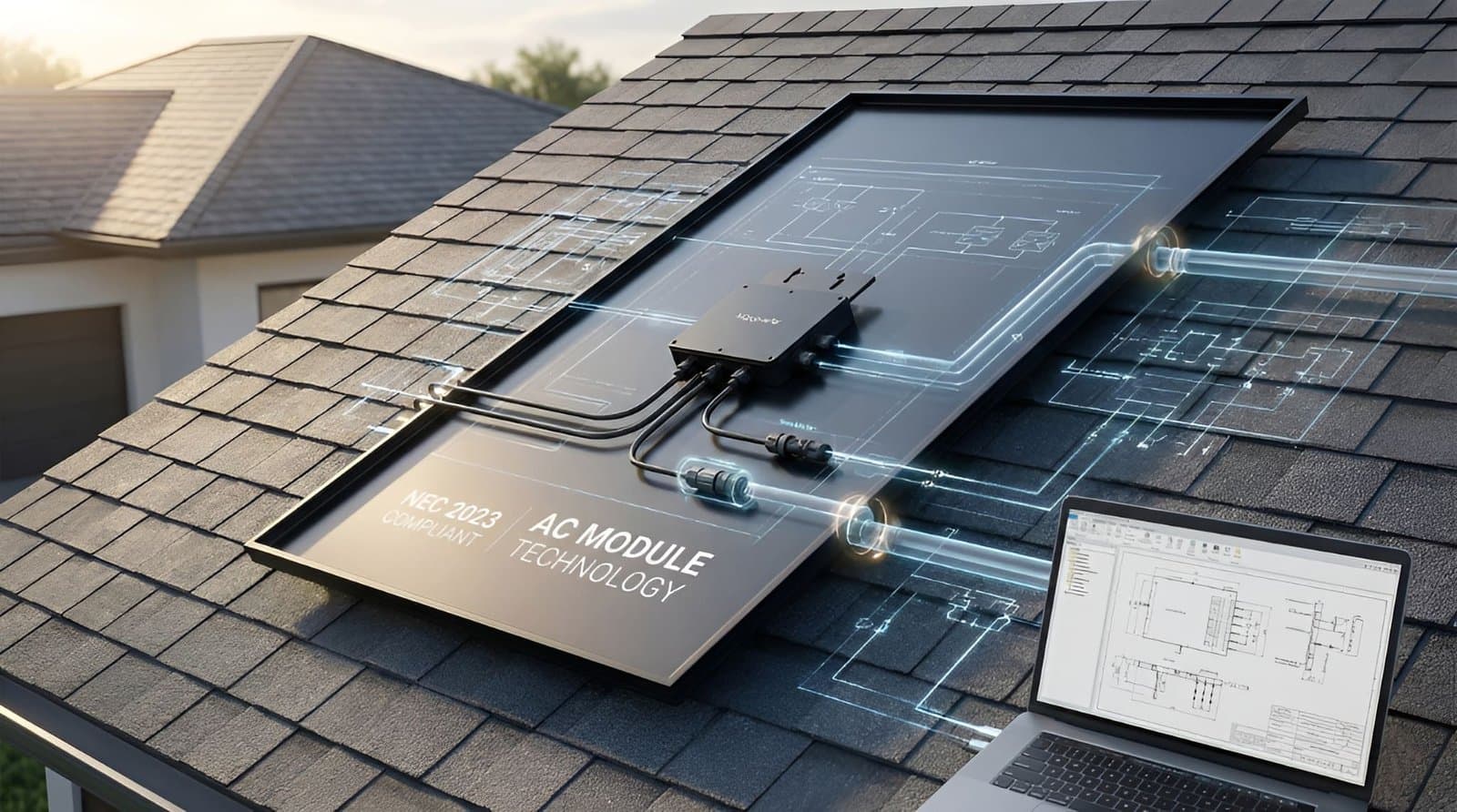

NEC 690.6 establishes unique requirements for AC modules in solar photovoltaic systems by exempting them from traditional DC source circuit regulations. Unlike standard solar installations, AC modules integrate a solar panel with a microinverter into a single UL-listed assembly, fundamentally changing how these systems are treated under electrical code.

The critical distinction: NEC 690.6(A) states that Article 690 requirements for photovoltaic source circuits do not apply to AC modules because all DC circuitry exists as internal wiring within the listed assembly. This exemption eliminates requirements for DC conductor protection under NEC 690.31, DC ground fault detection equipment, arc fault circuit interrupters, and certain rapid shutdown provisions that apply to traditional systems. These systems offer advantages like simplified installation and reduced complexity.

