Understanding SPD Selection for Solar Power Systems

Selecting the right Surge Protective Device (SPD) for your solar power system involves matching voltage ratings to your system’s specifications, determining appropriate discharge current capacity, and ensuring strategic placement throughout your installation. SPDs protect photovoltaic systems from lightning strikes, grid-switching events, and induced surges that can damage inverters, charge controllers, and monitoring equipment, potentially causing thousands of dollars in losses or gradual component degradation over time.

Key SPD Selection Criteria:

SPD Types: Type 1 SPDs defend against direct lightning strikes at service entrance points (tested with 10/350 μs waveform), Type 2 SPDs protect against induced surges at distribution panels (tested with 8/20 μs waveform, most common for residential solar), and Type 3 SPDs provide fine protection for sensitive terminal equipment. Most installations require combinations of these types for comprehensive coverage.

Voltage Requirements: Choose SPDs with Maximum Continuous Operating Voltage (MCOV) at least 10% above your system’s maximum open-circuit voltage, for example, 660V DC MCOV for a 600V DC system. The Voltage Protection Level (Up) should be at least 20% lower than equipment tolerance, typically below 2.5-4 kV for PV inverters.

Current Capacity: Type 2 SPDs should have Nominal Discharge Current (In) ratings of 10-20kA or higher, with Maximum Discharge Current (Imax) typically ranging from 40 to 80 kA. High-lightning regions require higher ratings to handle frequent surge events.

Strategic Placement: Follow the “<10 Meter Rule"; if DC cable length exceeds 10 meters, install two sets of SPDs (one near the PV array in combiner boxes and another at the inverter input). For shorter runs, a single set at the inverter DC input suffices. AC side protection requires SPDs at the grid interconnection point, inverter AC output, and distribution panels.

Installation Best Practices: Keep SPD connection leads under 0.5 meters (never exceeding 1 meter), use minimum 6 mm² copper conductors for Type 2 SPDs (16 mm² for Type 1), and route cables together with equipotential bonding conductors to minimize induced overvoltages.

Compliance Standards: Verify SPDs meet IEC 61643-31 (photovoltaic applications), IEC 61643-32 (selection principles), UL 1449 (North American safety), IEC 62305 Series (lightning protection), and NEC Article 690.7(C) requirements.

This guide provides actionable steps for evaluating SPD types, calculating voltage requirements, assessing discharge capacity, determining optimal placement locations, and implementing proper installation techniques to protect your solar investment from electrical surge damage.

The Importance of SPD Protection for Your Photovoltaic Installation

Photovoltaic energy installations face heightened susceptibility to transient damage due to multiple factors:

- Exposed positioning: Photovoltaic arrays are commonly mounted in high, unprotected locations

- Long wiring distances: DC electrical cables can function as conductors for induced transients

- Delicate electronic components: Inverters, monitoring equipment, and control systems house susceptible elements

- Lightning susceptibility: Photovoltaic panel installations can become preferred routes for lightning discharge

In the absence of proper transient protection, one lightning discharge or utility-switching occurrence can result in substantial financial damage to your inverters, charge management devices, panels, and monitoring equipment. Even minor, recurring transients can deteriorate installation components gradually, diminishing performance and reducing service life.

Essential Considerations for Choosing the Appropriate Photovoltaic SPD

1. Comprehend SPD Classifications and Their Uses

SPDs are divided into three primary classifications, each addressing distinct protection requirements:

Type 1 SPDs:

- Applied for defense against direct lightning discharge

- Positioned at main service entry locations or grid connection points

- Validated with 10/350 μs impulse to manage high-energy transients

- Necessary in structures equipped with external lightning defense installations

- Generally utilize spark gap mechanisms

Type 2 SPDs:

- Deliver defense against induced transients and utility-switching occurrences

- Positioned at electrical distribution panels or secondary panels

- Validated with 8/20μs impulse

- Utilize Metal Oxide Varistor (MOV) mechanisms

- Most frequently employed classification in conventional photovoltaic installations

Type 3 SPDs:

- Deliver precision defense for delicate end-use equipment

- Positioned adjacent to particular electronic components

- Possess reduced discharge capability compared to Classifications 1 and 2

- Commonly applied for monitoring equipment and data transmission connections

For most residential and commercial solar systems, you’ll need a combination of SPD types for comprehensive protection. Type 1+2 combined SPDs are also available, which integrate the protective characteristics of both types into a single unit.

