Quick Answer: Use junction boxes for small residential solar systems with 3 or fewer strings and short wire runs. Use combiner boxes for systems with 4+ strings, commercial installations, or when NEC 690.9 overcurrent protection is required.

Key Differences:

- Junction boxes provide basic wire consolidation without overcurrent protection, costing less but offering limited safety features

- Combiner boxes include integrated fuses/breakers, surge protection, and disconnect switches for full NEC compliance

- Code requirement threshold: Systems exceeding 3-4 strings per inverter input typically require combiner boxes

- Cost vs. compliance: Junction boxes save upfront costs but may fail inspection on larger systems

When to Choose Each:

- Junction Box: ≤3 strings, short DC runs (<50 feet), inverter has built-in string fusing

- Combiner Box: 4+ strings, long wire runs (>50-75 feet), commercial/utility-scale projects, AHJ requires OCPD

Critical NEC Requirements:

- NEC 690.9(A) mandates overcurrent protection for source circuits

- NEC 690.13 requires disconnecting means (built into combiner boxes)

- NEC 690.15 establishes safe servicing isolation protocols

DC aggregation stands as a fundamental component in every photovoltaic installation, streamlining wire management, reducing voltage losses, and maintaining electrical code standards. Among the most frequently asked design questions in solar engineering: Which aggregation method serves your project better, a combiner box or a junction box?

This guide examines both approaches and clarifies when each solution delivers optimal results.

Understanding DC Aggregation in Solar Systems

DC aggregation describes the process of consolidating multiple string outputs from photovoltaic modules before they reach the inverter input.

Two primary methods accomplish this task:

Junction Box (JB): A basic enclosure designed for conductor splicing and circuit extension.

Combiner Box (CB): An engineered enclosure that consolidates circuits while incorporating overcurrent protection devices (fuses or circuit breakers), disconnect switches, and optional monitoring capabilities.

Junction Boxes: Streamlined Circuit Consolidation

Junction boxes serve specific installation scenarios:

- Compact arrays (generally 3 strings or fewer)

- Minimal DC conductor lengths

- Protected installation environments

Benefits:

- Economical component costs

- Straightforward installation procedures

- Minimal failure points when properly weatherproofed

Drawbacks:

- Absence of overcurrent protection devices (OCPD)

- Restricted troubleshooting accessibility

- Unsuitable for high-amperage applications or strict NEC 690.9 requirements

Optimal Applications:

- Residential installations with abbreviated wire runs

- Rooftop-mounted arrays where strings connect directly to inverter inputs

Combiner Boxes: Engineered Protection and Control

Combiner boxes address larger-scale installations and stringent safety requirements.

These units integrate fusing systems, circuit breakers, surge protection devices, and advanced monitoring features (including string-level current measurement).

Benefits:

- Built-in overcurrent protection (satisfies NEC 690.9 requirements)

- Simplified circuit isolation for maintenance procedures

- Decreased conduit requirements and wiring complexity

- Remote monitoring capabilities in upgraded models

Drawbacks:

- Elevated equipment and installation expenses

- Space allocation and weatherproofing considerations

- Thermal management requirements for proper ventilation

Optimal Applications:

- Commercial and utility-grade installations

- Systems combining 3-4+ strings per maximum power point tracker

- Projects where OCPD or surge protection devices are mandated by the Authority Having Jurisdiction or inverter specifications

National Electrical Code Compliance Standards

NEC 690.9(A): Mandates overcurrent protection for individual source circuits unless manufacturer documentation provides exemption.

NEC 690.13: Requires disconnecting mechanisms for PV source circuits, frequently incorporated within combiner box designs.

NEC 690.15: Establishes safe servicing isolation protocols, another factor favoring combiner boxes in larger applications.

Expert Insight: Verify whether your inverter includes integrated string fusing. When present, junction boxes may meet requirements, assuming conductor ampacity and routing satisfy NEC 310.15(B)(3) temperature correction factors.

Comparing System Requirements and Capabilities

Decision Framework: Projects exceeding 3-4 strings per inverter input, or those requiring fused inputs per AHJ requirements, demand combiner box installations.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Installation and Maintenance Best Practices

Environmental Protection: Specify IP65/NEMA 4X-rated enclosures for exterior installations.