However, inspection authorities frequently misapply code requirements to AC module systems. Many jurisdictions continue treating AC modules identically to standard microinverter installations, requiring DC circuit protections that NEC 690.6 explicitly exempts. This confusion creates permitting delays, unnecessary equipment costs, and rejected applications despite systems being fully code-compliant. Professional commercial solar design and residential installations both face these challenges.

The problem intensifies with factory-paired modules and microinverters that are not listed as complete AC module assemblies. These configurations occupy a gray area where inspectors must determine whether exposed DC wiring requires NEC 690.31 conductor protection, even though components arrive as integrated units. Understanding which products qualify as true AC modules under NEC 690.6 versus discrete components becomes essential for successful permitting.

The Widespread Permitting Confusion Around AC Module Systems

Recent code cycles and industry adoption patterns have revealed significant confusion about how AC modules should be treated under NEC Article 690. The complexity stems from their hybrid nature combining PV technology with integrated conversion equipment.

AC modules are UL listed as complete assemblies consisting of a solar panel with an integrated microinverter. This listing distinction fundamentally changes how the system is viewed under electrical codes. Because the DC circuitry exists entirely within the module assembly as internal wiring, these systems technically eliminate DC source circuits from field installation requirements.

However, inspection practices vary widely across jurisdictions. Many authorities having jurisdiction continue to treat AC modules identically to standard microinverter systems, applying DC circuit requirements that technically do not apply. This inconsistency creates permitting challenges and can lead to unnecessary design modifications or rejected applications.

The confusion intensifies with systems using factory-paired microinverters that are not listed as complete AC module assemblies. These pre-assembled configurations occupy a gray area where DC leads are present but integrated during manufacturing. Inspectors must determine whether exposed DC wiring between the module and microinverter falls under NEC 690.31 conductor protection requirements, even though the components arrive as a single unit.

To summarize, AC modules offer simplified installation and reduced DC circuit concerns but face inconsistent code interpretation. Understanding the specific exemptions provided under NEC 690.6 becomes critical for proper system design and successful permitting.

Breaking Down NEC 690.6 Requirements And Code Exemptions

Code Evolution and Definition

NEC 690.6 underwent significant revisions in the 2020 code cycle to address AC module systems more comprehensively. The 2020 and subsequent 2023 NEC updates expanded exemptions to cover not just individual AC modules but entire AC module systems. Understanding Article 690 fundamentals helps clarify these distinctions.

The key distinction lies in how the code treats internal versus field wiring. NEC 690.6(A) specifically states that Article 690 requirements pertaining to photovoltaic source circuits do not apply to AC modules or AC module systems. The photovoltaic source circuit, conductors, and inverters are considered internal wiring of the AC module assembly.

This exemption has profound implications. Traditional NEC 690 requirements for DC conductor protection, arc fault detection, rapid shutdown, and other DC-specific safety measures become inapplicable. The output of an AC module is classified solely as an inverter output circuit under NEC 690.6(B), meaning it follows AC wiring requirements similar to any other branch circuit.

However, the definition requires that the assembly be listed as an AC module. Systems using discrete components, even when factory-paired, do not receive the same treatment. This creates a marketplace distinction that affects both product selection and installation approaches.

Disconnecting Means Requirements

NEC 690.6(C) addresses disconnection for AC module systems with specific provisions. A single disconnecting means in accordance with 690.15 and 690.17 is permitted for the combined AC output of one or more AC modules. This simplifies installation compared to traditional PV systems requiring multiple disconnection points, particularly beneficial for residential solar design projects.

Additionally, each AC module in a multiple AC module system must be provided with a connector, bolted, or terminal-type disconnecting means. This requirement typically is satisfied through the plug-and-play connectors that AC modules use for interconnection. The connectors themselves serve as the individual disconnection points.

Understanding this distinction helps avoid over-engineering disconnect solutions. Many installers accustomed to string inverter systems attempt to add unnecessary disconnects, increasing costs and complexity without improving safety or code compliance.

Ground Fault Detection Simplification

Traditional DC PV systems require ground fault detection and interruption equipment to prevent fires caused by DC ground faults. NEC 690.6(D) modifies these requirements for AC module systems. Alternating current systems are permitted to use a single detection device to detect only AC ground faults and to disable the array accordingly.

