Solar inspections fail primarily due to nine common violations: unpainted exterior conduits, missing smoke and carbon monoxide alarms, improper wire installation, faulty grounding connections, inadequate labeling, missing GFCI protection, electrical panel miscalculations, unsealed roof penetrations, and non-compliant emergency access configurations. These mistakes can delay system activation by weeks and add hundreds to thousands of dollars in repair costs.

City inspectors examine three critical areas during solar inspections: rough electrical work for concealed wiring, electrical bonding and grounding connections, and final inspection of the complete solar energy system including modules, panels, wire terminations, and grounding. Failed inspections prevent utility company activation and delay the financial benefits of solar energy investment.

Most homeowners lack expertise in solar installation, making code violations common in DIY projects. Systems may appear functional for weeks or months, but unpermitted solar installations often reveal costly repairs needed to pass solar PV inspection requirements. Working with licensed solar professionals who understand local permit codes significantly increases first-time inspection pass rates and ensures compliance with evolving municipal regulations.

Understanding Municipal Solar System Inspection Requirements

City inspectors examine three primary areas for solar energy systems:

- Rough electrical work for any concealed wiring

- Electrical bonding and grounding connections

- Final inspection of the complete solar energy system, including modules, panels, wire terminations, and grounding

Compliance With Building Regulations For Solar Permit Approval

City building codes and regulations exist to protect homes and commercial properties. Even minor solar permit mistakes increase electrical risks and future system issues. Failed inspections delay projects and postpone the benefits of solar energy.

Poorly installed systems not meeting current electrical codes require attention when immediate safety issues exist.

Ordinary repairs that don’t alter existing solar installation systems may not require permits. However, new solar energy system installations or plans to remove and reinstall existing systems typically require upgrades to bring components up to current code standards.

Solar installation and electrical code violations often occur unintentionally. Older homes frequently have solar energy systems that don’t meet current codes. Solar energy remains relatively new, with states and local cities regularly updating solar regulations to ensure proper and safe installation practices.

Why Certified Installers Matter For Code Compliance

Licensed solar installation professionals understand local permit and code requirements. Working with residential solar experts ensures systems function properly and pass required inspections.

For DIY projects or new solar companies, research local solar electrical codes before starting any installation project. Homeowners must obtain permits to install and activate solar energy systems with utility companies. Failing to secure proper solar permits can devalue properties and result in systems that utility companies refuse to accept.

When working with independent solar contractors or handymen, insist on proper permit acquisition. Professional solar companies always obtain correct permits, though some DIY homeowners skip this critical step.

All installations must follow approved plans. City inspectors require the following to verify correct installation:

- Safe access to inspect roof construction

- On-site personnel familiar with the installed system

- Access to building interiors to check smoke detectors and carbon monoxide alarms

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Getting Ready For Municipal System Evaluation

Proper solar PV inspection preparation focuses on demonstrating that the solar energy system matches approved building plans. Ensure all solar PV system components, including the main panel, AC/DC disconnect, and circuit breakers, remain open and available for verification upon request.

Inspectors examine three primary areas:

- Solar array mounting system and structural connections according to approved plans

- Electrical grounding and bonding of racking and modules following manufacturer’s installation instructions

- Correct solar panel module model, quantity, and location matching approved plans

Nine Critical Errors Leading To Inspection Rejection

Installing solar energy systems to match plans precisely reduces the chance of failing solar inspections. Ensure equipment is installed, listed, and labeled according to approved plans. This applies to all equipment, from solar panels and AC/DC disconnects to DC/DC converters (power optimizers), combiner boxes, inverters, load centers, and electrical service equipment.

Multiple reasons cause solar inspection failures. Here are nine common installation mistakes requiring correction before system activation.

1. Unpainted Exterior Conduit Violations

Some solar installation companies don’t paint conduits, creating problems in most cities that require exterior conduits to match surrounding surfaces. Typical EMT conduit works for exterior applications, with some cities allowing FMC conduit. All cities require clean conduit runs on roofs, under eaves, and within attics. All exposed conduits should be painted to match adjacent surfaces.

2. Missing Safety Alarm Requirements

Smoke and carbon monoxide alarms must be installed in dwelling units when building and safety permits are issued. These devices provide essential fire and life safety protection, potentially saving lives during fires or carbon monoxide poisoning events.

