Incomplete or non-compliant documentation is the leading cause of solar permit rejections, costing installers weeks of delays and thousands in rework. Solar energy diagrams are technical drawings that illustrate how solar power systems are designed, installed, and connected to electrical grids. These blueprints show the flow of electricity from solar panels through inverters, disconnect switches, and into the main service panel or utility grid. A complete set typically includes single-line diagrams, wiring schematics, site plans, and array layouts.

What are solar diagrams used for? They serve three primary purposes: ensuring NEC code compliance, securing permit approvals from authorities having jurisdiction (AHJs), and providing installation guidance for field crews. Installers use these technical drawings to prevent wiring errors. Engineers rely on them to verify system safety and calculate electrical loads.

Types of solar diagrams required for permitting: Most projects need a single-line diagram (SLD) showing electrical connections, a site plan indicating array placement and property boundaries, a roof layout for panel positioning, and a wiring diagram detailing conductor specifications. Grid-tied systems require additional interconnection diagrams showing utility meter connections, while battery backup systems need energy storage documentation per NEC Article 706.

Key components shown in solar panel diagrams: These plans use standardized electrical symbols to represent photovoltaic panels, inverters (string, micro, or central), combiner boxes, disconnect switches, grounding electrodes, rapid shutdown devices, utility meters, and main service panels. Each component is labeled with voltage ratings, current capacity, wire gauges, and conduit sizes to meet NEC Article 690 requirements.

Solar Permit Solutions provides permit-ready documentation and engineering reviews that help reduce delays, minimize costly changes, and accelerate approvals. Professional diagrams are designed to meet AHJ standards nationwide.

Why Solar Diagrams Are Critical for Installation Success

Solar diagrams act as blueprints showing how panels, inverters, and wiring connect for safe, efficient system design.

These diagrams are vital for NEC compliance, inspections, and permitting, helping projects move faster with fewer design errors.

Accurate system diagrams improve performance and help homeowners and installers verify every part of the solar layout before installation.

Essential Solar Diagram Types for Every Project Stage

Every type serves as a specialized blueprint, guiding the planning, permitting, and installation of a system. A professionally prepared set is critical for maintaining NEC code compliance, securing timely AHJ approval, and ensuring long-term system performance.

Professional reviews of thousands of permit plans have grouped these drawings into categories based on their function in a solar project.

1. Single-Line Diagram: The Core Electrical Schematic

The single-line diagram (SLD) stands as the most critical schematic in any permit plan set. It provides a simplified, high-level view of the entire electrical system, detailing the flow of power from the modules to the point of utility interconnection.

The SLD uses standardized symbols and a single line to represent each current path, making the design clean and easy for AHJs and utility reviewers to interpret.

Function: Illustrates how major electrical components such as the array, combiner boxes, inverters, disconnect switches, and the main service panel are connected.

Synonyms: This is often referred to as an electrical solar diagram or an electrical one-line diagram.

Compliance & Permitting: The SLD is required for nearly all interconnection applications. It serves as the primary document used to confirm compliance with fundamental NEC requirements, especially for safe interconnection in on-grid solar system designs.

2. Wiring Diagrams: Installation-Level Detail for Field Crews

While the SLD shows the what and how of the electrical flow, the wiring diagram shows the granular how-to-install details. This highly detailed schematic captures every physical electrical connection.

Function: Provides granular detail for electricians, including wire sizes and types, specific conductor colors, conduit paths, and precise terminal locations.

Installation Support: It complements the SLD by giving field teams the necessary information to install the system correctly and safely. This minimizes installation errors.

Compliance: This drawing is crucial during the construction phase. It supports compliance with NEC Article 690 (PV Systems) and NEC Article 705 (Interconnected Sources), helping to avoid violations that can delay Permission to Operate (PTO).

3. Array Placement and Site Plans: Positioning for Optimal Performance

This category focuses on the physical placement of the system, ensuring structural integrity, fire safety, and compliance with property boundaries. It consolidates information typically found across panel layout, roof, and site plan drawings.

Array Layout: This portion visually depicts the precise placement of panels on the mounting surface (roof or ground). It includes panel orientation (azimuth), tilt angles, and row spacing. Proper placement is essential to avoid obstructions (chimneys, vents) that cause shading.

Roof Compliance: For roof-mounted systems, the layout must clearly show compliance with fire code setbacks (per NEC 690.12 and IFC 1204). It must also verify that the system is engineered to the roof’s structural load limits.

