Metal roof solar installations require specialized mounting solutions tailored to three primary roof types: standing seam, corrugated, and exposed fastener configurations. Each type demands specific clamps, brackets, and racking systems to ensure weatherproof, long-lasting photovoltaic arrays. Standing seam roofs allow non-penetrative mounting that eliminates leak risks, while corrugated and exposed fastener systems require penetrative attachments with proper sealing techniques.

The metal roofing market has expanded substantially, with residential adoption growing from 12% in 2019 to 17% in 2021. As of 2022, one-third of all commercial buildings in the United States utilize metal roofing due to three key advantages: exceptional durability lasting 40 to 70 years, lightweight construction requiring no structural reinforcement, and superior load-bearing capacity for solar equipment. These characteristics make metal roofs ideal foundations for solar energy systems, particularly since their lifespan nearly doubles that of typical photovoltaic installations.

Regional preferences influence metal roof selection significantly. The Southeastern United States, where metal roofing holds a 30% market share, predominantly features standing seam installations due to their superior wind resistance and interlocking capabilities. Metal panels connect through raised seams positioned several inches above the roof surface, creating a sleek profile that withstands severe weather conditions. In contrast, the Pacific Northwest and Rocky Mountain regions favor metal shingle designs that better suit their climate requirements and architectural preferences.

Commercial installations present diverse metal roofing applications influenced heavily by local building codes. Exposed fastener metal roofing, where metal panels attach directly to structural framing with visible fasteners, offers economical solutions common in agricultural and industrial facilities. Corrugated metal roofing provides another cost-effective option for large-scale storage and commercial buildings, utilizing textured rolling siding secured with penetrating fasteners. Each configuration requires distinct mounting approaches to maintain structural integrity and weatherproofing standards.

Insurance companies increasingly incentivize metal roofing installations because these systems withstand extreme weather and high temperatures for four to seven decades. Beyond exceptional durability, metal roofs accommodate both live and dead loads from solar installations without requiring deck reinforcement. Modern metal roofs often incorporate reflective coating technologies that reduce surface temperatures, directly improving solar panel efficiency by maintaining optimal operating conditions for photovoltaic modules.

Photovoltaic Array Attachment Methods For Standing Seam Surfaces

Standing seam metal roofs offer convenient solar installation without requiring drilled holes, minimizing leakage and damage risks. Numerous manufacturers have engineered specialized solutions for standing seam roofs where clamps attach to the vertical ribs along roof panel edges. Multiple manufacturers provide sturdy, non-penetrative clamps designed for straightforward installation and compatibility with various mounting systems. Several robust, watertight attachment options exist for standing seam metal roofs, offering cost-effective solutions that avoid roof penetration or ridge collapse risks. Industry-standard clamps have established reliable performance benchmarks over extended periods. Additional resources detail standing seam roof applications and innovative problem-solving approaches utilized by installation professionals.

Corrugated Panel Solar Racking Techniques

While standing seam roofs rank among the most solar-compatible options, specific mounting solutions exist for corrugated metal roofs. Specialized brackets designed for corrugated roofs accommodate pitched installations with rail-based systems. Stainless steel hanger bolts with sealing washers enable efficient and rapid anchoring into metal substructures. These corrugated solar fastening systems encompass multiple categories, including trapezoidal and sinusoidal roof configurations.

The principal challenge in mounting solar arrays on corrugated metal involves securing brackets through penetrative fasteners. The critical step involves applying proper sealants to cover penetrations, preventing water infiltration that could cause substantial roof damage. Factory-applied butyl sealants in bracket bases provide efficient installation solutions. However, verifying roof manufacturer warranty terms before installing solar on corrugated metal roofs remains essential, as penetrations may void certain warranties.

Mounting Strategies For Exposed Fastener Roof Configurations

Installation professionals access numerous options for exposed fastener metal roofs. Given their structural rigidity compared to standing seam metal roofs, exposed fastener systems experience reduced temperature expansion effects. Weatherproofing demands careful attention, particularly considering exposed fasteners’ susceptibility to environmental elements. Selecting corrosion-resistant sealants or weather-rated mounts proves essential for this roofing type. Exposed fastener metal roofs may require high-mount clamp solutions positioned above the water plane. Installers should evaluate all factors when designing solar arrays for exposed fastener metal roofs.

Various dependable options provide sturdy, long-lasting attachments for this roofing category. Trapezoidal clamps with high profiles create spacing between modules and metal roof panels. Multiple sizes accommodate different seam widths and dimensions. Another solution for exposed fastener metal roofs includes flexible mounting systems suitable for roofs of any slope or material. These waterproof, cost-effective options work on certain exposed fastener roofs without requiring pilot holes.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Essential Factors For Successful Metal Roof PV Integration

Metal roofs generally provide resilient options for residential and commercial property owners, though proper planning remains necessary to prevent future weather-related complications. Solar installers and roofing contractors must utilize certified sealants and attachments to protect client investments long-term. Professional guidance from Solar Permit Solutions ensures implementation of the safest, most economical installation approaches available. Connecting with experienced solar distributors provides access to comprehensive support for successful metal roof solar projects.

