Solar panels work efficiently in winter and actually perform better in cold temperatures, but snow and ice pose serious risks that require specific protection strategies. While temperatures above 77°F decrease solar panel voltage, cold weather enhances operational efficiency.

The challenge lies not in the cold itself but in managing the physical threats of snow accumulation, ice buildup, and frost heave that can damage or destroy unprotected systems.

Winter weather threatens solar installations across most of the United States. Heavy snow accumulation (averaging over 30 inches in January) affects 18 states, primarily in mountainous regions west of the Rockies, Great Lakes coasts, and Appalachian areas.

Ice storms present a separate risk, predominantly impacting the Great Plains and parts of the Southern United States. Each threat requires distinct protective measures since snow and ice adhere to solar systems through different mechanisms.

Protecting solar panels from winter damage involves three critical phases: design and equipment selection, system configuration, and ongoing maintenance protocols.

Key protective measures include selecting modules rated for at least 5000 Pa load capacity in heavy snow regions, implementing tilt angles of 30 to 35 degrees for optimal snow shedding, elevating systems at least two feet above maximum snow depth, and designing foundations that extend below frost depth to prevent ground movement damage.

This comprehensive guide covers winter resilience strategies for solar system designers, installers, owners, and operators throughout the complete system lifecycle, from initial design decisions through post-storm recovery procedures.

Whether planning a new installation in a cold climate or protecting an existing system, Solar Permit Solutions provides proven approaches that minimize winter damage, reduce repair costs, and maintain reliable year-round energy production. For detailed cold climate design considerations, comprehensive technical manuals offer additional engineering guidance.

Understanding Winter Weather Threats To Solar Systems

PV modules demonstrate enhanced operational efficiency in colder temperatures, as heat above 77°F results in voltage decreases. Despite this advantage, winter weather threats like ice and snow present substantial design and operational challenges for PV systems in these regions and can restrict power production capabilities.

Extended exposure to severe winter weather conditions can seriously disable or damage a PV system, resulting in significant repair expenses and production losses when the system lacks proper design to withstand these environmental stresses.

Most snow naturally melts quickly off PV systems or gets removed by wind action. Heavy snow accumulation or extreme winter weather events, however, create greater risks to the resilience and operational lifespan of PV installations. During intense snowstorms, accumulated snow weight on a PV module may cause warping or complete breakage.

Ice formation on a PV system surface can both increase and significantly redistribute system weight, potentially over-straining specific components including module frames and underlying support structures.

The majority of United States territory experiences snow conditions or varying degrees of winter weather hazards that could damage or disrupt PV system operation. Historical data from the past three decades demonstrates that although snow occurs throughout the nation, areas receiving the deepest January snowfalls (averaging more than 30 inches) during this timeframe have typically been located in sections of 18 states, including:

- Mountainous or high-elevation areas in all states west of or containing the Rocky Mountains (excluding Arizona), including:

- Blue Mountains

- Cascade Ranges

- Colorado Plateau

- Columbia Plateau

- Independence Mountains

- Markagunt Plateau

- Great Lakes-facing coasts of Michigan and Wisconsin

- Appalachian areas in West Virginia

The geographic distribution of ice storm risk differs significantly from snowfall depth distribution patterns. Ice storm hazard risk varies considerably across different counties throughout the United States.

Regions most vulnerable to ice storms include sections of the Great Plains region, encompassing Kansas, Nebraska, North Dakota, Oklahoma, and South Dakota; portions of the Southern United States, including sections of Arkansas, Kentucky, Missouri, and Texas; and other isolated counties.

Ice storm risk pertains primarily to areas with relatively flatter topography, compared to heavy snowfall accumulation risk, which relates mainly to high-elevation areas and high-latitude locations.

This distinction proves crucial as snow and ice adhere to PV systems through different mechanisms and require specific mitigation solutions. Anti-snow PV coating applications need to address water already in frozen form, whereas anti-ice PV coating applications must first prevent precipitation from freezing on surfaces and then facilitate rapid conveyance off the system.

