Solar PV grounding systems require specific equipment to meet National Electrical Code (NEC) safety standards under sections 690.41 through 690.47. All PV circuits exceeding 30 volts or 8 amperes must have ground-fault protection devices installed. Equipment grounding conductors (EGC) and grounding electrode conductors (GEC) use copper wire only, with aluminum conductors prohibited for GEC applications.

Required grounding equipment includes copper-clad ground rods (5/8 inch or 3/4 inch diameter, 8-10 foot length), grounding clamps, UL2703 certified bonding products, and listed terminal bars. Ground rod spacing requires minimum 6 feet separation between electrodes. Conductor sizing follows NEC Tables 250.66 for GEC and 250.122 for EGC based on overcurrent protection device ratings.

Modern solar installations use functionally grounded inverters with integrated ground-fault protection certified to UL1741 standards. Module mounting systems need UL2703 listed bonding hardware including WEEB devices, grounding clips, and rail connectors. This guide covers essential grounding product specifications for NEC-compliant residential and commercial solar installations across all 50 states.

Essential Grounding Equipment For Solar PV Systems

Main Bonding Jumpers And Equipment Grounding Conductors

Ground fault current requires an effective return path to its source through proper equipment grounding conductors (EGC). Installing a main bonding jumper (MBJ) connects the EGC to the supply neutral at a single location only. Wire-type EGC products ranging from 14 AWG to 2 AWG copper conductors serve most residential installations, while larger commercial systems may require 1/0 AWG or larger grounding wire. This configuration applies to solidly grounded systems and prevents dangerous objectionable current conditions.

Listed Grounding Connectors And Terminal Bars

All grounding and bonding connections for equipment grounding conductors (EGC), grounding electrode conductors (GEC), and bonding jumpers at module mounting points must utilize listed devices or systems. Required products include UL-listed grounding terminal bars, bonding lugs, wire connectors, compression connectors, and mechanical lugs designed specifically for grounding applications. Ground bus bars with multiple terminal positions allow efficient connection of multiple grounding conductors at service panels and combiner boxes.

Grounding Busbars And Bonding Equipment Installation

Best practice requires connecting the main bonding jumper (MBJ) and grounding electrode conductor (GEC) at a common location using a grounding busbar within the main disconnect or distribution panel of a residential or commercial facility. Grounding busbars feature multiple terminal positions with set screws or compression hardware to secure copper conductors.

Connecting neutral to the EGC at multiple locations creates objectionable current. This problematic current flow occurs when multiple return paths allow current to travel back to the source through the grounding conductor (EGC) or equipment body during normal operation without any fault condition present. Multiple main bonding jumpers cause this issue.

Grounding Electrode Products And Installation Requirements

NEC sections 250.50 and 250.52 outline grounding electrode system requirements. Installing grounding electrodes below the permanent moisture level in the earth yields optimal results. Available grounding electrode products include:

i) Metal Underground Water Pipe Connections: Grounding clamps designed for underground metal water pipes maintaining direct earth contact for 10 feet or more. Bronze or copper water pipe grounding clamps with UL listing ensure proper bonding to metallic water service.

ii) Metal In-Ground Support Structure Bonding: Ground rods or direct bonding to metal support structure(s) maintaining direct earth contact vertically for 10 feet or more. Grounding lugs and bonding hardware connect racking systems to the grounding system.

iii) Concrete-Encased Electrodes (Ufer Ground): Rebar tie wire and cadweld connections bond electrically conductive steel reinforcing bars measuring at least 1/2 inch diameter and 20 feet length, or bare copper conductor sized 4 AWG minimum with 20 feet or greater length. Exothermic welding kits or listed compression connectors attach grounding conductors to rebar, with all components encased at least 2 inches deep in concrete.

iv) Ground Ring Products: Bare copper conductor measuring at least 2 AWG with minimum 20 feet length buried in earth forming a continuous ring. Irreversible compression connectors or exothermic welds join ring sections to create continuous grounding loops around structures.

v) Grounding Rod Systems: The most frequently utilized grounding electrode type. Copper-clad steel ground rods measuring 5/8 inch or 3/4 inch diameter with 8 foot or 10 foot lengths drive into earth. Ground rod clamps (acorn clamps, bolt-type clamps, or direct burial clamps) attach grounding electrode conductors to rod tops. Some installations require ground rod driving tools and extension couplings for deeper installation.

vi) Plate Electrode Products: Bare or electrically conductive coated iron or steel plates measuring at least 1/4 inch thickness, or solid uncoated copper plates measuring at least 0.06 inch thickness, featuring 2 square feet of exposed surface area. Grounding plates require bonding lugs or exothermic connections for GEC attachment.