Cable Management: Implement gland plates or conduit entry systems to prevent moisture infiltration.

Identification: Adhere to NEC 690.31(G). All DC enclosures require clear, permanent identification labels.

Fuse Selection: Utilize touch-safe fuses rated for 1000V/1500V DC applications with UL 2579 certification.

Hybrid Junction Solutions for Mid-Range Projects

Contemporary systems now feature “hybrid junction boxes” incorporating:

- Busbars for consolidating 2-3 string circuits

- Inline fusing for limited overcurrent protection

- Factory-wired connectors for rapid installation

These units bridge the gap for residential or light commercial projects requiring both installation efficiency and code compliance.

System-Specific Selection Guide

Making the Strategic Choice

Selecting between combiner boxes and junction boxes extends beyond budget considerations. This decision impacts compliance verification, system safety, and long-term serviceability.

As system capacity increases, basic junction box functionality typically transitions to the enhanced protection and features of combiner boxes.

Strategic aggregation design delivers:

- Accelerated permitting and approval processes

- Minimized maintenance liability

- Optimized, safer conductor layouts

Bottom Line: Effective DC aggregation strategy represents a critical design element, not an installation afterthought, forming the foundation of safe, serviceable photovoltaic systems.

Conclusion

Selecting the appropriate DC aggregation method represents more than a line item on your equipment list. It’s a fundamental decision that influences system safety, code compliance, and operational efficiency throughout your solar installation’s lifespan.

Junction boxes offer simplicity and cost savings for smaller residential projects where direct string-to-inverter connections make practical sense. They excel in straightforward applications with minimal string counts and short conductor runs. However, as your system scales or faces stricter regulatory requirements, the limitations of basic junction boxes become apparent.

Combiner boxes provide comprehensive protection, integrated safety features, and maintenance accessibility that larger commercial and utility-scale projects demand. While the upfront investment exceeds basic junction box costs, the benefits (faster permitting, simplified troubleshooting, enhanced safety protocols, and NEC compliance) deliver long-term value that justifies the expense.

The key lies in matching your aggregation strategy to your specific project parameters. Consider string count, conductor distances, Authority Having Jurisdiction requirements, inverter specifications, and future service needs when making this decision. A properly specified DC aggregation system doesn’t just meet code. It creates a foundation for reliable, maintainable solar production for decades to come.

Whether you choose the streamlined approach of a junction box or the robust capabilities of a combiner box, prioritize quality components, proper installation techniques, and strict adherence to National Electrical Code standards. Your DC aggregation choice today directly impacts system performance, safety margins, and maintenance costs tomorrow.

FAQs

What’s the difference between a hybrid junction box and a standard combiner box?

Hybrid junction boxes represent a middle-ground solution that incorporates limited overcurrent protection (typically inline fuses for 2-3 strings) within a compact enclosure, while standard combiner boxes offer comprehensive protection features including multiple circuit breakers or fuses, disconnect switches, surge protection devices, and monitoring capabilities for larger string counts. Hybrid units work well for small commercial or larger residential installations where you need some overcurrent protection without the full feature set and cost of industrial combiner boxes. Standard combiner boxes handle higher current loads, provide easier maintenance access, offer better thermal management, and accommodate future system expansions more effectively. Think of hybrid junction boxes as an upgrade path from basic junction boxes rather than a replacement for purpose-built combiner boxes in substantial installations.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

You can use a junction box for smaller residential systems (typically 3 strings or fewer) with short DC wire runs, provided your inverter includes built-in string fusing and your local Authority Having Jurisdiction doesn't mandate external overcurrent protection. However, junction boxes lack the safety features, overcurrent protection, and code compliance capabilities that combiner boxes provide. While junction boxes cost less initially, attempting to use them on larger systems or in jurisdictions requiring NEC 690.9 compliance will result in failed inspections and costly reinstallation. Always verify your inverter specifications and local code requirements before selecting a junction box to ensure you're not sacrificing safety and compliance for short-term savings.

Systems combining 4 or more strings per inverter input typically require combiner boxes to manage the increased current safely and meet code requirements. Additionally, any installation with long DC conductor runs (generally exceeding 50-75 feet), commercial or utility-scale projects, or systems where your local Authority Having Jurisdiction specifically mandates overcurrent protection devices will need combiner boxes regardless of string count. Even smaller systems may require combiner boxes if your inverter lacks integrated string fusing or if you're installing in an area with strict electrical code enforcement. The decision point isn't solely about system size. It's about combining code compliance, safety requirements, and system architecture into a comprehensive design strategy.