This simplification stems from the elimination of field-accessible DC circuits. Without DC source circuits requiring protection, the ground fault detection strategy shifts entirely to the AC side. Standard GFCI protection or equipment grounding fault protection becomes sufficient.

The reduced complexity in ground fault protection represents one of the primary installation advantages of AC module systems. Design time decreases, component costs reduce, and troubleshooting becomes more straightforward. These benefits apply to grid-tied installations and off-grid systems alike.

Inspector Interpretation Challenges

Despite clear code language, field enforcement remains inconsistent. Many electrical inspectors lack familiarity with AC module systems and default to applying standard PV requirements. This can result in requests for DC disconnects, rapid shutdown systems, or arc fault protection devices that NEC 690.6 explicitly exempts.

The challenge intensifies when systems use modules with visible DC leads, even when listed as complete AC module assemblies. Visual appearance suggests DC circuitry requiring protection, prompting inspectors to cite violations of NEC 690.31 conductor requirements. These citations are technically incorrect but require education and documentation to resolve.

Some jurisdictions have developed specific plan check criteria for AC modules to address this confusion. These jurisdictions require submittal of listing documentation proving the assembly meets AC module definitions. While adding a documentation step, this approach provides clarity and reduces back-and-forth during permitting.

Proven Strategies For Smooth AC Module Permitting And Installation

As the solar industry continues adapting to AC module technology, several strategies can streamline permitting and ensure code-compliant installations. Taking proactive steps during design and documentation phases prevents costly delays and modifications. Professional permitting services help navigate these requirements. Many local jurisdictions now provide specific guidance for AC module systems.

Verify Complete Listing Documentation: Confirm that selected products are actually listed as AC modules, not simply modules with attached microinverters. Obtain and review the complete UL listing to verify the assembly meets AC module definitions. Include this documentation in permit submittals to preempt inspector questions about whether DC circuit requirements apply.

Educate Inspection Authorities Early: For jurisdictions unfamiliar with AC module systems, schedule pre-application meetings to review the technology and applicable code sections. Bring NEC 690.6 language and listing documentation to these meetings. Building inspector understanding before formal plan submission significantly reduces approval timelines and revision requests.

Provide Clear One-Line Diagrams: Create electrical diagrams that clearly identify components as AC modules rather than separate PV modules and inverters. Label outputs as “AC Module Inverter Output Circuit” to reinforce that DC source circuits do not exist in the field installation. This visual clarity helps inspectors quickly understand the system configuration. Proper labeling requirements further enhance clarity.

Document Disconnection Methods: Clearly identify how the installation meets NEC 690.6(C) requirements for both combined and individual disconnecting means. Show the location of the main AC disconnect serving all modules and note that module-level connectors satisfy individual disconnect requirements. Ambiguity about disconnect compliance frequently triggers plan review questions.

Specify Ground Fault Protection Approach: Include documentation showing how the system provides AC ground fault detection per NEC 690.6(D). Specify whether standard GFCI protection, equipment ground fault protection, or other listed methods will be employed. Addressing this requirement explicitly in plans prevents assumptions that DC ground fault equipment is needed.

Maintain Manufacturer Installation Instructions: Keep complete installation manuals readily available during inspection. NEC 110.3(B) requires installation in accordance with listing instructions, making these documents legally binding. Inspectors may reference instructions to verify compliance, so ensuring field crews have current versions prevents violation citations.

Leverage Standard Plan Check Options: Many jurisdictions offer expedited standard plan options for residential systems under 10kW. These plans often include specific sections for AC module or microinverter systems. Using jurisdiction-provided templates when available dramatically accelerates approval and ensures all required information is included. Understanding overcurrent protection and system fundamentals ensures comprehensive compliance.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Conclusion

AC modules represent a significant advancement in solar installation technology, offering simplified wiring and reduced DC circuit concerns when properly documented. However, the benefits can only be realized when installers, engineers, and inspection authorities fully understand the unique exemptions provided under NEC 690.6. Solar Permit Solutions specializes in navigating these complex requirements.

Success with AC module installations requires a proactive approach. Thorough documentation of listing information, clear electrical diagrams, and early engagement with inspection authorities all contribute to smoother project approval. Understanding the specific exemptions regarding DC source circuits, ground fault detection, and disconnection means prevents over-engineering while maintaining full code compliance.