Maintaining Proper Separation Between Grounding Electrodes

Supplemental grounding electrodes or rods require separation of at least 6 feet from the main grounding electrode.

Grounding Electrode Conductor Material Requirements

Copper conductors serve as the only permitted material for grounding electrode conductors (GEC). Bare copper wire, green insulated copper wire, or green/yellow striped copper wire products in sizes from 8 AWG through 3/0 AWG meet most residential and commercial solar applications. Aluminum grounding electrode conductors are prohibited.

Grounding Electrode Conductor Sizing And Products

NEC section 250.66 and Table 250.66 establish GEC sizing requirements. The GEC size depends on the largest ungrounded current-carrying conductor size in the system. Common GEC wire sizes include 8 AWG, 6 AWG, 4 AWG, 2 AWG, and 1/0 AWG bare or insulated copper conductors. Larger commercial installations may require 2/0 AWG or 3/0 AWG grounding electrode conductors.

Conduit And Protection Products For Grounding Electrode Conductors

GEC conductors smaller than 6 AWG must have protection through metal conduit, intermediate metal conduit (IMC), or PVC conduit products. Schedule 40 PVC conduit, rigid metal conduit (RMC), or IMC in 1/2 inch, 3/4 inch, or 1 inch trade sizes protect smaller grounding conductors from physical damage.

GEC conductors sized 6 AWG or larger facing exposure to physical damage also require conduit protection. Conduit straps, hangers, and mounting hardware secure protective raceways. Splicing the GEC is prohibited except through permitted methods using irreversible compression connectors or exothermic welding.

Bonding Hardware For Multiple Building Grounding Systems

Multiple buildings or structures with individual grounding systems or GECs must connect at a common location using grounding busbars, intersystem bonding terminals, or bonding bridges and eventually tie into a common grounding electrode.

Copper bonding jumpers, grounding busbars with multiple positions, and listed bonding hardware create these connections. Intersystem bonding terminals provide dedicated connection points for multiple grounding electrode conductors.

Equipment Grounding Conductors For Fixed Equipment

Exposed metal components of fixed equipment with potential to become energized must connect to the circuit equipment grounding conductor. Green insulated copper wire, bare copper wire, or equipment grounding wire in appropriate AWG sizes based on circuit protection creates these connections.

Grounding lugs, ring terminals, and compression connectors attach EGC wires to equipment enclosures and junction boxes. Solar Permit Solutions provides comprehensive grounding equipment specifications for residential and commercial solar projects.

Equipment Grounding Conductor Products And Wiring Methods

NEC section 250.118 identifies acceptable EGC types including wire-type conductors (insulated or bare copper in green or green/yellow), rigid metal conduit (RMC), intermediate metal conduit (IMC), electrical metallic tubing (EMT), or metal-clad cable (MC cable) components.

Flexible metal conduit and liquidtight flexible conduit also serve as equipment grounding conductors when properly bonded. Grounding bushings with bonding jumpers connect metallic raceways to equipment grounding systems.

Equipment Grounding Conductor Wire Sizing

NEC section 250.122 and Table 250.122 determine EGC sizing requirements. The EGC size depends on the overcurrent protection device (OCPD) rating in the PV circuit(s), though it need not exceed the current-carrying circuit conductor size.

Common EGC wire products include 14 AWG for 15A circuits, 12 AWG for 20A circuits, 10 AWG for 30A circuits, 8 AWG for 40-60A circuits, and 6 AWG for 100A circuits. When current conductor size increases to accommodate voltage drop, EGC size does not require corresponding increases, except as dictated by OCPD sizing and Table 250.122.