Strategic Approaches For Winter-Ready Solar Installations

This section outlines measures to prevent damage to PV systems and increase production in areas vulnerable to extreme winter weather. These include considerations during the design, procurement, and installation phases of projects as well as during the performance period (including after a winter weather hazard has occurred).

Planning And Equipment Selection For Cold Climates

Designing a PV system to survive the conditions it will encounter over its expected lifetime (typically 25 to 30 years) remains crucial. System design encompasses module selection, racking parameters, module attachments to racking or roofing, system layout optimization, and foundation design.

Choosing The Right Solar Modules For Snow Loads

Understanding Load Ratings And Testing Standards

Modules undergo testing for load-bearing capacity and typically are certified according to test standard IEC 61215. Load ratings are specified in Pascals (Pa). A typical module rating measures 2400 Pa.

For locations at risk of heavy snow accumulation, select modules certified to withstand at least 5000 Pa. Refer to module installation manuals to identify static (snow) test load ratings for the specific mounting configuration planned for use. Adding mounting points can also increase the load rating. Smaller modules can typically withstand higher loads.

PV modules normally are installed in a tilted position, causing snow to slide down panels and accumulate unevenly at the bottom edge of the panel at the frame, resulting in greater stress on the lower portion of the module.

IEC standard 62938 for framed modules provides a method to determine the load-bearing capability of modules subjected to non-uniform snow loads.

Snow loads for specific sites typically are calculated using ASCE 7 standards that result in a ground snow load in pounds per square foot (psi). These ground snow loads are used in formulas which factor in site specifics to yield a roof snow load for rooftop systems.

Professional load calculations ensure compliance with local requirements.

When calculating loads, avoid assuming uniform loading across a PV system; factor in that the lower side of modules typically experiences more loading than the higher side, causing increased stresses on the module.

Frame Styles: Weighing Snow Shedding Against Structural Strength

Modules typically feature metal frames around the perimeter of the PV module, though some modules are frameless.

Frameless modules can shed accumulated snow more quickly since frames can prevent snow at the lower tip of panels from sliding off after heavy snowfall. Frameless modules, however, may possess lower snow and wind load ratings than framed modules. Load rating should serve as the priority consideration over snow-shedding ability, following structural design requirements and building code standards.

Advanced Cell Technology For Heavy Load Protection

Under heavy loads, invisible cracks can form in solar cells. Modules with multi-busbar solar cells demonstrate a lower risk of propagating these cracks. The solar cell width between the busbars on multi-busbar PV panels has a smaller surface area than traditional busbar technology, limiting crack growth space. When cell cracks grow, they can lead to decreased production and possibly fire safety risks.

Emerging Surface Treatments For Ice And Snow Management

Coatings and treatments for PV systems that would facilitate automatic removal of snow and ice from system surfaces are currently under development and lack maturity at the time of writing.

Configuration And Layout Strategies For Winter Performance

Optimizing Panel Angles For Snow Removal

Higher tilt angles allow snow to shed from systems more quickly and reduce damage risk. The steeper the angle, the better the snow shed (up to 60 degrees).

Significant gains occur around 30 to 35-degree tilt angles, which is significantly steeper than a typical roof. Furthermore, the steeper the module tilt angle, the less snow weight transfers to the module.

Selecting a higher tilt angle, however, will result in higher wind loads on modules, and thus higher costs, so system designers should find the ideal compromise between these drivers as well as solar production.

Smart Tracking Systems With Winter Mode Features

PV tracker systems can adjust their angle relative to the ground. When installing a tracker system in a heavy snow region, select one with “snow stow” mode capability. This feature leverages the same steep tilt angle principle discussed above, automatically tilting panels to shed snow during heavy weather events. Snow stow can be engaged manually or automatically.

This functionality may not be available during heavy snow events, especially if communication with the system is lost. Ensure system designers design for the worst-case scenario where the tracker cannot stow or shed any snow.

Overall, tracker systems typically mount modules closer to the center of the module, leaving the ends less supported. When installing a tracker system, ensure that module load calculations are performed using the actual attachment points on the module, rather than simply using load ratings given on a specifications sheet. Commercial solar installations with tracker systems require especially careful engineering analysis.