The solar industry benefits when all stakeholders understand and properly apply NEC 690.6 requirements. By investing time in proper documentation and education, installation teams position themselves for faster permitting, reduced costs, and long-term success with AC module technology.

Need help navigating AC module permitting for your specific project? Solar Permit Solutions provides expert design and code-compliant submission support nationwide. Explore more solar code resources for additional guidance.

FAQs

This distinction is critical because true AC modules receive exemptions from NEC 690 DC source circuit requirements since all DC wiring is considered internal to the listed assembly. Systems using separate components must comply with traditional DC circuit protection, conductor requirements, and other Article 690 provisions that AC modules avoid.

However, the AC output circuits must still comply with applicable disconnection requirements under NEC 690.6(C). The specific rapid shutdown approach depends on system configuration and local jurisdiction interpretation, making early consultation with the authority having jurisdiction advisable.

Different manufacturers may use incompatible interconnection systems, monitoring platforms, or voltage/frequency specifications. Additionally, warranty coverage often requires using matched system components. From a permitting standpoint, mixing manufacturers increases documentation complexity since each module type requires separate listing verification and specification sheets.

Create submittal documentation clearly labeling components as “AC Module” on electrical diagrams and specifications. Consider scheduling a pre-application meeting with inspection authorities to review this documentation before formal plan submission, especially in jurisdictions unfamiliar with AC module technology. For complex projects, contact professionals for assistance.

Standard GFCI protection or equipment ground fault protection devices appropriate for AC circuits typically satisfy this requirement. The specific approach should be documented in permit submittals to clarify compliance and prevent assumptions that DC ground fault equipment is needed.

AC modules can reduce installation labor through simplified wiring and fewer connection points. Permitting may proceed faster with reduced documentation requirements and fewer inspector questions about DC circuit compliance. Some jurisdictions offer expedited review for AC module systems, further reducing soft costs. Equipment warranty considerations also factor into long-term value, as single-assembly warranties may differ from separate component coverage. Overall cost-effectiveness depends on project-specific variables including system size, jurisdiction requirements, and labor rates.

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

An AC module is a UL-listed complete assembly consisting of a solar panel with an integrated microinverter tested and listed as a single unit. Regular solar panels with separate microinverters, even when factory-paired, are treated as discrete components. This distinction is critical because true AC modules receive exemptions from NEC 690 DC source circuit requirements since all DC wiring is considered internal to the listed assembly. Systems using separate components must comply with traditional DC circuit protection, conductor requirements, and other Article 690 provisions that AC modules avoid.

AC module systems generally have simplified rapid shutdown requirements compared to traditional DC systems. Since NEC 690.6(A) exempts AC modules from Article 690 requirements pertaining to photovoltaic source circuits, the DC rapid shutdown provisions do not apply to the internal module wiring. However, the AC output circuits must still comply with applicable disconnection requirements under NEC 690.6(C). The specific rapid shutdown approach depends on system configuration and local jurisdiction interpretation, making early consultation with the authority having jurisdiction advisable.

Mixing AC modules from different manufacturers is technically permissible from a code perspective, as each module operates as an independent AC power source. However, practical considerations may limit this approach. Different manufacturers may use incompatible interconnection systems, monitoring platforms, or voltage/frequency specifications. Additionally, warranty coverage often requires using matched system components. From a permitting standpoint, mixing manufacturers increases documentation complexity since each module type requires separate listing verification and specification sheets.

Proving AC module qualification requires comprehensive listing documentation from the manufacturer. Obtain the complete UL listing showing the module and integrated inverter are tested and certified as a single assembly, not as separate components. Include the manufacturer's installation instructions explicitly stating the product is an AC module per NEC definitions. Create submittal documentation clearly labeling components as AC Module on electrical diagrams and specifications. Consider scheduling a pre-application meeting with inspection authorities to review this documentation before formal plan submission, especially in jurisdictions unfamiliar with AC module technology.

AC module systems have simplified ground fault protection requirements compared to traditional DC systems. NEC 690.6(D) permits AC module systems to use a single detection device to detect only AC ground faults and disable the array accordingly. This eliminates the need for DC ground fault detection equipment required in traditional systems. Standard GFCI protection or equipment ground fault protection devices appropriate for AC circuits typically satisfy this requirement. The specific approach should be documented in permit submittals to clarify compliance and prevent assumptions that DC ground fault equipment is needed.