Raceway And Cable Armor Protection For Equipment Grounding Conductors

EGC conductors smaller than 6 AWG require protection from physical damage through raceway or cable armor installation. EMT (electrical metallic tubing), flexible metal conduit, MC cable armor, or PVC conduit products protect small gauge grounding wires.

These conductors must run alongside circuit or current-carrying conductors in the same raceway or cable when extending beyond the PV array vicinity. Cable ties, conduit straps, and mounting clips secure protected grounding conductors.

Functionally Grounded Inverter Equipment And Grounding Points

Modern installations typically employ functionally grounded inverters or PV arrays that lack isolation from the grounded output circuit of the inverter. String inverters, microinverters, and central inverters with integrated grounding systems provide built-in grounding points.

This configuration allows the PV circuit EGC to connect directly to the grounding point supplied by the inverter using listed grounding lugs or terminal blocks, eliminating separate DC grounding systems. The inverter grounding point connects onward to the residential facility or building grounding system through copper bonding jumpers and grounding electrode conductors.

Ground-Fault Protection Device Products And Integration

PV circuits exceeding 30V or 8A require ground-fault protection device (GFPD) installation. Contemporary string inverters, microinverters, and central inverters generally include built-in ground-fault detection and interruption circuitry. Standalone ground-fault detector-interrupter (GFDI) units provide protection for charge controllers and inverters lacking integrated protection.

All GFPD equipment must carry proper UL listing for PV ground-fault protection applications. Ground-fault protection devices shall disconnect faulted circuits from remaining circuits and halt inverter output power supply. Inverters should carry UL1741 listing which includes GFPD functionality testing and certification.

Ground-Fault Protection Device Installation Exceptions

Ground-fault protection devices are not mandatory for PV circuits installed off buildings when those circuits are solidly grounded and have no more than two PV circuits connected in parallel. These exempt systems, including some off-grid installations, still require proper grounding electrode products, ground rods with clamps, grounding electrode conductors, and bonding hardware for code compliance.

UL2703 Listed Bonding Products For PV Arrays

Exposed metal parts, equipment, or supporting structures in the PV circuit with potential to become energized must connect to the grounding system or EGC following NEC sections 250.104, 250.134, and 250.136. Devices and equipment supporting or mounting PV modules require UL2703 listing, labeling, and identification for bonding to the grounding system. UL2703 certified bonding products include:

- Module grounding clips and bonding jumpers

- Rail bonding attachments and WEEB (wire equipment electrode bonding) devices

- Grounding washers and bonding hardware

- Lay-in lugs and module frame clamps

- Racking system bonding connectors

- Ground lugs for mounting rails

Components listed to UL2703 standards reduce installation time, ensure adequate bonding strength, and provide reliable electrical connections for the system lifespan. These products create continuous grounding paths from module frames through racking systems to the equipment grounding conductor, essential for both residential and utility-scale solar projects.

Important Note: Lightning protection systems and associated grounding systems require design compliance with NFPA 780 as specified in NEC section 250.106.

Conclusion

Selecting proper grounding and bonding equipment stands as a critical safety requirement for every solar PV installation. Specifying the correct grounding products including ground rods, grounding clamps, bonding hardware, conductor sizes, and protection devices protects both personnel and equipment while ensuring long-term system reliability.

Solar professionals must recognize that grounding equipment serves multiple essential functions: providing safe fault current paths through equipment grounding conductors, preventing equipment damage with proper bonding products, reducing fire hazards through ground-fault protection devices, and protecting against electrical shock with properly sized grounding electrode systems.

The complexity of grounding equipment selection demands careful attention to conductor sizing, electrode product selection, connection hardware, and protection device implementation. Each grounding component within the system plays a specific role in maintaining electrical safety.

From selecting copper-clad ground rods with appropriate diameter and length to properly sizing equipment grounding conductor wire based on overcurrent protection devices, every product specification impacts overall system safety and code compliance.

