NEC 705.13 allows solar installers to bypass the traditional 120% busbar rule by using Energy Management Systems (EMS) to control power flow from solar PV systems. This code provision, introduced in the 2020 National Electrical Code and refined in the 2023 NEC, enables larger solar installations on existing electrical service equipment without requiring costly panel upgrades or main breaker derating.

Key benefits of NEC 705.13 compliance:

- Install 15kW to 20kW+ solar systems on standard 200A service panels

- Eliminate $3,000 to $8,000 service upgrade costs

- Dynamically manage solar and battery storage export limits

- Maintain full NEC compliance with listed EMS devices

An Energy Management System under NEC 705.13 must be a listed control device that continuously monitors system output, automatically limits current flow when approaching maximum thresholds, and includes fail-safe mechanisms that default to non-export conditions during failures. The system cannot be a standard programmable logic controller or basic smart inverter setting.

This guide covers NEC 705.13 requirements, compliant EMS products, permitting documentation, and practical implementation strategies for solar contractors working with residential and commercial photovoltaic installations.

Defining Energy Management Systems In Solar Applications

An Energy Management System (EMS) functions as a listed control device or software-based platform that monitors and restricts power flow from distributed energy resources like solar PV, battery storage, or generators. This prevents overloading of busbars, feeders, or conductors.

Simply put, an EMS acts as an intelligent gatekeeper that keeps systems within the limits established by the National Electrical Code (NEC).

Through dynamic current flow control, EMS enables larger PV installations without requiring physical upgrades to panels or service equipment.

The 120% Rule Challenge That Created The Need For EMS

Prior to EMS, designers faced constraints from the NEC 705.12(B)(2) “120% rule,” which specifies that the combined total of the main breaker and PV breaker cannot surpass 120% of the busbar rating.

For instance, a 200A panel could accommodate only up to 40A of backfed PV (approximately 9.6 kW at 240V). Increasing capacity required derating the main breaker or upgrading the service, both costly alternatives.

NEC 705.13 addresses this challenge by providing a dynamic approach to power flow management without hardware modifications.

Operational Mechanics Of NEC 705.13 Systems

Under NEC 705.13, an EMS controls:

- PV inverter output

- Energy storage discharge

- Combined system export

This ensures that busbar ratings, feeder ampacity, or service capacity remain within safe limits, even during maximum solar production and grid load conditions.

The EMS must continuously monitor system output, automatically restrict current flow when approaching maximum thresholds, and be listed and approved for energy management applications.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Practical Implementation Strategies For Solar Contractors

Solar contractors can leverage NEC 705.13 in several strategic ways.

Maximizing Solar Capacity On Existing Service Equipment

When installing 15kW or 20kW of solar on a 200A service panel, a listed EMS can actively limit system export to ensure combined current stays within safe busbar limits.

This approach eliminates the need for service upgrades, avoids main breaker derating, and maintains full compliance with NEC 705.13.

Managing Combined Solar And Battery Systems

Solar and storage combinations can produce total exportable current exceeding busbar ampacity. An EMS monitors both sources and prevents overloads dynamically.

Consider this scenario:

- PV Inverter: 60A

- Battery Inverter: 40A

- Busbar: 100A maximum

The EMS maintains combined current below 100A by throttling PV output or limiting discharge. Proper connector selection ensures safe system operation.

Coordinating Commercial Multi-Source Installations

Commercial installations frequently utilize multiple inverters across feeders. EMS can coordinate all generation sources to preserve safe system limits, allowing flexible interconnections under a single service.

NEC 705.13 Equipment Standards And Approval Requirements

To qualify under NEC 705.13, the Energy Management System must be listed and identified for power control, prevent overloads of busbars, conductors, and overcurrent devices, and maintain safe operation under all load and generation scenarios.

Critical fail-safe requirement: if the system fails, it must default to a non-export or shutoff state.

Standard programmable logic controllers (PLCs) or smart inverter settings do not meet these requirements. The system must be a certified EMS product approved by the Authority Having Jurisdiction (AHJ). Understanding NEC exemptions helps contractors navigate compliance requirements effectively.

Available EMS Products For Solar Integration

Early market adopters include systems with export-limiting capabilities and dynamic power control functions.

Product listings and certifications per UL 1741 SB or UL 916 should always be verified for compliance.