Site Plan: This provides an overview of the entire property. It shows the array’s location relative to lot boundaries, the utility service entrance, and any required trenching for conduit. This drawing is key to verifying zoning compliance.

4. Safety and Performance Documentation: Protecting System Integrity

These specialized drawings forecast energy generation during planning stages and ensure crucial safety protocols are implemented during installation.

Shading Analysis Diagram: Models the sun’s path throughout the year using tools like PVsyst or Helioscope. It simulates how trees or nearby buildings will cast shadows, allowing designers to reposition panels for maximum solar exposure and predict seasonal irradiance losses.

Solar Power Monitoring Diagram: Details the data flow pathway, outlining connections between inverters, data loggers, sensors, and communication gateways (Wi-Fi/cellular). This allows installers and system owners to track real-time performance, inverter status, and energy metrics (production and net metering data) for proactive maintenance.

Grounding and Bonding Diagram: Shows how all conductive components are safely interconnected and grounded. Following NEC Article 250 and NEC 690.43, this ensures protection from electric shock, fire hazards, and lightning strikes. Proper grounding and bonding techniques are essential for system safety.

Monitoring Diagrams: Real-Time System Performance Tracking

This type shows how energy data moves from the solar array to the monitoring platform. It outlines the connections between modules, inverters, data loggers, sensors, and communication tools such as Wi-Fi or cellular gateways.

Real-time monitoring allows installers and system owners to track key performance metrics. These include energy production, voltage, current, and inverter status. Identifying issues like inverter faults or drops in solar output helps ensure proactive maintenance and reliable system performance. In on-grid systems, monitoring components also track energy exported to or imported from the utility grid. This information can impact net metering credits and time-of-use rate savings.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Shading Analysis: Maximizing Panel Efficiency Through Strategic Placement

This specialized plan is used during the site assessment or design stage. It models the sun’s path throughout the year and simulates how objects like trees, chimneys, or nearby buildings will cast shadows on the array.

Created using advanced design software tools, it includes sun paths, horizon lines, and monthly irradiance losses. Installers use this data to position panels for maximum solar exposure while avoiding significant shading that can reduce system performance. It is especially critical in residential rooftop systems where space is limited and partial shading can impact multiple panels in a string.

Rooftop Layout Plans: Compliance-Driven Installation Mapping

The solar roof layout provides a top-down view of where each panel will be installed on the rooftop. This plan accounts for array dimensions, rafter/truss spacing, roof pitch, fire code setbacks, and obstructions like vents and skylights.

In roof-mounted systems, this layout ensures structural load distribution is acceptable. It also confirms that panel placement complies with fire and building codes such as IFC Section 1204 and NEC 690.12. These plans are commonly submitted for permit approvals and utility interconnection.

One-Line Diagrams: Component-Level System Architecture

An electrical one-line diagram is a refined version of the single-line diagram. It offers a more detailed breakdown of each component in the current path. This schematic illustrates how solar panels connect to combiner boxes, inverters, rapid shutdown devices, disconnects, and the main service panel using standardized electrical symbols.

This type is especially important for commercial or grid-tied residential systems. Utility coordination, system size, and code compliance require clarity and precision. Installers use these plans to pass inspection and avoid costly revisions.

Grounding and Bonding Plans: Critical Safety Infrastructure

This critical safety document illustrates how all conductive parts of a solar system are safely interconnected and grounded. It includes the location of grounding electrodes, equipment grounding conductors (EGCs), and bonding jumpers that connect racking, inverters, combiner boxes, and service panels.

Following NEC Article 250 and NEC 690.43, proper grounding and bonding are essential. They prevent electric shock hazards, reduce the risk of fire, and protect the system from lightning strikes or power surges. A well-documented grounding plan is especially important in regions with high lightning activity or for larger residential and commercial systems. It is often reviewed during permitting and inspection to confirm compliance with local and national electrical codes.

Irradiance Profiles: Energy Production Forecasting and ROI Analysis

An irradiance profile is a planning-stage document that evaluates how much solar radiation a specific location receives on a daily, monthly, and annual basis. Using tools like LiDAR, solar maps, and meteorological data, this plan predicts expected energy generation based on panel tilt, azimuth, and potential shading.

Irradiance profiles are especially useful in the planning stages of a project. They help estimate the production capacity of solar panels and potential return on investment. Installers and designers use these profiles to optimize system design for maximum efficiency and ensure that the layout considers seasonal changes in sunlight availability. Additionally, these profiles support financial forecasts. They are often required by utilities and permitting authorities to verify expected energy output.

