A solar PV commissioning inspection is a systematic evaluation of a newly installed photovoltaic system that verifies proper installation, safety compliance, and expected performance before the system begins operation. This process includes visual inspections, electrical testing (voltage, current, grounding, insulation resistance), and performance verification against design specifications. Commissioning is required for all grid-connected solar installations and must be completed before utilities grant Permission to Operate (PTO).

Proper commissioning protects system owners by confirming energy output meets expectations, validating warranties, satisfying insurance requirements, and ensuring compliance with the National Electrical Code (NEC) Article 690 and international standards like IEC 62446. With over 63 GW of solar capacity added in the United States in 2024, thorough commissioning has become essential for protecting the significant investment property owners make in solar technology. Documentation from commissioning may also be required to qualify for the 30% federal solar Investment Tax Credit (ITC).

Key Takeaways:

- A commissioning inspection is a mandatory final check before your utility grants Permission to Operate (PTO).

- It verifies your system is safe, performs as expected, and meets all electrical codes (NEC Article 690, IEC 62446).

- Common deficiencies include wire management failures (found on 38% of projects), grounding issues, and labeling problems.

- The process protects your investment, validates warranties, and supports insurance claims.

- Always ensure your installer provides a complete commissioning report before system activation.

Understanding The Solar PV Commissioning Process

A commissioning inspection is a thorough evaluation of a newly installed solar PV system conducted before the system becomes operational. This critical process ensures all components are properly installed, functioning as intended, and meeting project specifications, industry codes, and safety standards.

The inspection process typically occurs after construction is complete but before the utility grants Permission to Operate (PTO). During this phase, qualified personnel conduct systematic tests and visual assessments to verify that every aspect of the installation meets design requirements and regulatory compliance standards. The field inspection guidelines published by industry organizations provide standardized checklists for this process.

Commissioning inspections serve multiple stakeholders in the solar installation process. System owners gain confidence that their investment will perform as expected. Installers demonstrate professional workmanship and reduce callback risks. Utilities and local authorities verify that interconnected systems will not pose safety hazards to workers or the electrical grid. Insurance providers require documentation proving proper installation to validate coverage.

Critical Benefits Of Proper System Commissioning

Commissioning provides several essential benefits that protect all parties involved in a solar installation. Understanding these benefits helps property owners and project managers appreciate why this step should never be overlooked or rushed.

Performance Verification

Commissioning confirms that the system generates energy at expected levels under real-world conditions. This process identifies and addresses issues like wiring errors, shading problems, or underperforming modules before they impact long-term energy production. Performance testing compares actual output against theoretical calculations based on equipment specifications, adjusted for environmental conditions such as available sunlight and module temperature. A properly commissioned system should achieve a Performance Ratio within acceptable parameters, typically demonstrating that actual output aligns closely with expected production.

Safety Assurance

Safety verification represents one of the most critical aspects of commissioning. Inspectors verify proper installation of electrical connections, grounding, and protective devices to mitigate risks of fire, electrical shock, or equipment damage. According to industry data, wire management failures occur on approximately 38% of PV projects installed nationwide, highlighting the importance of thorough inspection. Proper grounding is essential for system stability and reliability, yet improperly grounded systems remain a common finding during commissioning inspections. Avoiding common installation mistakes significantly reduces safety risks.

Regulatory Compliance

Meeting requirements for grid interconnection approvals from jurisdictions and utility providers requires documented proof of code compliance. Local governments have different laws and regulations pertaining to permitting and inspection processes, which can vary significantly across the approximately 20,000 distinct jurisdictions in the United States. Commissioning documentation demonstrates that the installation meets all applicable building, electrical, and safety codes enforced by the Authority Having Jurisdiction (AHJ). Comprehensive inspection training resources help standardize this process across jurisdictions.

Documentation And Warranty Protection

Commissioning provides evidence of proper installation, supporting warranty validation and insurance claims if needed in the future. The handover documentation package becomes critical for effective system maintenance over time. Missing documentation may cause unforeseen complications if the system owner intends to sell the property or transfer the asset to a new owner. Manufacturers often require commissioning verification to honor equipment warranties, making this documentation essential for protecting the system investment.

Key Standards And Code Requirements

Solar PV commissioning must comply with multiple standards and codes that establish safety and performance requirements. Understanding these standards helps ensure installations meet all applicable requirements.