Elevation Requirements For Snow Accumulation Zones

Snow that has fallen or been shed from a PV system may accumulate on the ground. In areas prone to heavy snowfall, elevate the bottom edge of systems higher above ground to accommodate at least two feet above maximum normal snow depth. This will have cost implications and increase the wind load, so weighing these factors and risks remains important.

Reinforced Mounting Points And Structural Support

A greater number of attachment points on a module could increase its ability to withstand heavy snow loads. Modules typically use four attachment points, though more are possible.

One high-elevation location experienced a harsh winter that left modules crushed. The damaged modules (that were attached at four points) and racking were replaced with new modules that attached to the racking at eight attachment points. Additional module supports were also added underneath the modules. These retrofits survived the following winter without damage.

Foundation Design To Prevent Ground Movement

As ground in cold climates freezes and thaws, foundations on structures can work their way up out of the ground. This can cause damage to or even toppling of a ground-mounted PV system.

Consideration of frost heave is not always required on projects and is not mandated in ASCE 7 building codes that are typically used, so require design engineers to account for frost.

Ensure frost depth is considered in the design, type, and depth of foundations; the pile depth should extend significantly below the frost depth. Guidance for calculating frost heave forces is provided in technical engineering literature.

Use a design engineering firm with experience and success installing PV in cold weather climates and require that they perform frost heave calculations in the system design. Soils vary from site to site and can vary across a site, so design foundations for the specific conditions present. This may require a pile pull test.

Landscape Format Benefits For Faster Snow Clearing

Orienting PV modules in landscape format can help accelerate shedding of snow or ice covering a PV panel. This orientation will also increase production as snow typically melts and first exposes the tops of modules.

The PV module produces power from three discrete sections: when viewed in landscape this would be the top third, middle third, and lower third. When each of these thirds of the module are clear of snow, they can produce power.

Wind-Assisted Snow Prevention Techniques

In areas where wind generally blows from a single direction, PV system operators can take advantage of the venturi effect, where a current of fast-moving wind crests over the top of a sloping obstacle and then speeds away from the object.

For PV systems, installing a curved “venturi” deflector at and pointing the top of the PV panel against the direction of wind can help ensure that snowdrifts or water-bearing winds do not make contact with panel surfaces, reducing the risk of snow or ice accumulation.

Vertical Installation Advantages In High-Snow Regions

Taking the tilt angle principle to its extreme, vertical PV installations are fixed at a 90-degree angle relative to the horizon. This configuration prevents snow and ice accumulation more effectively than any other orientation, as precipitation simply cannot settle on the vertical surface.

At high latitudes, their extreme orientation also means that they can capture the low angle of the winter sun more effectively.

Ground-mounted vertical PV can be placed in areas that would otherwise be infeasible for ground-mounted horizontal PV since vertical PV uses space more efficiently and may be placed among existing land uses, such as parking or farmland. Vertical systems work particularly well for off-grid installations in remote locations.

Wind loading, though, will be higher on vertically mounted PV systems, which needs evaluation against the benefits of a vertical PV system.

Additional Design Elements For Extreme Weather

- Avoid systems with substantial cantilevers.

- Thicker and deeper frames around modules could increase the load capacity of the module and help prevent glass breakage.

- Thicker gauge racking will provide a more robust structure more likely to withstand heavy snow and ice loads.

- More spacing between modules or between “tables” of modules can possibly give snow more space to shed, aid melting, and break up large masses of snow accumulation.

- Consider combined snow and wind loads in the design as these hazards often occur together.

Accounting For Ice Buildup In Structural Calculations

Categorize solar racking as “ice-sensitive structures” as defined by ASCE 7. This will require design to account for ice buildup on the racking structure. For roof-mounted systems, position modules up to the top of the roof and include a barrier to prevent ice dam buildup.

Protecting Electrical Components From Freezing Conditions

While keeping water out of electrical components always remains important, water ingress can pose additional risk in cold weather climates. Water that enters an electrical enclosure can freeze and expand, damaging system components. Enclosures should maintain NEMA 4 or higher rating. Proper grounding and bonding procedures further protect against electrical hazards.