Required Permit Documentation For EMS Projects

When incorporating an EMS into system design, permit packages should include:

- Single-line diagram displaying control architecture

- Manufacturer specification sheet confirming EMS listing and functionality

- Load calculations demonstrating controlled limits

- System operation notes referencing NEC 705.13 compliance

Many AHJs now specifically request documentation showing EMS functionality per NEC 705.13. Providing these details upfront accelerates permit approval timelines.

Installation Best Practices For Field Teams

Proper EMS configuration must be verified before final inspection. System disconnects should be clearly labeled to reflect EMS integration, similar to rapid shutdown requirements. Coordination with utility interconnection teams is essential, as some utilities require export-limiting verification during Permission to Operate (PTO) processes.

Maintaining screenshots or commissioning reports that demonstrate export limits and real-time monitoring capabilities proves valuable during inspections. Proper labeling requirements should be followed for all EMS-controlled systems.

The Growing Role Of EMS In Distributed Solar

As distributed generation expands, grid export control will become mandatory in numerous jurisdictions. NEC 705.13 provides contractors with the flexibility to construct larger, smarter, and safer systems without waiting for service upgrades or expensive hardware modifications.

This regulation bridges traditional PV design with the future of smart grid-ready solar infrastructure.

Conclusion

NEC 705.13 represents a transformative shift in how solar professionals approach system sizing and interconnection design. Energy Management Systems eliminate many of the traditional barriers that previously restricted solar capacity on existing electrical infrastructure.

The ability to install larger PV arrays without costly service upgrades opens new market opportunities for residential and commercial solar contractors. Projects that were once economically unfeasible due to panel replacement or main breaker derating costs can now move forward with EMS integration.

However, success with NEC 705.13 requires careful attention to equipment selection, proper system configuration, and thorough documentation. The EMS must be a listed device that meets fail-safe requirements, and installers must work closely with AHJs to ensure all compliance standards are met.

As grid interconnection standards continue to evolve, EMS technology will become increasingly central to solar design practices. Solar professionals who master NEC 705.13 applications position themselves at the forefront of industry innovation, capable of delivering advanced solutions that maximize system performance while maintaining code compliance and electrical safety.

The transition to smart, grid-responsive solar installations is underway, and NEC 705.13 provides the regulatory framework that makes this evolution possible.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

No, not every smart inverter qualifies as an EMS under NEC 705.13. The system must be specifically listed and identified for energy management and power control functions. While many modern inverters have export-limiting capabilities, they must meet the specific certification requirements outlined in UL 1741 SB or UL 916 to be considered compliant EMS devices. Always verify that the equipment is approved by your local Authority Having Jurisdiction before incorporating it into system designs.

Using an EMS does not eliminate the need for utility approval, but it can streamline the interconnection process. Utilities still require standard interconnection applications and may have specific requirements for export-limiting documentation. Some utilities actually require export-limiting verification during the Permission to Operate process. Solar contractors should coordinate with utility interconnection teams early in the project to understand their specific EMS documentation requirements and ensure smooth approval.

NEC 705.13 requires that all compliant EMS devices include fail-safe mechanisms. If the system experiences a malfunction or loses communication, it must automatically default to a non-export condition or complete system shutoff. This safety feature prevents any possibility of overloading busbars, feeders, or service equipment during system failures. The fail-safe requirement is a critical component of EMS certification and one of the reasons why standard programmable logic controllers cannot be used as substitute devices.

Yes, EMS can often be retrofitted to existing solar installations to enable capacity expansion. This approach is particularly valuable for homeowners or businesses that initially installed smaller systems and now want to add more panels. However, the existing inverter must be compatible with the EMS device, or the system may require inverter replacement. A qualified solar designer should evaluate the existing installation to determine the best path forward for EMS integration and capacity expansion. Professional installation services can help assess compatibility and system requirements, unlike DIY approaches which may miss critical integration details.

EMS devices typically cost between $1,000 and $3,000 depending on the manufacturer and system complexity, while electrical service upgrades can range from $3,000 to $8,000 or more. The cost advantage of EMS becomes even more significant when factoring in the reduced labor, permitting fees, and utility coordination required for service upgrades. For projects where the 120% rule would otherwise limit system size, EMS integration offers substantial cost savings while enabling larger solar installations that improve project economics and customer return on investment.

