Third-party solar inspections are independent quality assessments performed by certified professionals unaffiliated with manufacturers or installers. Their purpose is to verify solar system compliance with industry standards, safety regulations, and performance specifications. These inspections identify defects like microcracks, delamination, and electrical faults before they cause system failures or reduce energy output, protecting solar investments that typically operate for 25-30 years.

Independent solar inspections are necessary because they provide unbiased verification at critical project stages: pre-shipment component testing, on-site installation verification, commissioning performance validation, and ongoing maintenance audits. Without this unbiased verification, owners risk a 15-30% reduction in their investment’s return due to undetected defects, warranty voids, and underperformance. Solar systems represent substantial financial commitments, with quality issues potentially causing equipment failures, warranty disputes, or diminished energy generation over operational lifetimes.

Third-party inspections verify compliance with international standards including IEC 61215 and IEC 61730 for photovoltaic module performance and safety, ISO 9001 for manufacturing quality systems, and ISO 14001 for environmental management. Many jurisdictions now mandate inspection documentation for project financing, utility interconnection approval, and regulatory compliance, making professional quality verification essential for project approval and long-term system reliability.

Understanding Quality Control Requirements For Solar Energy Systems

Solar quality management encompasses the systematic approach to confirming that every system component meets designated performance, safety, and longevity requirements. This includes solar panels, inverters, electrical connections, and structural mounting assemblies. This process extends beyond initial installation standards to encompass the sustained efficiency and dependability of complete energy systems.

Within today’s rapidly expanding solar sector, competitive pressures can incentivize certain suppliers to compromise standards for cost reduction. Inadequate manufacturing processes, incorrect installation methods, or inferior materials result in performance deterioration, common defects in solar panels, and potential safety risks.

Comprehensive solar quality management procedures mitigate these concerns, protecting system return on investment and preserving customer trust.

Why Independent Verification Has Become Critical For Solar Projects

Third-party inspections represent independent evaluations performed by certified professionals unaffiliated with manufacturers or installers. These assessments verify quality, regulatory compliance, and safety of solar components and installations against standardized criteria.

How Unbiased Assessments Build Stakeholder Confidence

Independence constitutes the fundamental principle underlying third-party inspections. External auditors examining equipment provide stakeholders (investors, developers, or end users) with assurance that evaluation results remain unbiased.

Independent inspections function as impartial quality checkpoints, confirming products and installations satisfy international requirements including:

- IEC 61215 and IEC 61730 for photovoltaic module performance and safety

- ISO 9001 for manufacturing quality management systems

- ISO 14001 for environmental management protocols

Engaging independent specialists early and consistently throughout project development enables identification and resolution of potential problems before they escalate into expensive failures.

Frequently Discovered Issues During Professional Solar Assessments

Even established manufacturers encounter issues stemming from process variations or material inconsistencies. Independent inspectors regularly discover common defects in solar panels that compromise efficiency and safety:

1. Cell Fractures That Reduce Energy Output

Microscopic fractures, frequently invisible to casual observation, can emerge during manufacturing, transportation, or installation. These microcracks expand progressively, diminishing energy production and reducing panel longevity.

2. Layer Separation Problems

Encapsulant layer separation from glass or backsheet materials compromises moisture protection and structural integrity, ultimately causing module breakdown.

3. Electrical Connection Deficiencies

Inadequate soldering techniques or misaligned connectors create elevated resistance points, raising overheating probability and power loss.

4. Localized Overheating Zones

Inconsistent cell performance or shading conditions generate localized overheating. Hot spots reduce efficiency while increasing fire hazards when left unaddressed.

5. Voltage-Related Performance Degradation

PID develops when electrical leakage between cells and frames produces gradual efficiency reduction. This condition typically requires systematic solar panel testing for detection.

Third-party inspectors employ sophisticated diagnostic equipment such as EL imaging, IR thermography, and IV curve testing to identify these issues well before performance impacts occur.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Benefits Of Professional Verification For Solar System Reliability

Cost Reduction Through Early Problem Identification

Identifying manufacturing or installation defects during early project phases reduces warranty claims, system downtime, and expensive field replacements. Addressing problems before panel deployment proves significantly more cost-effective.

Maintaining Quality Standards Across Multiple Sites

Large-scale commercial installations spanning multiple geographic locations benefit from third-party inspections that ensure uniform quality and adherence to identical performance standards.