2. Evaluate Your System Voltage Requirements

One of the most critical selection criteria is matching the SPD’s voltage rating to your solar system’s requirements:

Maximum Continuous Operating Voltage (MCOV or Uc):

- DC-side SPDs must have MCOV ratings higher than your system’s maximum open-circuit voltage (Voc)

- Remember that cold temperatures increase PV array voltage

- A good rule of thumb: Select DC SPDs with MCOV at least 10% above maximum system Voc

- For example, a 600V DC system requires SPDs with MCOV of at least 660V DC

- AC side SPDs should exceed nominal system voltage by at least 25%

Using an SPD with insufficient MCOV will result in premature failure and potentially create fire hazards, as the device will see normal system voltage as a surge condition.

3. Check the Voltage Protection Level (Up)

The voltage protection level, or clamping voltage, indicates the maximum voltage that will reach your equipment during a surge:

- Lower Up values provide better protection for sensitive components

- The Up should be below the impulse withstand rating of your equipment

- For best protection, choose an SPD with Up at least 20% lower than equipment tolerance

- Typical PV inverters require Up values below 2.5-4 kV.

When comparing SPDs, a lower voltage protection level generally indicates superior protection, but must be balanced with other parameters.

4. Assess Required Discharge Current Capacity

Two important ratings determine an SPD’s ability to handle surge currents:

Nominal Discharge Current (In):

- Indicates how much surge current the SPD can handle repeatedly

- Higher values mean better durability for frequent surges

- For Type 2 SPDs in solar applications, look for In ratings of 10-20 kA or higher

Maximum Discharge Current (Imax):

- The highest single surge current the SPD can safely divert

- Type 2 devices typically range from 40 to 80 kA.

- Systems in high-lightning regions should use higher ratings

- Type 1 SPDs use Impulse Discharge Current (Iimp) rating instead

Balance these ratings based on your location’s lightning risk and system importance. Areas with frequent thunderstorms require higher ratings than locations with minimal lightning activity.

5. Consider Short Circuit Current Rating (SCCR)

The SCCR specifies the maximum prospective short-circuit current the SPD can safely handle if it fails:

- The SPD’s SCCR must be equal to or greater than the available fault current at its installation point

- This is a mandatory safety requirement in many electrical codes

- DC SPDs in high-voltage PV systems face significant challenges with fault current handling

- Some SPDs require external overcurrent protection devices to achieve their marked SCCR

6. Determine Optimal SPD Placement

Strategic placement of SPDs is crucial for effective solar system protection:

DC Side Placement Guidelines:

The “<10 Meter Rule" is widely adopted in the industry:

- If DC cable length is less than 10 meters: A single set of SPDs at the inverter DC input is generally sufficient

- If DC cable length exceeds 10 meters: Install two sets of SPDs, one near the PV array (in combiner boxes) and another at the inverter input

For larger systems, consider protection at these key points:

- Array level: Install SPDs at combiner boxes for distributed arrays

- Inverter DC input: Install SPDs immediately before inverter DC inputs

- String level: For systems with multiple strings, consider string-level protection

AC Side Placement:

- Grid interconnection point: Primary protection at main service panel

- Inverter AC output: Secondary protection near the inverter

- Distribution panels: Additional protection at sub-panels for larger systems

Also consider protection for communication and monitoring systems, which are often highly sensitive to surges.

7. Check Compliance with Relevant Standards

Verify that your selected SPDs comply with applicable standards:

- IEC 61643-31: Standard specifically for SPDs in photovoltaic applications

- IEC 61643-32: Selection and application principles for PV SPDs

- UL 1449: Safety standard for SPDs in North America

- IEC 62305 Series: Standards for lightning protection systems

- NEC Article 690.7(C): National Electrical Code requirements

Products meeting UL 1449 with Type 1 or Type 2 designation are generally accepted for PV applications in North America.

8. Evaluate Influence of External Lightning Protection

If your building has an external Lightning Protection System (LPS), you need to consider the “separation distance'” between it and your PV system:

- If separation distance can be maintained: Type 2 SPDs may be sufficient

- If separation distance cannot be maintained: Type 1 SPDs become mandatory

This is a fundamental design consideration that significantly impacts your SPD selection strategy.