Conclusion

Metal roofing continues to prove itself as an outstanding foundation for solar energy systems across residential and commercial applications. The variety of mounting solutions available today ensures that regardless of roof type, whether standing seam, corrugated, or exposed fastener, installation professionals can execute secure and weatherproof photovoltaic installations. The key to success lies in understanding the unique characteristics of each metal roof configuration and selecting appropriate hardware that balances structural integrity, weatherproofing requirements, and long-term durability.

As the metal roofing market expands and solar adoption accelerates, the intersection of these two technologies creates opportunities for property owners to maximize their investments. By leveraging non-penetrative mounting options where possible and employing proper waterproofing methods when penetrations are necessary, installers can deliver systems that protect both the solar array and the roof structure for decades to come. The combination of metal roofing’s exceptional lifespan and solar energy’s benefits positions these integrated systems as smart choices for forward-thinking property owners nationwide.

FAQs

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Metal roofs offer several advantages for solar installations, including exceptional durability lasting 40 to 70 years, lightweight construction that requires no additional structural reinforcement, and the ability to support solar system loads easily. Many modern metal roofs also feature reflective coatings that reduce surface temperatures, which can enhance solar panel efficiency. Additionally, certain metal roof types like standing seam allow for non-penetrative mounting solutions that eliminate leak risks.

Yes, solar panels can be installed on all major metal roof types, including standing seam, corrugated, and exposed fastener configurations. Each roof type requires specific mounting hardware and installation techniques. Standing seam roofs offer the easiest installation with non-penetrative clamps, while corrugated and exposed fastener roofs typically require penetrative mounting with proper sealing. The key is matching the appropriate racking system to the specific metal roof configuration.

This depends on the roof manufacturer and the installation method used. Standing seam installations using non-penetrative clamps typically do not affect roof warranties since they avoid drilling holes. However, corrugated and exposed fastener installations that require roof penetrations may void certain warranties. Always verify warranty terms with the roof manufacturer before proceeding with solar installation and ensure installers use approved mounting methods and sealants.

Preventing water infiltration requires using high-quality, corrosion-resistant sealants rated for outdoor exposure and metal roofing applications. Many mounting brackets come with factory-applied butyl sealants that provide reliable waterproofing. For exposed fastener roofs, consider high-mount clamp solutions that sit above the water plane. All penetrations should be sealed according to manufacturer specifications, and installers should use certified mounting hardware designed specifically for the roof type.

Metal roofs require different mounting approaches than asphalt shingles but often provide superior installation conditions. The primary considerations include selecting roof-specific clamps or brackets, accounting for thermal expansion in certain metal roof types, and ensuring proper weatherproofing at attachment points. Metal roofs typically offer advantages like greater load-bearing capacity, longer lifespan that matches or exceeds solar system life expectancy, and in some cases, the option for non-penetrative mounting that eliminates leak concerns entirely.

Temperature expansion primarily affects standing seam metal roofs, where panels can expand and contract with temperature changes. Proper mounting clamps for standing seam roofs are designed to accommodate this movement without compromising attachment integrity. Exposed fastener metal roofs demonstrate greater structural rigidity and experience less thermal expansion impact. Installation professionals must select hardware specifically engineered for each roof type to ensure long-term stability despite seasonal temperature fluctuations.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