Combiner boxes require periodic inspections to ensure continued safe operation, though maintenance demands remain relatively minimal. Annual visual inspections should check for physical damage, moisture ingress, loose connections, and proper labeling integrity. Thermographic scanning every 2-3 years helps identify hot spots indicating failing fuses or loose terminations before they cause system failures. Fuse replacement occurs only when circuit faults occur or during troubleshooting procedures. The monitoring capabilities in advanced combiner boxes actually reduce maintenance needs by providing real-time alerts about string performance issues, allowing you to address problems proactively rather than through scheduled site visits. Proper installation with appropriate IP ratings and weatherproofing significantly extends service intervals and reduces maintenance requirements.

Hybrid junction boxes represent a middle-ground solution that incorporates limited overcurrent protection (typically inline fuses for 2-3 strings) within a compact enclosure, while standard combiner boxes offer comprehensive protection features including multiple circuit breakers or fuses, disconnect switches, surge protection devices, and monitoring capabilities for larger string counts. Hybrid units work well for small commercial or larger residential installations where you need some overcurrent protection without the full feature set and cost of industrial combiner boxes. Standard combiner boxes handle higher current loads, provide easier maintenance access, offer better thermal management, and accommodate future system expansions more effectively. Think of hybrid junction boxes as an upgrade path from basic junction boxes rather than a replacement for purpose-built combiner boxes in substantial installations.

Yes, you can retrofit a combiner box into an existing solar system, and this upgrade often makes sense when expanding your array, addressing code compliance issues, or improving system serviceability. The retrofit process involves replacing the existing junction box with an appropriately sized combiner box, installing overcurrent protection devices for each string circuit, updating labeling to meet current NEC requirements, and potentially upgrading conductors if ampacity calculations reveal undersized wiring. However, this modification requires pulling permits, scheduling electrical inspections, and temporarily shutting down your solar production during installation. The cost includes equipment, labor, and permitting fees, but many system owners find the improved safety, easier troubleshooting, and code compliance worth the investment, particularly when combined with other system upgrades or expansions. Always work with licensed solar contractors familiar with local code requirements when retrofitting DC aggregation components.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

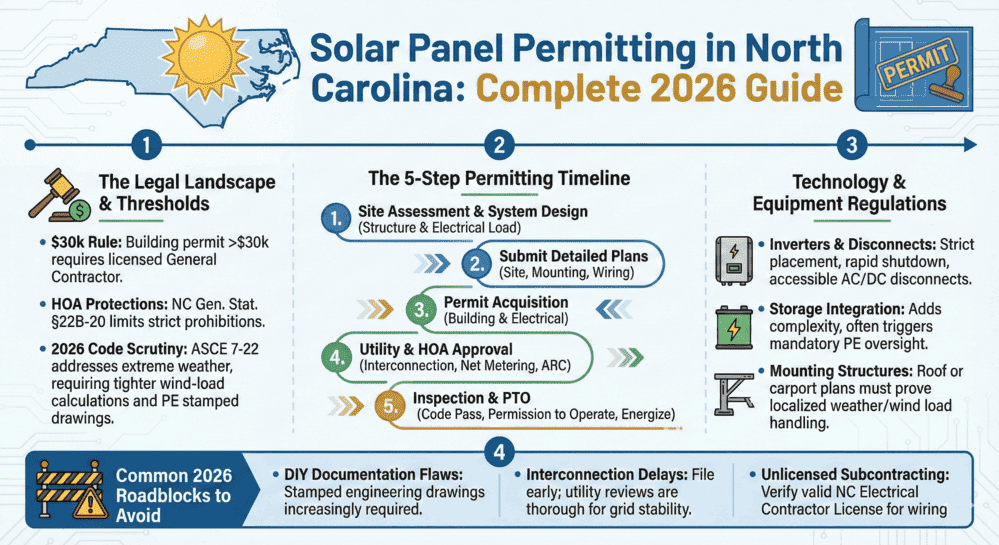

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...