9. Understand Your System’s Grounding Configuration

Different grounding configurations require specific SPD connection schemes:

DC Side Configurations:

- Functionally earthed: One DC pole connected to earth

- High-resistance earthed: DC pole connected to earth through resistance

- Unearthed/floating: Neither pole directly connected to earth

AC Side Configurations:

- TN-C, TN-S, TN-C-S systems

- TT systems

- IT systems

Each configuration requires a specific SPD connection scheme to ensure effective protection. For example, ungrounded (IT) PV systems often need SPDs with “Y-configurations” for comprehensive protection.

Installation Best Practices for Optimal SPD Performance

Minimize Connection Lead Lengths

The physical wiring of an SPD critically affects its effectiveness:

- Maintain connecting leads as brief as absolutely achievable

- Optimal total lead lengths should fall under 0.5 meters

- Never surpass 1 meter for total connection distance

- Prevent sharp bends in conductors as they elevate inductance

During rapid-rising transient currents, even brief lengths of connecting wire generate substantial inductive voltage drop. This adds directly to the SPD’s limiting voltage, potentially undermining defense.

Guarantee Proper Conductor Sizing

- For Type 2 SPDs, utilize minimum 6 mm² copper conductors for protective earth connections

- For Type 1 SPDs, utilize 16 mm² copper or larger for protective earth connections

- Live conductors should equal at least system wiring, if not larger

- Always adhere to manufacturer guidelines and applicable standards

Direct Cables Appropriately

- Direct AC, DC, and data cables together with their corresponding equipotential bonding conductors

- This minimizes the area of loops created by wiring, reducing induced over voltages

- Establish designated cable routes that minimize exposure to electromagnetic interference

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Maintenance Requirements for Long-Term Defense

Even the most effective SPDs possess a limited lifespan:

- Most quality SPDs possess a 10-15 year anticipated service life under standard conditions

- Visual indicators should be examined regularly for evidence of SPD activation or malfunction

- For critical installations, choose SPDs with remote monitoring capabilities

- Replace SPDs following major transient occurrences even if no external damage is apparent

- Create regular inspection schedules, particularly before storm seasons

Common SPD Selection Mistakes to Prevent

Prevent these frequent errors when selecting transient protection for your photovoltaic installation:

- Under sizing defense: Choosing SPDs with inadequate energy management capability

- Disregarding thermal performance: Neglecting to account for elevated temperatures in outdoor enclosures

- Neglecting coordination: Positioning mismatched SPDs that don’t appropriately coordinate energy dissipation

- Incomplete defense: Defending only the DC or AC side, creating vulnerabilities

- Using AC SPDs for DC defense: AC and DC SPDs are NOT interchangeable due to their distinct arc-quenching capabilities

- Compromising on quality: Selecting the most economical option rather than appropriately certified components

- Improper grounding: Positioning even the most effective SPDs with inadequate grounding installations

- Missing indicators: Choosing components without status indicators, making maintenance challenging

Conclusion

Choosing the appropriate surge protective device for your photovoltaic energy installation demands careful evaluation of multiple technical parameters and installation-specific factors. From comprehending SPD classifications and voltage specifications to assessing discharge current capability and positioning strategies, each decision affects the overall defense effectiveness of your installation. Proper SPD selection goes beyond simply purchasing the most economical component, it involves analyzing your installation’s unique vulnerability to transients, evaluating environmental conditions, and guaranteeing compliance with applicable safety standards.

Successful transient protection necessitates a comprehensive approach that combines appropriate component selection with correct installation practices and ongoing maintenance. By adhering to the guidelines presented in this resource, you can substantially reduce the risk of costly equipment damage, extend your installation’s operational lifespan, and maximize your photovoltaic energy investment’s return. Keep in mind that surge protection represents not merely an optional addition but an essential element of any reliable photovoltaic energy installation. Whether you’re working with HOA regulations or educational resources, allocate time to assess your specific requirements, consult with qualified professionals when necessary, and prioritize quality components that deliver long-term defense for your valuable photovoltaic equipment.