As snow melts and freezes, it can form icicles on a PV system. Icicles can add weight and pull on light system components such as wiring, so use wire management solutions that will hold under added weight. Do not use plastic wire ties and ensure wire connections are under modules or otherwise protected from where icicles will form.

Ongoing Management And Storm Response Protocols

Developing A Winter Weather Preparedness Plan

Development of a hazard mitigation plan that accounts for winter weather hazards can help reduce the overall impacts of ice storms, heavy snow, and frost upon PV systems. Having a post-hazard recovery plan in place when a winter weather hazard occurs will help ensure that the PV system can quickly resume power generation with minimal cost.

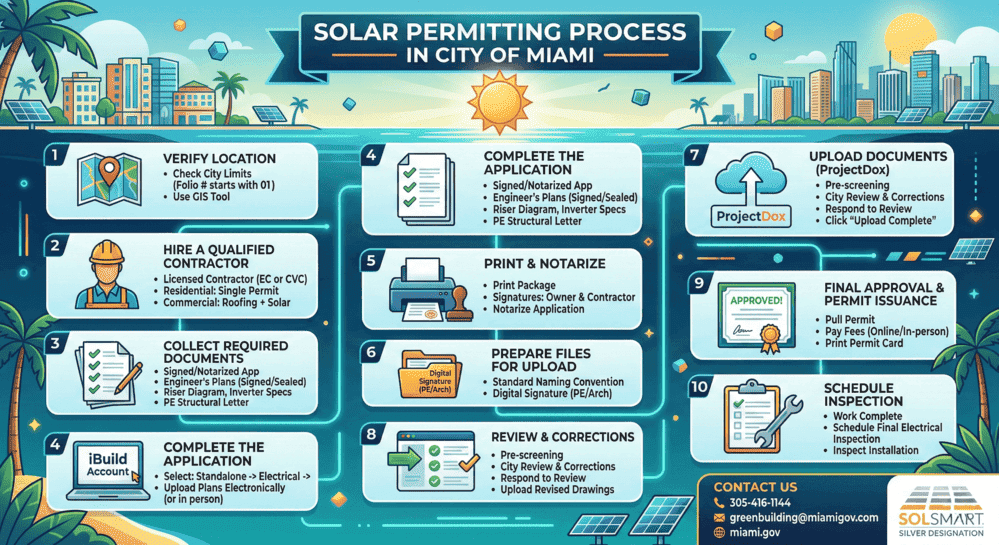

Verify AHJ requirements and permitting processes before installation to ensure compliance with local winter weather design standards. The plan should:

- Identify roles and responsibilities for various parties involved in the PV system’s operations, their expertise and capacity for addressing the hazard, and applicable funding sources to implement the plan.

- Identify actions for repairing the damaged PV system, the responsible actors for repairing the PV system, and funding sources they can use to absorb the costs of repair.

Installing Visual Markers To Protect Buried Systems

In situations where many feet of snow bury a PV system, avoid the potential for accidental damage (such as stepping on the glass surface of the PV panel or damaging it with snow removal equipment) by installing poles several feet in height along the corners and perimeter of the system and signage to alert crews of the presence of a PV system.

These poles can help snow removal workers identify the system’s location and avoid damaging the system. This is especially important in systems adjacent to parking lots or roads where snowplows may inadvertently damage a PV system.

Safe Snow Removal Practices And Cautions

Removal of accumulated snow or ice is not recommended. If attempted, it should be performed with extreme caution and care.

Shovels can cause damage and attempting to remove snow off panels can do more harm than good. Stepping or standing on panels will cause damage, and crews are often not aware of these risks or may unintentionally put weight on panels.

If snow accumulation is excessive and a site chooses to remove snow, use softer tools like brooms, such as brooms and brushes to remove snow above the panels.

Preparation Steps Before Severe Winter Storms

In the event of an impending severe storm, system survival should take precedence over power production. Power production is likely to be minimal during a storm, regardless, and damage could lead to system downtime for extended periods that would be far more costly.

- Only if there is substantial existing snow accumulation and a high risk of catastrophic structural overload from the incoming storm should removal be considered. If removal is absolutely necessary and can be done safely from the ground without stepping on panels, gently brush at the snow with a soft broom. Do not apply pressure or attempt to clear it completely.