Yes, NEC 705.13 applies to all types of solar installations where distributed energy resources connect to electrical service equipment. The code section covers residential, commercial, and industrial applications. However, the complexity of EMS implementation may vary significantly between project types. Residential systems typically involve simpler EMS configurations with single inverters or combined solar-plus-storage systems, while commercial installations may require more sophisticated coordination across multiple inverters, feeders, and generation sources. Regardless of project size, the fundamental compliance requirements remain the same.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

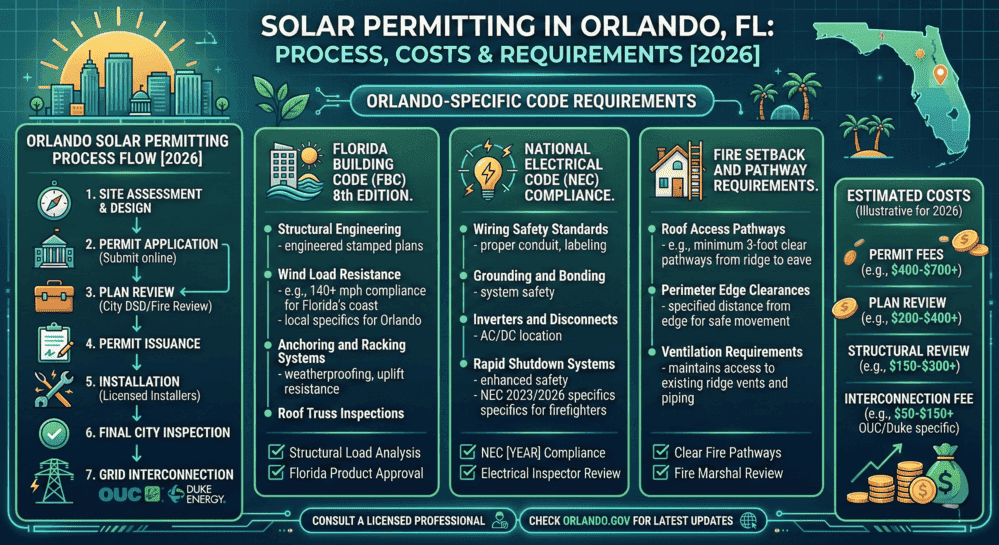

Solar Permitting in Orlando, FL: A Complete Guide for Homeowners & Installers

Solar permitting in Orlando, FL, requires a building permit and an electrical pe...

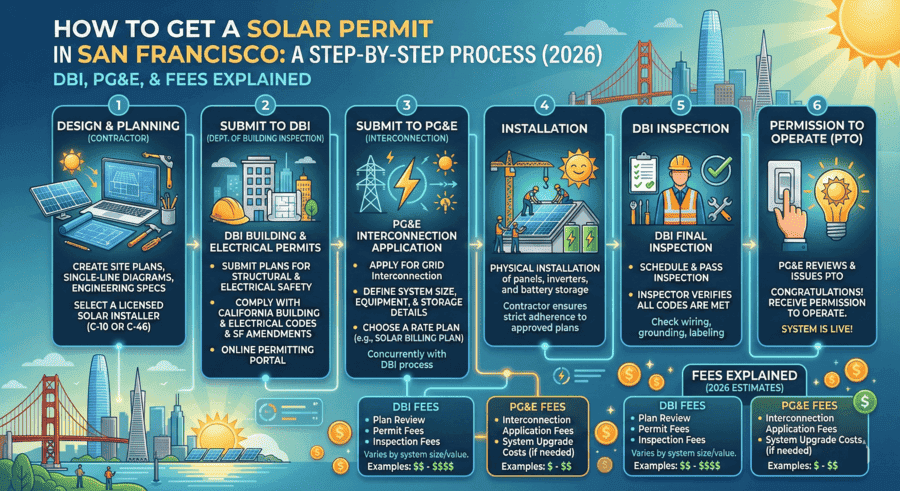

How To Get A Solar Permit In San Francisco: DBI, PG&E And Fees Explained (2026)

San Francisco solar permits require two separate approvals before your system ca...

Bifacial Solar Panel Installation And Permitting Guide

Bifacial solar panels generate 10 to 30 percent more energy than traditional mon...