Smoke and carbon monoxide alarms must be installed in these locations:

- In each sleeping room

- Outside each bedroom in the immediate vicinity

- On every dwelling unit level, including basements

3. Improper Wire Installation And Sizing Errors

Complete wiring doesn’t guarantee city building inspector approval. According to state electrical codes, all work must be done neatly and in a workmanlike manner. Incomplete or messy work that’s difficult to examine may fail inspection. Disorderly electrical panel installations can lead to short circuits and electrical problems, causing property damage and serious injuries.

4. Faulty Electrical Grounding Connections

Electrical grounding represents one of the most important considerations for any electrical inspection. City building inspectors exercise extra care with solar energy systems because they function as power plants on rooftops. Proper grounding and bonding is essential, requiring solar PV system connections to grounding electrode systems to match approved plans. Metallic raceways, enclosures, and system grounding electrode conductors must be bonded at each raceway end and partition.

5. Inadequate System Labeling And Warning Signs

Improper labeling ranks among the most common inspection failure reasons. PV system markings, labels, and signs according to approved plans are essential. Labels and specific requirements ensure homeowners, future electricians, and firefighters can work safely.

Cities enforce strict signage requirements. Most cities require solar warning signage on metal or plastic with engraved or machine-printed letters, or electro-photo plating, contrasting with the plaque. Plaques must be attached to service equipment with approved adhesive, featuring minimum 3/8-inch high white lettering on red backgrounds. Conduit raceways entering buildings must be labeled and identified every 10 feet, within one foot of turns and bends, and one foot above and below roof, wall, or barrier penetrations. Proper labeling also helps prevent DC connector fires by ensuring correct system identification.

6. Missing Ground-Fault Protection Devices

This electrical issue extends beyond solar scope but remains vital for electrical safety. Ground-fault circuit interrupters (GFCIs) are electrical outlets that automatically cut power when excessive moisture or electrical current changes occur. GFCIs are required in kitchens, bathrooms, outdoors, and other areas where water is present. Even though solar PV systems don’t involve water, city inspectors may require GFCI protection additions since the last person modified the electrical panel. Inexpensive GFCI tester tools can verify outlet code compliance.

7. Electrical Panel Capacity Miscalculations

Inverter output circuit breakers must be located at the opposite bus end from utility supply at load centers and service panelboards (not required if inverter and utility supply circuit breaker sums equal or are less than panelboard bus ratings). Certain situations require downsizing the main service breaker, known as a panel derate. This prevents electrical system overheating. Breakers have maximum amperage ratings, and upsizing is not permitted.

8. Unsealed Roof Entry Points

Roof penetrations must be flashed and sealed according to approved plans. Check for plumbing vents under modules. Most solar installations attach panels to rails mounted on roofs with lag bolts. Any created holes are sealed with special sealants to prevent roof leaks and ensure weather protection. Certain roof areas should not have solar panel installations. Most cities prohibit solar panel modules from obstructing plumbing, mechanical, or roof vents.

9. Non-Compliant Emergency Access Configurations

Solar energy system regulations significantly consider fire department requirements. To enable fire departments to properly turn off solar energy systems and work on roofs, equipment location is essential. Solar energy system AC disconnects must be located on exterior walls and properly positioned for fire department accessibility.

The electrical code requires at least one pathway on the street or driveway side of each roof plane with a photovoltaic array. A minimum pathway is required from the lowest roof edge to the ridge, ensuring fire departments have safe roof access paths. Pathways must be located in areas with minimal obstructions such as vent pipes, conduits, or mechanical equipment. Proper solar array placement considers both fire access and system performance.

Complete Solar System Verification Requirements

Pre-Inspection Documentation Standards

- Approved plans, inspection record cards, and manufacturers’ installation instructions shall be available on location

- Equipment installation matches approved plans

- If solar panel installation differs from approved plans, plan or construction changes may be required

- Work shall be fully complete by inspection time

- A ladder adhering to safety requirements shall be prepared and secured for inspection

- When separate utility disconnect is required, local utility company approval notice shall be available on site

- For main panel upgrade projects, utility company service orders shall be available on site

- All required licenses, clearances, and electrical equipment permissions must be provided and maintained

- All required labels must be properly fixed in place. Understanding permit timelines helps prepare documentation efficiently.