IEC 62446 International Standard

IEC 62446-1:2016+A1:2018 defines the information and documentation required to be handed over to customers following the installation of a grid-connected PV system. This international standard describes commissioning tests, inspection criteria, and documentation expected to verify safe installation and correct operation. The standard applies to grid-connected PV systems and provides a template for system designers and installers to deliver effective documentation. Different test regimes are defined for various PV system types to ensure appropriate testing based on scale, type, and complexity.

National Electrical Code Article 690

The National Electrical Code (NEC) establishes foundational requirements for all solar PV installations in the United States. Article 690 specifically addresses solar photovoltaic systems, covering design, installation, operations, commissioning, and maintenance requirements.

The 2023 NEC introduced several significant updates affecting commissioning requirements. Changes to Article 690.12 refined rapid shutdown system (RSS) requirements for both residential installations and commercial installations, with emphasis on clear, consistent, and highly visible labeling that helps firefighters, inspectors, and maintenance personnel quickly identify rapid shutdown capabilities during emergencies. Updates to Article 690.43 now specify best practices for bonding metal parts, mounting hardware, and equipment enclosures while ensuring correct conductor sizing and continuity.

Article 706.7(A) in the 2023 NEC introduced new commissioning requirements for energy storage systems (ESS), outlining specific procedures that installers must follow including step-by-step testing, documentation, and certification requirements. These requirements apply to both grid-tied and off-grid system design configurations.

OSHA Safety Procedures

Occupational Safety and Health Administration (OSHA) requirements establish workplace safety standards that apply during commissioning activities. These procedures protect workers conducting inspections and testing while ensuring that completed installations do not pose ongoing safety hazards.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Who Performs Commissioning Inspections?

Several types of qualified personnel may conduct commissioning inspections, depending on the project scope, local requirements, and stakeholder needs. The project commissioning guidelines outline qualification requirements for different inspection roles.

Installation Contractors

The solar installation company typically performs internal commissioning as part of their quality assurance process. This initial commissioning verifies that workmanship meets company standards and project specifications before requesting official inspections from local authorities. The PV installation guide provides additional reference materials for installation verification.

Authority Having Jurisdiction Inspectors

After the installer completes internal quality checks, local government officials inspect the installation to verify compliance with building, electrical, and fire codes. These AHJ inspections are coordinated and documented as a prerequisite to obtaining utility approval to operate the interconnected solar PV system. Inspection requirements may include electrical, fire, and seismic assessments depending on local requirements.

Utility Company Representatives

The utility company serving the project site conducts final verification before granting Permission to Operate. Each utility has different interconnection requirements and commissioning processes. Utilities rely on local AHJ inspectors or their own field engineers to verify that the system was installed according to code and meets the design submission requirements.

Third-Party Inspectors

Independent inspection services provide quality assurance for solar array owners, operators, and installers. Third-party inspectors offer unbiased assessments that can identify issues missed during internal reviews. These services are particularly valuable for large commercial projects, asset transfers, or situations where independent verification is required by financing or insurance providers. Standardized inspection checklists help ensure consistent evaluation across different inspectors.

NABCEP Certified Professionals

The North American Board of Certified Energy Practitioners offers several relevant certifications for commissioning personnel. The PV Commissioning & Maintenance Specialist (PVCMS) Board Certification highlights expertise in operations, maintenance, and commissioning, spotlighting ability to apply verification protocols, critically analyze systems, and implement preventive and corrective maintenance procedures. The PV System Inspector (PVSI) certification recognizes individuals highly knowledgeable about PV systems, applicable codes and ordinances, and assessing safety and operation of PV systems.

What Does A Commissioning Report Include?

A comprehensive commissioning report documents all inspections, tests, and verifications conducted on the solar PV installation. The report serves as permanent documentation of system condition at the time of commissioning and provides a baseline for future maintenance and performance monitoring.

General Compliance Documentation

The report begins with verification of adherence to applicable standards including IEC 62446, NEC requirements, and OSHA safety procedures. This section confirms that the installation meets all regulatory requirements and follows manufacturer specifications for all equipment. Reviewing equipment specifications ensures components match approved design documents.

Visual Inspection Results

Visual inspection checks the physical condition of components and alignment with design plans. Inspectors examine the overall installation for neat and professional workmanship, verifying that all components match project drawings and specifications. Visual assessment identifies visible defects such as scratches, discoloration, or damage on modules, as well as any abnormalities in framing, glass, junction boxes, and wiring. The visual assessment protocols provide detailed inspection procedures for this evaluation.