FAQs

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Type 1 SPDs are engineered to defend against direct lightning discharge and are positioned at main service entry locations, utilizing spark gap mechanisms to manage high-energy transients tested with 10/350 μs impulse. Type 2 SPDs deliver defense against induced transients and utility-switching occurrences, positioned at distribution panels and utilizing Metal Oxide Varistor (MOV) mechanisms tested with 8/20 μs impulse. Most residential photovoltaic installations utilize Type 2 SPDs, while structures with external lightning defense installations or those unable to maintain separation distance necessitate Type 1 SPDs. Type 1+2 integrated units are also accessible for complete defense in a single component.

To establish the correct voltage rating, determine your installation's maximum open-circuit voltage (Voc) and choose an SPD with Maximum Continuous Operating Voltage (MCOV) no less than 10% beyond this value. For illustration, a 600V DC installation needs SPDs with an MCOV of no less than 660V DC. Keep in mind that lower temperatures elevate PV array voltage, so account for your area's coldest expected temperatures. For AC side defense, choose SPDs that surpass nominal installation voltage by no less than 25%. Utilizing an SPD with inadequate MCOV will cause early failure and potential fire risks.

SPD positioning follows the "<10 Meter Rule" for DC side defense: if DC cable distance is under 10 meters, position one array of SPDs at the inverter DC input; if distance surpasses 10 meters, position two arrays, one adjacent to the PV array in combiner enclosures and another at the inverter input. For AC side defense, position principal protection at the grid interconnection point, secondary defense adjacent to the inverter AC output, and supplementary protection at sub-panels for expanded installations. Also evaluate defense for communication and monitoring installations, which are highly susceptible to transients.

Quality SPDs possess a 10-15 year anticipated service life under standard conditions, but regular inspection is essential for optimal defense. Examine visual indicators regularly for evidence of SPD activation or malfunction, particularly before storm seasons. Replace SPDs following major transient occurrences even if no external damage is apparent, as internal components may be compromised. For critical installations, choose SPDs with remote monitoring capabilities to track performance continuously. Create a regular inspection schedule that includes verifying status indicators, examining physical connections, and confirming proper grounding remains intact.

No, AC and DC SPDs are NOT interchangeable due to their distinct arc-quenching capabilities and operational characteristics. DC SPDs must manage continuous DC voltage and possess different arc extinction mechanisms compared to AC components, which benefit from the natural current zero-crossing in alternating current. Utilizing AC SPDs for DC defense creates serious safety risks and will not deliver adequate protection. Your photovoltaic installation necessitates specifically engineered DC SPDs for the array and inverter input side and separate AC SPDs for the grid interconnection and inverter output side, each appropriately rated for their respective voltage and current specifications. Understanding proper equipment specifications and load analysis requirements ensures your system remains protected throughout its operational life.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

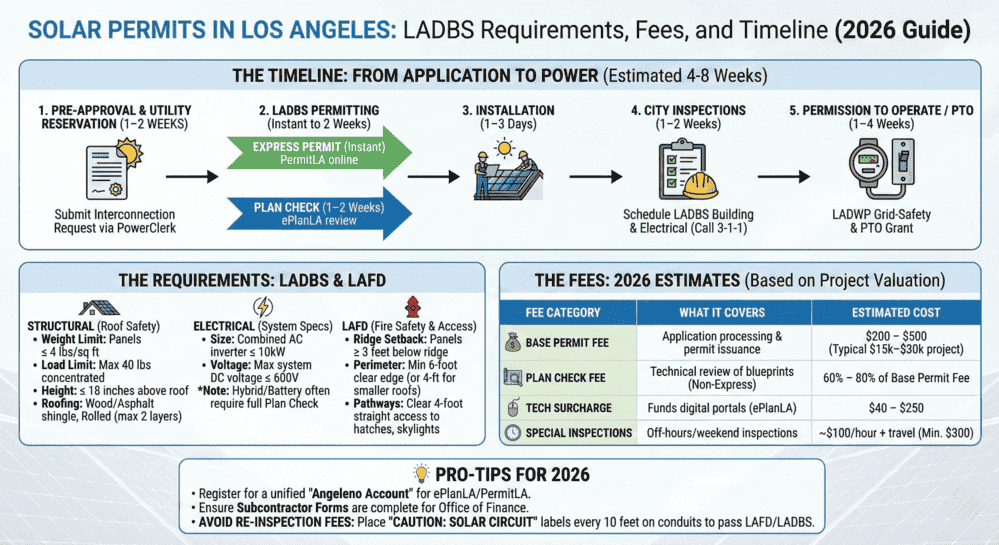

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...