Modern solar installations benefit from functionally grounded inverter equipment that simplifies DC grounding requirements while maintaining robust protection. Ground-fault protection devices integrated into contemporary inverters provide automatic fault detection and disconnection without adding external GFPD equipment.

However, installers must verify that all grounding components carry proper listings and certifications, particularly UL1741 for inverters with integrated ground-fault protection and UL2703 for module mounting bonding components, grounding clips, WEEB devices, and racking system grounding hardware.

Success in solar PV grounding equipment selection requires studying the complete NEC requirements alongside manufacturer specifications for grounding products. Sections 690.41 through 690.47 work in conjunction with Article 250 to establish comprehensive grounding equipment standards.

Solar professionals should treat this guide as an introduction to essential grounding products while consulting the full NEC text and equipment manufacturer installation instructions for detailed specifications. For professional solar design services or questions about grounding equipment specifications, contact our team for expert guidance on NEC-compliant installations.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

FAQs

Grounding electrode conductors (GEC) connect the electrical system to the earth through grounding electrodes like ground rods, establishing a reference to ground. GEC products include bare or green insulated copper conductors attached to ground rods, plates, or other electrodes.

The EGC size depends on the overcurrent protection device rating, while the GEC size depends on the largest ungrounded current-carrying conductor in the system. Both serve distinct safety functions and require different product specifications.

The NEC requires a single main bonding jumper connection to prevent this dangerous condition, which can cause equipment malfunction, corrosion, and potential shock hazards.

Copper conductors must be used for all grounding electrode conductor applications to ensure long-term reliability and maintain effective grounding system performance throughout the installation lifespan.

All other PV circuits exceeding 30 volts or 8 amperes require ground-fault protection devices. Most modern inverters include built-in ground-fault protection as a standard safety feature, automatically disconnecting faulted circuits and stopping power output when faults are detected.

This spacing requirement prevents the grounding electrodes from interfering with each other’s effectiveness and ensures that each rod or electrode contacts undisturbed earth with adequate resistance characteristics. Proper separation maintains the integrity of the overall grounding electrode system and helps achieve the required grounding resistance for the installation.

Bonding jumpers or continuous grounding electrode conductors connect multiple rods together.

However, the EGC cannot be smaller than required by the OCPD rating and need not be larger than the circuit conductors themselves. This provision prevents unnecessary oversizing while maintaining adequate fault current carrying capacity.

UL2703 certified grounding products include module bonding clips, WEEB (wire equipment electrode bonding) devices, grounding washers, lay-in lugs, rail bonding attachments, and specialized grounding hardware. These listed bonding components ensure proper electrical connection between module frames and racking rails, reduce installation time compared to drilling and tapping methods, and provide the required bonding strength for long-term system safety and performance.

Installing UL2703 products creates continuous low-resistance grounding paths from every module frame through the mounting system to the equipment grounding conductor. Proper installation by qualified professionals minimizes DIY installation risks and ensures code compliance. For more solar installation guidance, visit our solar blog.

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Equipment grounding conductors (EGC) provide a low-impedance path for fault current to return to the source during ground faults, protecting people and equipment. EGC products include green insulated copper wire, bare copper wire, metal conduit, or MC cable armor. Grounding electrode conductors (GEC) connect the electrical system to the earth through grounding electrodes like ground rods, establishing a reference to ground. GEC products include bare or green insulated copper conductors attached to ground rods, plates, or other electrodes. The EGC size depends on the overcurrent protection device rating, while the GEC size depends on the largest ungrounded current-carrying conductor in the system. Both serve distinct safety functions and require different product specifications.

Connecting neutral to the EGC at multiple locations creates objectionable current, where normal operating current flows through grounding conductors and equipment bodies instead of only returning through the neutral conductor. This occurs because electricity follows all available paths, and multiple bonding points create parallel return paths. The NEC requires a single main bonding jumper connection to prevent this dangerous condition, which can cause equipment malfunction, corrosion, and potential shock hazards.

No, the NEC specifically prohibits aluminum conductors from serving as grounding electrode conductors (GEC). This restriction exists because aluminum corrodes more readily when in contact with earth and moisture, compromising the grounding system integrity over time. Copper conductors must be used for all grounding electrode conductor applications to ensure long-term reliability and maintain effective grounding system performance throughout the installation lifespan.