Module Installation Verification

This section verifies module alignment and torque requirements per manufacturer specifications. Inspectors confirm that PV modules are physically installed per plans regarding number and layout. The inspection verifies that modules are in good condition with no broken glass or cells and that the array is optimized for performance. Documentation includes verification that modules are properly warranted and listed by appropriate testing laboratories. Proper structural engineering calculations ensure mounting systems can support the installed modules.

Electrical Connections Assessment

The report confirms wiring integrity, connector engagement, and proper cable organization throughout the system. Wire management verification is essential since installation deficiencies frequently involve low-hanging or poorly managed wires, improper splicing and terminations, extended bend radii, and incorrectly installed connectors. All of these issues can compromise both safety and performance if not identified and corrected. Proper wire routing plans help prevent these common deficiencies.

Labeling And Signage Verification

Proper labeling for PV systems is required by code to provide adequate warnings for hazards and facilitate maintenance and emergency response. The commissioning report ensures accuracy and presence of all required labels as per project plans. Common labeling issues include illegible or faded labels and those with incorrect values or missing hazard warnings. Labels must include information such as the location of disconnects, system voltages, and potential hazard warnings.

System Testing Results

Comprehensive system testing includes voltage, current, grounding, insulation resistance, and inverter performance verification. Testing documentation typically covers:

- String testing for electrical continuity – Verifies that each string of modules is properly connected and functioning, confirming all electrical connections are secure and current flows as designed.

- Open-circuit voltage (Voc) and short-circuit current (Isc) tests – Confirms expected values match manufacturer specifications and design calculations, measured under controlled conditions and compared against environmental factors.

- Insulation resistance and polarity checks – Verifies wiring insulation is intact and all connections have correct polarity, identifying defects that could lead to short circuits or ground faults.

- Ground continuity and resistance validation – Ensures the grounding system provides adequate protection, safeguarding installers, inspectors, contractors, and occupants from electrical shock risk.

- Inverter performance testing – Verifies correct operation and grid interconnection functionality, including anti-islanding verification to confirm proper disconnect during utility outages.

System Performance Verification

The final section verifies that operational conditions meet performance benchmarks. A model calculates expected power or energy production based on equipment specifications and assumed energy losses at each point in the system. This calculation is adjusted based on environmental conditions measured during the test period, primarily available sunlight and module temperature. Comparing theoretical expected output with actual measured output produces a Performance Ratio used to assess overall system performance. Understanding PV system fundamentals helps interpret these performance metrics.

Common Deficiencies Found During Commissioning

Understanding common installation deficiencies helps installers prevent issues and helps system owners know what to expect during the commissioning process.

Wire Management Issues

Wire management failures represent one of the most frequently identified deficiencies during commissioning inspections. Common findings include cables that are not properly secured, improper splicing and terminations, conductors exceeding recommended bend radii, and incorrectly installed connectors. These issues can compromise both safety and system performance if not corrected.

Grounding Deficiencies

Systems that do not adhere to grounding standards present significant safety risks. Common grounding issues include improper conductor identification, disconnected wiring, and inadequate module or racking grounding. These deficiencies impact system performance and can put personnel at risk of electric shock.

Labeling Problems

Improper labeling can create complications for maintenance technicians and first responders. Inspectors frequently encounter labels that are illegible, faded, positioned incorrectly, or contain incorrect values. Missing hazard warnings represent a particularly serious deficiency that must be corrected before system operation.

Component And Enclosure Issues

Degraded enclosures and compromised connections can lead to vulnerabilities and decreased system performance, safety, and longevity. Components such as enclosures, penetrations, safety anchors, and conduit connections all help ensure reliability and lifespan of PV systems. The weather vulnerabilities guide details how environmental factors affect system components.

Module Defects

While less common with proper equipment procurement, module defects including micro-cracks, hot spots, cell damage, and junction box issues can impact system performance. Thermal imaging during commissioning can identify modules operating at abnormal temperatures, indicating potential defects that require attention.

Preparing For A Successful Commissioning Inspection

Proper preparation significantly improves the likelihood of passing inspection on the first attempt. Before scheduling, installers should ensure all documentation is ready, including as-built drawings, equipment datasheets, string maps, and calibration certificates for testing instruments. The installation should present a professional appearance with all labels correctly placed and legible, temporary construction items removed, and the work area clean. Conducting a thorough self-inspection using a detailed checklist helps identify and correct issues proactively before requesting official review. The federal solar procurement guide provides additional preparation recommendations.

Conclusion

Solar PV commissioning represents a critical quality assurance step that protects system owners, installers, and the broader electrical grid. Through systematic visual inspections, electrical testing, and performance verification, commissioning ensures that every installation operates safely and efficiently from day one. The documentation generated during this process serves as a permanent record of system condition, supporting warranty claims, insurance requirements, and future maintenance activities. Following established O&M best practices extends these benefits throughout the system lifecycle.