- Remove snow from the ground or roof around the system to allow snow shedding.

- Ensure communication with system is intact, especially for tracker systems.

- Power down system and inspect after the storm before powering back on.

- If the system connects to an energy storage system like a battery, fully charge the battery.

- If accessible, ensure gutters and drainage systems are clean.

System Inspection And Recovery After Winter Events

In locations prone to extreme winter weather, a trained professional should inspect the system after each winter season or after an extreme weather event. Contact professional services for comprehensive inspections. Proper insurance and liability coverage protects against financial losses from winter damage.

Visually check for broken glass, detached metal module frames, and warped modules. Assess the environmental impacts when planning system repairs or modifications.

If the system is easily accessible, ensure modules are still securely attached to the racking or roof. Visually check that electrical cables are still routed securely and attached. Check that energy production of the system is as expected.

If damage is detected, the system should be disconnected and corrective repairs should be completed, including replacing damaged modules.

Conclusion

Protecting solar PV systems from winter weather challenges requires comprehensive planning, strategic design choices, and proactive maintenance protocols. While cold temperatures actually enhance solar panel efficiency, the physical threats posed by snow accumulation, ice formation, and frost heave demand careful attention throughout the system’s lifecycle.

Successful winter resilience starts with proper system design. Selecting modules with adequate load ratings (at least 5000 Pa for heavy snow regions), implementing optimal tilt angles between 30 to 35 degrees, ensuring robust foundation designs that account for frost depth, and using advanced features like multi-busbar solar cells provide essential protection against winter stresses.

Equally important are operational strategies that prioritize system survival during severe weather events, including proper perimeter marking, hazard mitigation planning, and knowing when manual snow removal causes more harm than good. Research validates that these comprehensive protective approaches significantly reduce winter-related system failures.

The investment in winter-hardened solar systems pays dividends through reduced repair costs, minimized production losses, and extended system lifespans. By implementing these strategies, solar system owners and operators in cold climates can harness reliable renewable energy year-round, regardless of what winter weather brings.

Professional solar design services ensure proper implementation, and comprehensive permitting guidelines facilitate smooth project approval.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

FAQs

Can ice damage my solar system even if snow doesn’t accumulate?

Yes, ice presents distinct challenges separate from snow accumulation. Ice formation on solar panels adds weight and redistributes it unevenly across the system, potentially over-straining module frames and support structures. Ice buildup on racking structures can stress components beyond design limits, which is why solar racking should be categorized as “ice-sensitive structures” according to ASCE 7 standards. Additionally, water that enters electrical enclosures can freeze and expand, damaging internal components. This makes proper enclosure ratings (NEMA 4 or higher) and protection against water ingress critical in cold climates.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Snow removal from solar panels is generally not recommended. Most snow naturally melts or slides off within a few days on properly tilted systems. Manual removal can scratch panels or cause damage from pressure on frames. If snow accumulation is extreme and threatens structural damage, use only soft tools like brooms or brushes, sweeping gently without applying direct pressure.

Tilt angles between 30 and 35 degrees offer strong snow shedding performance while balancing wind loads and installation costs. Steeper angles up to 60 degrees shed snow even more effectively but may increase structural costs and reduce overall annual energy production. The optimal tilt depends on local snow patterns, wind conditions, and cost factors, and should be evaluated by a solar engineer experienced in cold climates.

Solar panel load ratings are listed in Pascals (Pa) in the module manual or spec sheet. Standard modules typically have a 2400 Pa rating, which may be inadequate for heavy-snow regions. Areas with severe winter weather should use modules rated at least 5000 Pa. Always verify that the load rating aligns with your mounting configuration, as attachment point locations impact real-world load capacity.

Yes. Ice can add significant and uneven weight to solar panels, stressing frames and racking. Ice accumulation on mounting structures can exceed design limits, and water that enters electrical enclosures can freeze and expand, causing internal damage. Systems in cold climates should use properly rated enclosures (NEMA 4 or higher) and ensure strong protection against water ingress.