Ground-fault protection devices are not mandatory for PV circuits that meet three specific conditions: the circuit is not installed on or in a building, the system is solidly grounded, and no more than two PV circuits are connected in parallel. All other PV circuits exceeding 30 volts or 8 amperes require ground-fault protection devices. Most modern inverters include built-in ground-fault protection as a standard safety feature, automatically disconnecting faulted circuits and stopping power output when faults are detected.

Supplemental grounding electrodes or rods must maintain separation of at least 6 feet from the main grounding electrode. When installing multiple 5/8 inch or 3/4 inch diameter copper-clad ground rods, drive them at least 6 feet apart measuring from rod center to rod center. This spacing requirement prevents the grounding electrodes from interfering with each other's effectiveness and ensures that each rod or electrode contacts undisturbed earth with adequate resistance characteristics. Proper separation maintains the integrity of the overall grounding electrode system and helps achieve the required grounding resistance for the installation. Bonding jumpers or continuous grounding electrode conductors connect multiple rods together.

When current-carrying conductors are increased in size to compensate for voltage drop, the equipment grounding conductor does not require proportional upsizing. The EGC size remains based on the overcurrent protection device rating according to NEC Table 250.122, not the actual conductor size. However, the EGC cannot be smaller than required by the OCPD rating and need not be larger than the circuit conductors themselves. This provision prevents unnecessary oversizing while maintaining adequate fault current carrying capacity.

Yes, exposed metal parts, equipment, and supporting structures in the PV circuit that are likely to become energized must connect to the grounding system or equipment grounding conductor. All mounting devices and equipment supporting PV modules must be listed, labeled, and identified for bonding purposes in accordance with UL2703 standards. UL2703 certified grounding products include module bonding clips, WEEB (wire equipment electrode bonding) devices, grounding washers, lay-in lugs, rail bonding attachments, and specialized grounding hardware. These listed bonding components ensure proper electrical connection between module frames and racking rails, reduce installation time compared to drilling and tapping methods, and provide the required bonding strength for long-term system safety and performance. Installing UL2703 products creates continuous low-resistance grounding paths from every module frame through the mounting system to the equipment grounding conductor.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

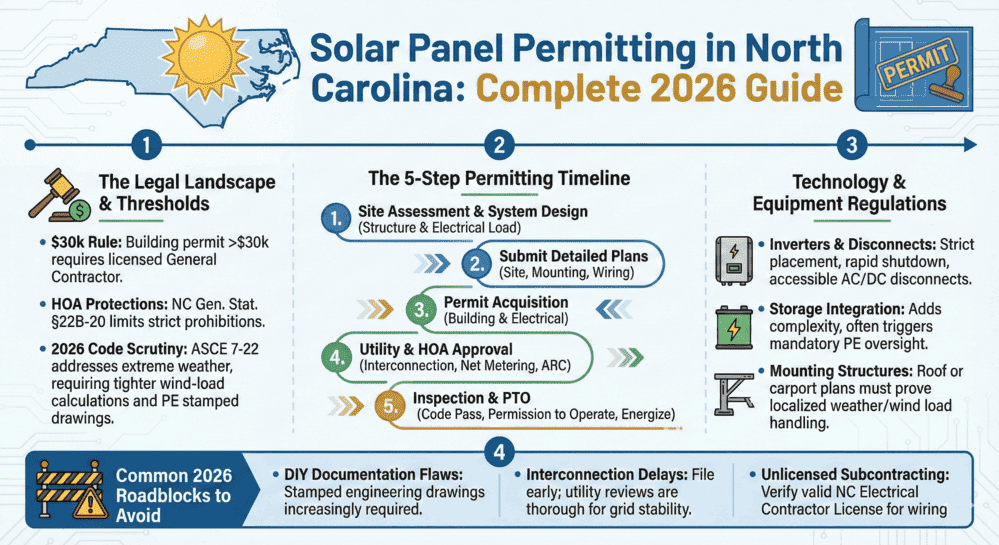

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...