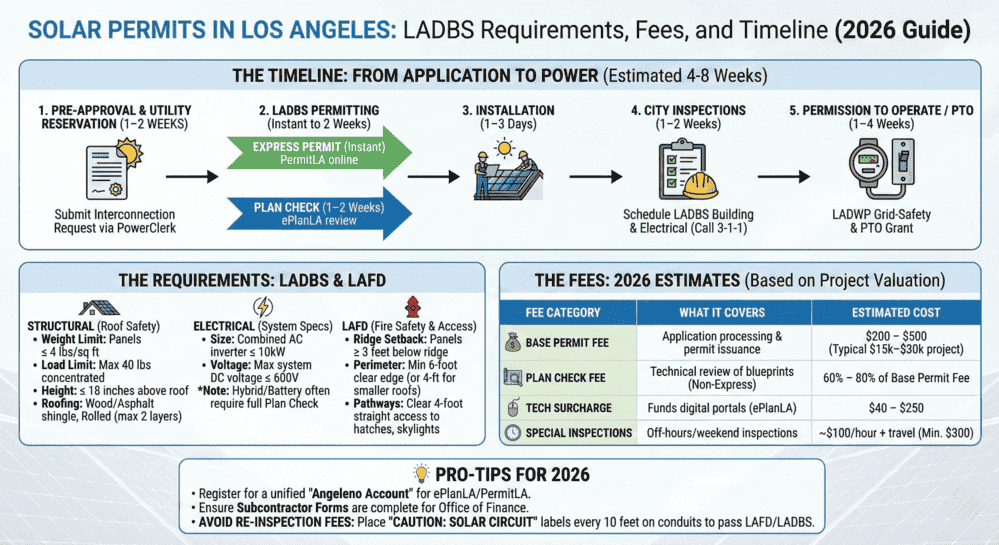

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...

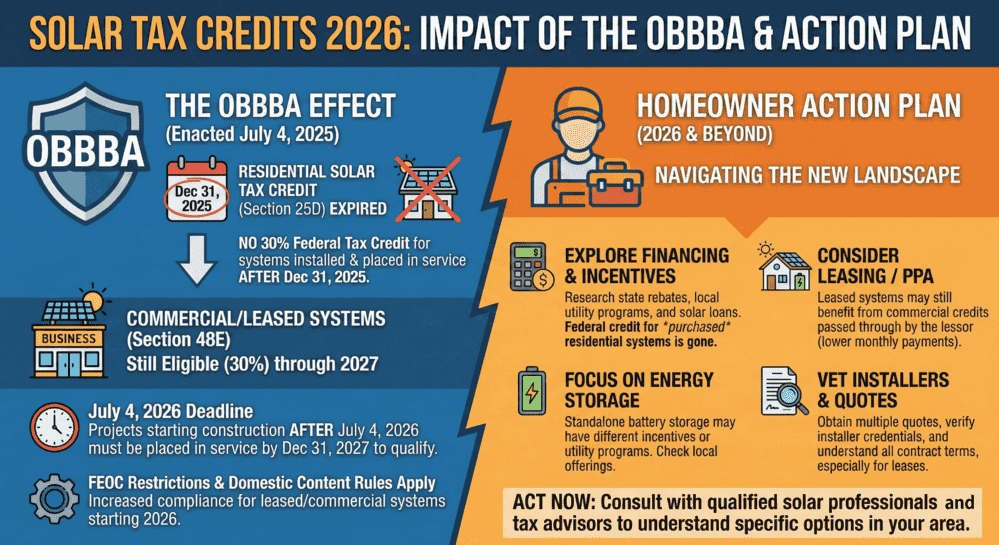

Solar Tax Credits 2026: What Changed After OBBBA and What Homeowners Can Do Now

Summary: The federal residential solar tax credit (Section 25D) expired December...

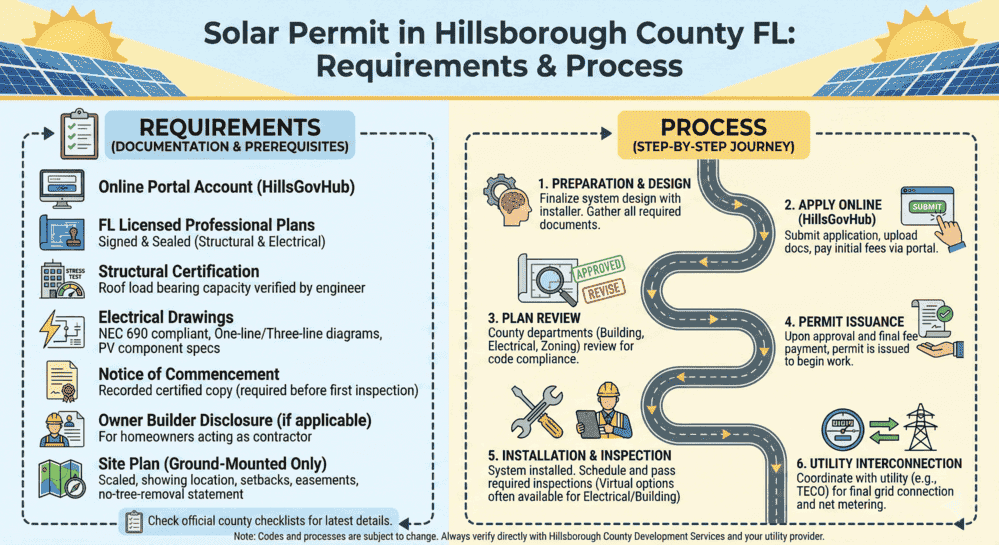

Solar Permit in Hillsborough County FL: Requirements & Process

Hillsborough County solar permits require either an Electrical Trade permit for ...