Frost heave occurs when ground repeatedly freezes and thaws, slowly pushing foundations upward. This movement can damage or destabilize ground-mounted solar systems. Because frost heave is not fully addressed in ASCE 7 building codes, system owners must ensure engineers account for frost in design plans. Foundations must extend below local frost depths, which vary by location and soil type. Work with engineers experienced in frost heave mitigation for similar climates.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

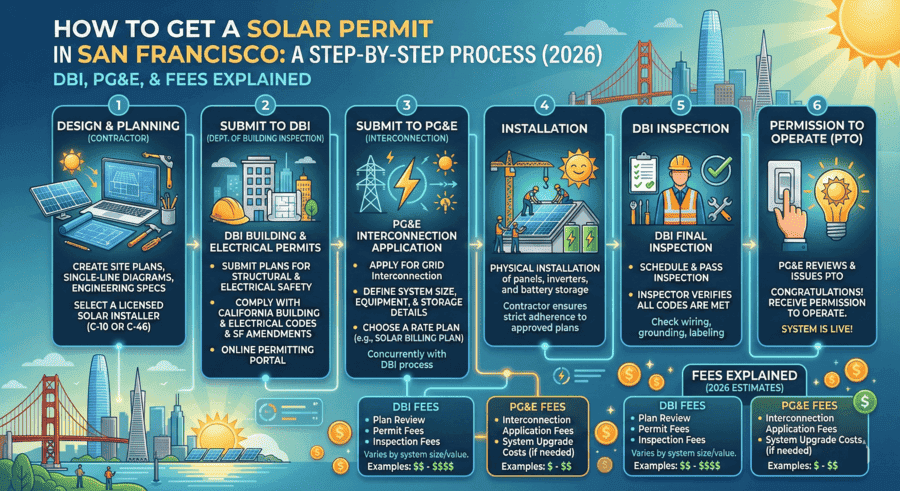

How To Get A Solar Permit In San Francisco: DBI, PG&E And Fees Explained (2026)

San Francisco solar permits require two separate approvals before your system ca...

Bifacial Solar Panel Installation And Permitting Guide

Bifacial solar panels generate 10 to 30 percent more energy than traditional mon...

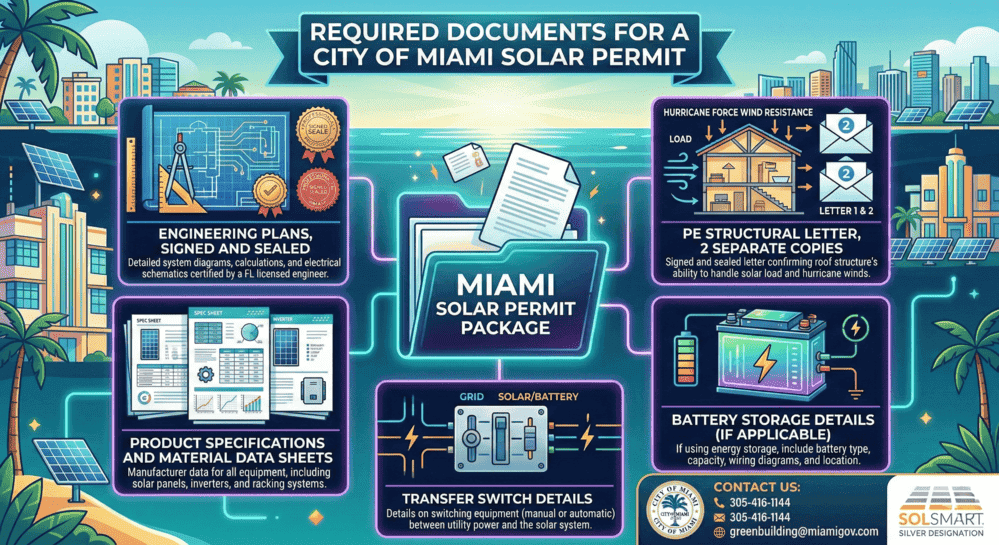

Solar Permit in Miami, FL: City of Miami vs. Miami-Dade County (2026)

Getting a solar permit in Miami requires two separate processes depending on jur...