Maximizing Energy Generation And Financial Returns

Verifying that panels and systems meet or surpass design specifications through third-party testing enhances overall energy generation, producing superior financial outcomes.

Meeting Mandatory Inspection Documentation Requirements

Numerous jurisdictions currently require independent inspection documentation for project financing and utility interconnection. Satisfying these regulations through certified audits prevents expensive project delays.

Implementing Professional Assessments Throughout Project Development

Effective solar quality management incorporates third-party inspections throughout multiple stages of solar project development:

1. Factory Quality Verification Before Shipping

Inspectors confirm that panels, inverters, and mounting systems meet technical specifications before factory departure. Sample testing validates product integrity prior to large-volume procurement.

2. Construction Phase Installation Audits

During construction phases, inspections verify proper electrical connections, grounding procedures, mounting structure alignment, and complete system configuration. This process ensures installations satisfy design and safety criteria.

3. System Activation And Output Validation

Following installation completion, performance validation procedures such as IV curve analysis confirm systems deliver anticipated output under actual operating conditions.

4. Scheduled Performance Monitoring

Periodic inspections after system commissioning monitor degradation patterns, detect early performance decline, and optimize maintenance scheduling.

These combined stages establish a comprehensive quality audit framework, ensuring complete solar project lifecycles adhere to industry best practices.

How Rigorous Testing Protects Investment Returns

Dependable solar panel testing transcends technical requirements to function as financial protection. Panels generating below rated efficiency substantially diminish expected investment returns across operational lifetimes.

Third-party inspections maintain system reliability and minimize performance risks, particularly critical for commercial and utility-scale investors. Thoroughly documented inspection records also enhance asset valuations in secondary markets and strengthen credibility with financial institutions and insurance providers.

Selecting Expert Partners For Comprehensive Quality Verification

Selecting knowledgeable and dependable solar quality assurance partners proves essential for project success. Solar Permit Solutions specializes in ensuring comprehensive compliance with quality standards through expert permitting services, engineering support, and interconnection guidance across all 50 states.

Professional quality management expertise, combined with thorough understanding of regulatory requirements and technical specifications, ensures solar installations meet the highest international standards for safety and performance. Commitment to quality verification and system reliability builds stakeholder confidence and delivers sustained value.

Conclusion

Third-party inspections deliver measurable protection for solar investments through unbiased quality verification at every project stage. Independent assessments identify performance issues before they become expensive failures, ensure regulatory compliance for financing approval, and validate system output meets design specifications. Quality shortcuts cost significantly more than professional inspections when they result in equipment failures, warranty disputes, or reduced energy generation over 25-year operational periods.

Expert support provides comprehensive permitting, engineering stamps, and interconnection support across all 50 states, ensuring projects meet quality standards and regulatory requirements from design through commissioning. Professional guidance on inspection requirements, code compliance, and utility interconnection streamlines approval processes and protects long-term system performance. Contact Solar Permit Solutions today to secure expert support for quality-verified solar installations that deliver reliable returns.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Third-party solar inspections are independent quality assessments conducted by certified professionals unaffiliated with manufacturers or installers. They verify that solar components and installations meet industry standards, regulatory requirements, and performance specifications, providing unbiased verification that protects investment returns by identifying defects before they impact system performance or safety.

Third-party inspections should occur at multiple critical stages: pre-shipment to verify component quality, on-site during installation to confirm proper electrical connections and mounting, commissioning after installation to validate output performance, and periodically during operation to monitor degradation. This multi-stage approach ensures quality control from manufacturing through long-term operation.

Professional inspectors identify microcracks in solar cells, delamination between encapsulant layers, soldering and connection faults, hot spots from uneven cell performance, and Potential Induced Degradation (PID) from electrical leakage. Inspectors use advanced diagnostic tools like EL imaging, IR thermography, and IV curve testing to detect these issues before they significantly impact performance.

Independent inspections prevent costly problems by detecting defects early, reducing warranty claims, system downtime, and expensive field replacements. Verifying systems meet design specifications ensures optimal energy generation while documented inspection records enhance asset value and strengthen credibility with lenders and insurance providers, facilitating better financing terms.

Many jurisdictions and financial institutions mandate independent inspection documentation for project approval, with utility companies requiring verified reports before grid interconnection and banks requiring quality verification for financing. Insurance providers and regulatory agencies increasingly require documented assessments for commercial and utility-scale installations to ensure compliance with electrical codes and safety regulations.