AC modules typically carry a price premium compared to purchasing solar panels and microinverters separately. However, total installed cost comparisons must account for several factors beyond equipment pricing. AC modules can reduce installation labor through simplified wiring and fewer connection points. Permitting may proceed faster with reduced documentation requirements and fewer inspector questions about DC circuit compliance. Some jurisdictions offer expedited review for AC module systems, further reducing soft costs. Equipment warranty considerations also factor into long-term value, as single-assembly warranties may differ from separate component coverage. Overall cost-effectiveness depends on project-specific variables including system size, jurisdiction requirements, and labor rates.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

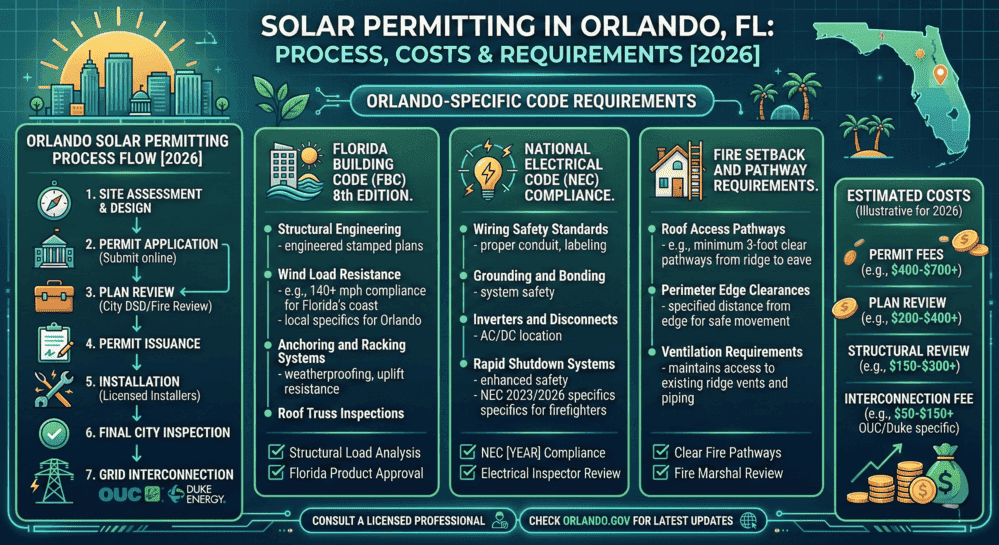

Solar Permitting in Orlando, FL: A Complete Guide for Homeowners & Installers

Solar permitting in Orlando, FL, requires a building permit and an electrical pe...

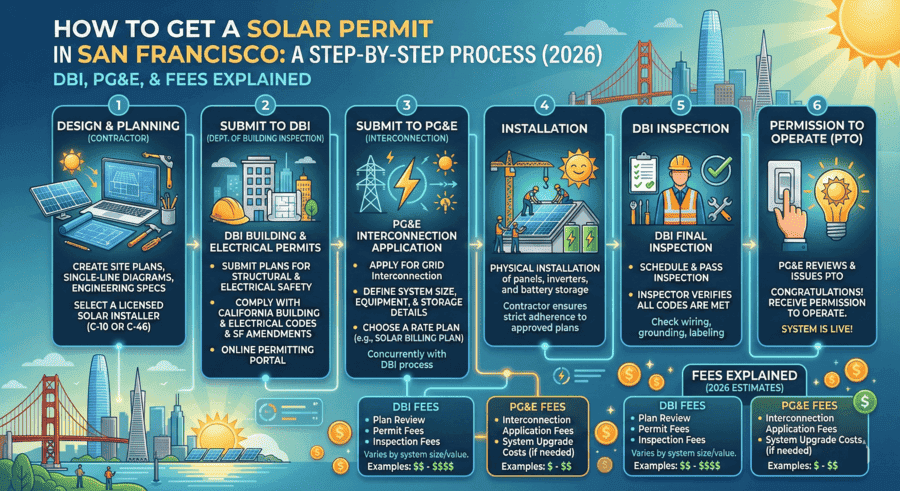

How To Get A Solar Permit In San Francisco: DBI, PG&E And Fees Explained (2026)

San Francisco solar permits require two separate approvals before your system ca...

Bifacial Solar Panel Installation And Permitting Guide

Bifacial solar panels generate 10 to 30 percent more energy than traditional mon...