As the solar industry continues to grow and evolve, commissioning standards have become increasingly rigorous. The 2023 NEC updates, IEC 62446 requirements, and OSHA safety procedures all establish clear expectations for what constitutes a properly commissioned system. Meeting these standards requires expertise in electrical codes, testing procedures, and documentation requirements. For off-grid solar systems, commissioning remains equally important even without utility interconnection requirements.

Solar Permit Solutions provides comprehensive permit design services, engineering stamps, and interconnection support across all 50 states. Our experienced team helps ensure that projects meet all applicable requirements for successful commissioning and utility interconnection approval. Explore our solar blog for additional resources, or contact us today to learn how expert permit design and engineering support can help optimize solar projects for long-term reliability and success.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Final inspection typically refers to the AHJ verification that the installation meets local codes and regulations. Commissioning is a broader process that includes comprehensive testing, performance verification, and documentation that goes beyond basic code compliance to ensure optimal system operation.

The commissioning timeline varies based on system size and complexity. Residential systems may be commissioned in a single day, while large commercial installations may require several days of testing and documentation. The overall timeline from installation completion to Permission to Operate depends on local AHJ and utility scheduling.

If deficiencies are identified during commissioning, the installer must correct the issues and schedule re-inspection. Common deficiencies like labeling errors or minor wire management issues can often be corrected quickly. More significant issues such as grounding deficiencies or component failures may require more extensive rework before the system can be approved for operation.

Yes, some form of commissioning is required for all grid-connected solar installations. Local governments require permit inspections, and utilities require verification before granting interconnection approval. The scope and formality of commissioning documentation may vary based on system size and local requirements, but the fundamental verification process applies to all installations.

Most PV systems are contractually obligated to undergo inspection once or twice per year after initial commissioning. Regular inspections help identify performance degradation, equipment issues, or safety concerns that develop over time. Asset transfers also typically require inspection to verify system condition for the new owner.

Commissioning technicians typically use specialized equipment including insulation resistance testers rated for 1000V or higher, digital multimeters with CAT III ratings, clamp meters for current measurements, irradiance meters to measure sunlight intensity, and temperature probes for module temperature readings. All testing instruments should have current calibration certificates to ensure accurate measurements.

Qualified commissioning personnel may include licensed electricians with solar experience, certified professionals such as PV Installation Professionals or PV Commissioning and Maintenance Specialists, third-party inspection services, or trained technicians employed by the installation company. Local AHJ inspectors and utility representatives also conduct their own verification as part of the interconnection approval process.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

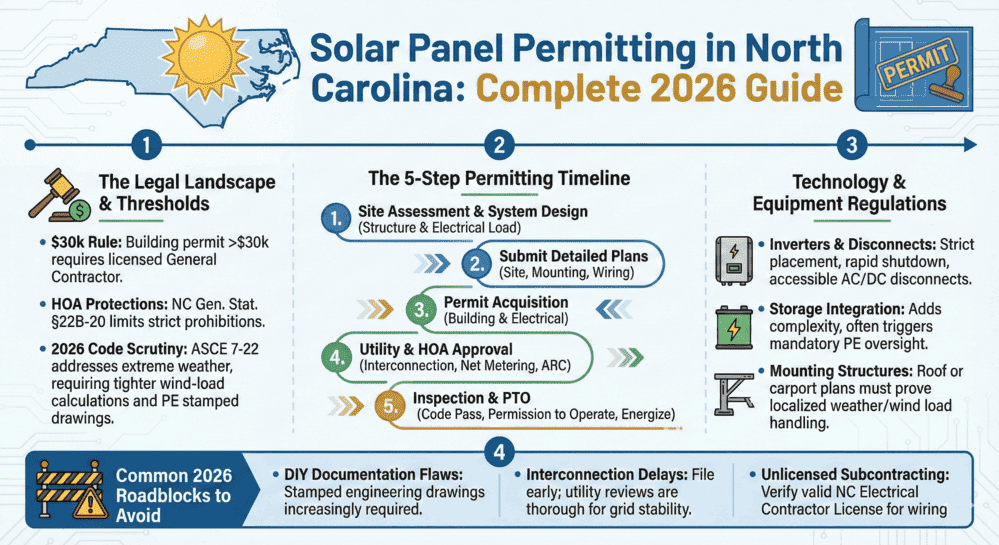

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...