Third-party inspections verify compliance with IEC 61215 and IEC 61730 for photovoltaic module performance and safety, ISO 9001 for manufacturing quality management systems, and ISO 14001 for environmental management protocols. These internationally recognized standards provide objective criteria for evaluating solar components and installations, ensuring systems meet rigorous performance and safety benchmarks.

Commercial and utility-scale installations typically benefit from annual or biannual inspections, while residential systems may require inspections every 2-3 years unless performance monitoring indicates issues. Systems in harsh environmental conditions or critical applications like off-grid installations warrant more frequent professional evaluation to identify degradation patterns and optimize maintenance scheduling.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

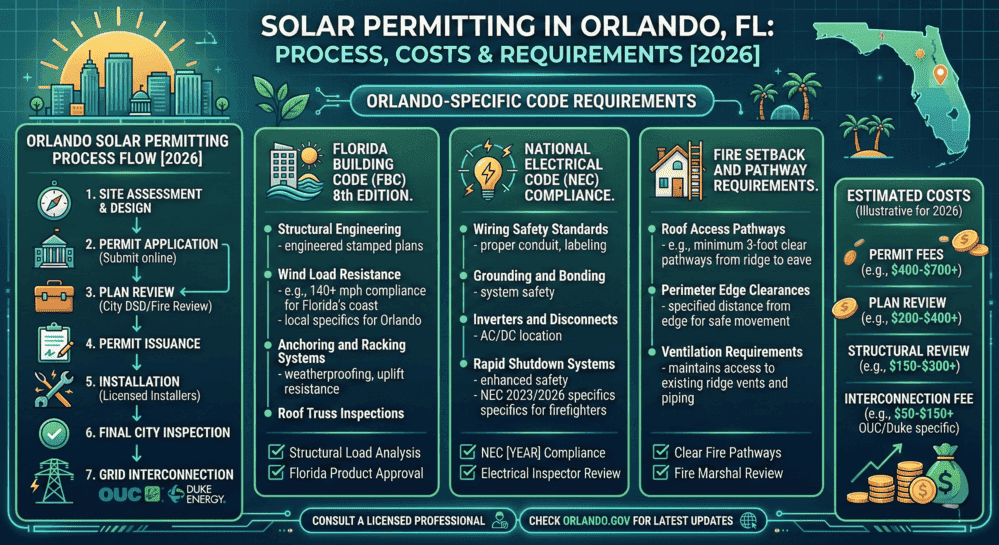

Solar Permitting in Orlando, FL: A Complete Guide for Homeowners & Installers

Solar permitting in Orlando, FL, requires a building permit and an electrical pe...

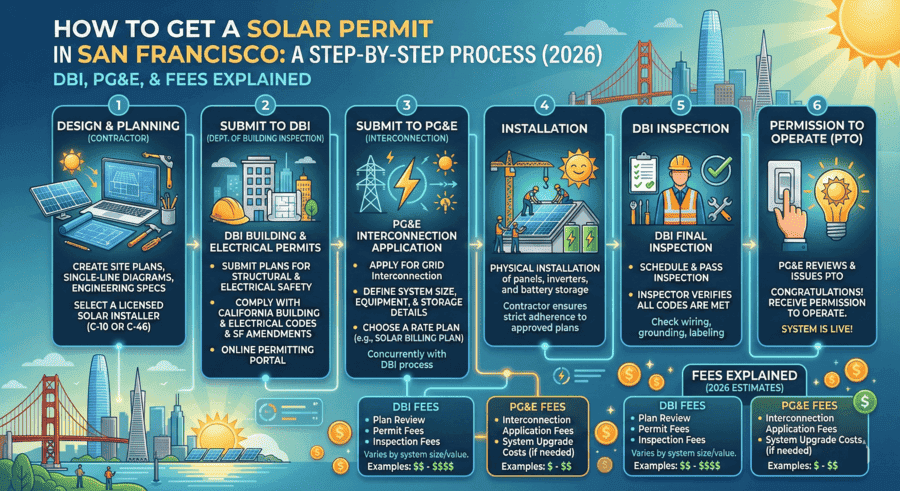

How To Get A Solar Permit In San Francisco: DBI, PG&E And Fees Explained (2026)

San Francisco solar permits require two separate approvals before your system ca...

Bifacial Solar Panel Installation And Permitting Guide

Bifacial solar panels generate 10 to 30 percent more energy than traditional mon...