Electrical Components And Rating Verification

- Solar energy system electrical equipment and verifiable bus ratings shall be adequate and properly sized for designed PV sources

- Electrical grounding and bonding connections shall be located and verified

- All placards and signage must be present for customer self-generating electrical equipment as required by the California Electrical Code and local AHJ compliance

- New circuit breakers shall be from the same equipment manufacturer as existing service equipment or approved on plans for use with existing electrical equipment

- When existing circuits are relocated to accommodate solar PV breakers, new panel schedules are required, and loads shall remain balanced

Rooftop Module And Mounting Standards

- All roof-mounted PV arrays and racking systems require wiring, attachment, and grounding inspection

- Inspectors must be provided safe paths to inspect and walk on roofs

- Solar mounting systems and solar modules must be installed in compliance with manufacturer’s installation instructions

- Installed mounting systems and solar panel modules should match the same models and manufacturers identified on approved plans

- Solar mounting systems must be securely attached, and roof membrane weather protection shall be maintained

- Roof solar panel arrays may not compromise or obstruct roof vents, plumbing vents, or chimneys. Commercial solar installations require additional structural considerations.

Connection Enclosures And Circuit Protection

- Wiring conductors should be the approved type and properly sized to match approved plans

- When applicable, metallic raceways containing DC source circuits over 250 volts shall be correctly bonded through concentric knockouts at boxes or enclosures

- Solar combiner boxes, DC disconnects, and fusing used in DC source wiring shall be DC rated

- Intermediate enclosures, boxes, and conduit body covers must be accessible for servicing and properly grounded

Power Conversion And Disconnect Requirements

- Signage or placards with power source operating voltage and currents shall be attached to or located adjacent to either inverters or DC disconnects

- Installed inverters, disconnects, and rapid shutoff devices shall be the same as those identified on approved plans

- Correctly sized system grounding electrode conductors shall be installed to appropriate terminals

- Metallic raceways and enclosures enclosing system grounding electrode conductors shall be bonded at each raceway end and to each enclosure

Utility Interface And Overcurrent Safeguards

- When utility companies require lockable AC disconnects, they shall be located at service equipment unless utility companies approve remote locations

- When utility disconnects are required, they shall be identified on placards as “PV System Disconnect”

- All back-fed circuit breakers and disconnects shall be labeled appropriately with correct labels or placards

Conclusion

Passing solar inspection on the first attempt requires meticulous attention to local building codes, proper installation techniques, and comprehensive documentation. The nine critical errors outlined above represent the most frequent reasons systems fail inspection, from unpainted conduits and missing safety alarms to improper grounding and non-compliant emergency access configurations. Each violation not only delays system activation but also increases project costs and postpones the financial benefits of solar energy.

Working with Solar Permit Solutions professionals who understand local permit requirements significantly increases the likelihood of inspection approval. These experts stay current with evolving regulations and ensure all components meet manufacturer specifications and municipal standards. For those pursuing DIY installations, thorough research of local electrical codes and strict adherence to approved plans becomes essential.

Proper preparation makes the difference between seamless activation and costly delays. Ensuring all system components are accessible for inspection, maintaining accurate documentation, and verifying that installations match approved plans protects the investment and expedites the path to clean, renewable energy. Whether pursuing off-grid systems or grid-tied installations, taking the time to address potential issues before the inspector arrives saves money, time, and frustration in the long run.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

When a solar installation fails inspection, the system cannot be activated or connected to the utility grid. The inspector provides a detailed list of violations that must be corrected before scheduling a re-inspection. Homeowners or installers must address all cited issues, which may involve rewiring, adding proper labels, installing missing safety equipment, or correcting structural deficiencies. Once corrections are complete, a follow-up inspection must be scheduled and passed before the utility company will authorize system activation. Design mistakes typically delay project timelines by several weeks and can add significant costs for repairs and additional inspection fees.

A typical solar inspection takes between 30 minutes to two hours, depending on system size and complexity. Smaller residential installations usually require less time, while larger commercial systems or installations with multiple inverters and complex electrical configurations may take longer. The inspector examines rough electrical work, bonding and grounding connections, roof mounting systems, and all system components. Having all required documentation readily available, ensuring clear access to all equipment, and having a knowledgeable person on-site can expedite the process and demonstrate professionalism to the inspector.

While homeowners cannot replace official municipal inspections, conducting a thorough self-inspection before the official visit is highly recommended. Review all aspects covered in the inspection checklist, including proper labeling, conduit painting, grounding connections, and equipment placement. Verify that installations match approved plans exactly, check that all required smoke and carbon monoxide alarms are installed, and ensure outlets are present where required. Using the comprehensive checklist provided by the permitting office helps identify potential issues early, allowing time for corrections before the inspector arrives. Professional solar services also offer pre-inspection reviews to catch problems beforehand.

Solar inspection requirements vary significantly between cities, counties, and states. While many jurisdictions follow the National Electrical Code and state electrical codes as baseline standards, local authorities having jurisdiction often impose additional requirements. Some cities have stricter fire department access pathway requirements, specific conduit painting standards, or unique labeling specifications. Coastal areas may have additional corrosion protection requirements, while regions with high wind or seismic activity enforce stricter mounting standards. Always research specific local codes before beginning installation and consult with local permitting experts to understand jurisdiction-specific requirements.

Solar inspection costs typically range from $200 to $500, though fees vary widely depending on location, system size, and local government fee structures. Most jurisdictions charge inspection fees as part of the overall permit cost, which can range from $500 to $2,000 or more for residential installations. Some municipalities charge flat fees, while others calculate costs based on system size or project valuation. Re-inspection fees for failed inspections typically cost $100 to $300 additional. Professional solar installation companies usually include all permit and inspection fees in their project quotes, while DIY installers must budget separately for these expenses. Contact the local building department for exact fee schedules.

Inspectors require comprehensive documentation including approved building plans, electrical diagrams, manufacturer specifications for all equipment, installation instructions, inspection record cards, and proof of proper permits. For systems requiring utility disconnect, utility company approval notices must be available. Projects involving panel upgrades need utility service orders on-site. All equipment certifications, warranties, and compliance documentation should be organized and accessible. Proper ladder access must be prepared for roof inspections. Having a complete documentation package demonstrates professionalism and preparation, making the inspection process smoother and increasing the likelihood of first-time approval.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

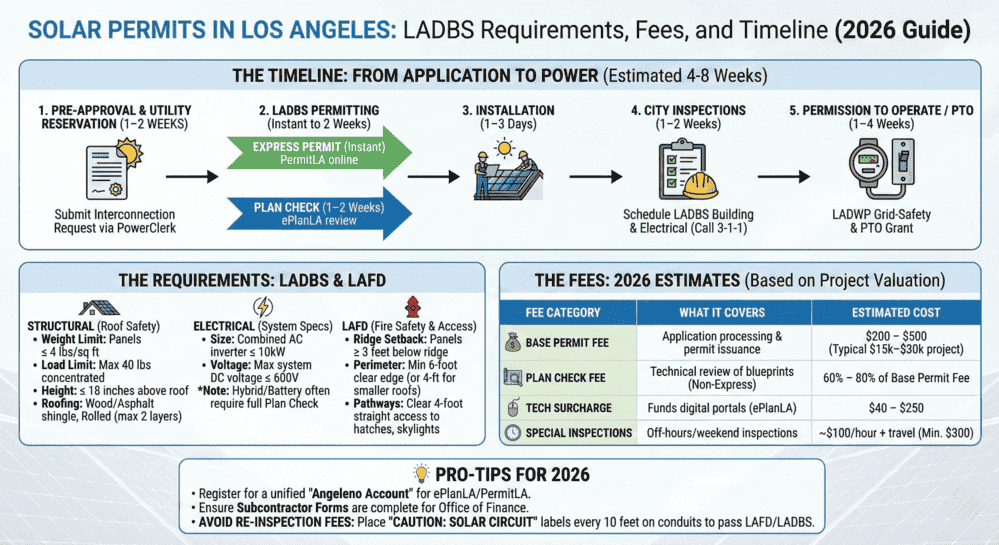

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...