Bill of Materials: Comprehensive Component Documentation

Although not a visual diagram in the traditional sense, a BOM list details every component in a solar installation. It includes solar panel models, inverters, mounting hardware, wire types, combiners, and rapid shutdown devices, with part numbers and specifications.

This document supports procurement and reduces errors in installation. It ensures compliance with permit submittals. A BOM is often paired with layout plans to match components with their physical placement.

Block Diagrams: Simplified Energy Flow Visualization

A PV system block diagram is a simplified, educational version that shows how all major components interact. It includes solar panels, charge controllers (if off-grid or hybrid), inverters, batteries (optional), and the grid.

While it doesn’t replace an electrical one-line schematic, this block-level overview helps stakeholders visualize energy flow. This includes DC-to-AC conversion and grid tie-in. It’s especially useful during client presentations, training, or early-stage design discussions.

Advanced Documentation for Complex Installations

In more advanced solar installations, especially those subject to strict permitting requirements, additional types of documentation are often needed beyond the standard plan set. These specialized drawings provide greater clarity for utility coordination, safety, and code compliance.

String Wiring Plans

This type shows how solar modules are grouped into strings and wired to string inverters or combiner boxes. It helps ensure that the system operates within the correct voltage and current ranges. String configuration documentation is especially important in on-grid systems, where string-level performance and inverter compatibility must be clearly documented.

Conduit Routing Plans

The conduit and wiring layout maps the physical routing of conductors and conduit between major components. These include the solar array, inverters, disconnects, and service panels. This plan is useful during installation. It may be required by some AHJs to verify that wiring paths comply with NEC spacing, protection, and labeling requirements.

Rapid Shutdown Documentation

Under NEC 690.12, solar systems must be capable of quickly reducing voltage at the array level for firefighter safety. A rapid shutdown plan shows the location and wiring of module-level shutdown devices, such as MLPEs or rapid shutdown inverters. It also shows how they connect to disconnect switches and the service panel. This documentation is critical for permitting. It must demonstrate full compliance with rapid shutdown requirements in on-grid system designs.

Energy Storage System Plans

A battery storage plan is a specialized document used in hybrid and backup solar systems. It shows how solar panels, inverters, and batteries interconnect. This often includes components like battery management systems (BMS), critical load panels, and transfer switches. This type of documentation is vital for ensuring both code compliance and safe energy storage operation, especially in on-grid systems that include backup power.

Under the 2023 and 2024 updates to NEC Article 706, battery energy storage systems (BESS) must meet specific requirements. These include disconnects, labeling, and fire protection. Accurate documentation helps AHJs verify compliance and installers avoid delays or safety issues.

Property Layout Documentation

A site plan shows the spatial layout of the solar array in relation to the property’s rooflines, lot boundaries, and electrical service entrance. This plan is a standard part of most permit plan sets. It is used to ensure fire access pathways (per NEC 690.12 and IFC 1204), setback rules, and zoning compliance are met.

For rooftop installations, the plan must show array orientation, setbacks from ridgelines, and any obstructions like skylights or vents. For ground-mounted systems, the site plan also includes distance from property lines, row spacing, and any trenching for conduit. This documentation is a key part of any system package submitted for permitting or interconnection.

Understanding Diagram Classifications: Energy vs. Panel Focus

A solar panel diagram specifically focuses on the layout, wiring, and components of solar panels within a system. A solar energy diagram encompasses a broader view. This includes energy flow, system connections, performance metrics, and overall solar power generation. Common examples include shading analysis plans, roof layout documentation, electrical one-line schematics, and PV system block diagrams.

Reading Standard Electrical Symbols in Solar Documentation

Solar documentation follows specific standard symbols to maintain clarity and ensure that installers, engineers, and other professionals can easily understand the system layout. Symbols for components are often standardized according to guidelines from organizations like the National Electrical Code (NEC) or the International Electrotechnical Commission (IEC). Knowing how to read these symbols is crucial for anyone involved in solar system design or installation.

Component Symbols and Their Functions

When working with solar documentation, understanding the key components and symbols is essential for designing and installing a solar power system. These technical drawings serve as blueprints that illustrate how all parts of the system connect and function together. Below is an overview of some of the most common components and their representations:

Solar Panels

Symbol: A rectangle with lines or shading representing the photovoltaic (PV) cells inside

Purpose: Solar panels capture sunlight and convert it into electricity. In technical documentation, panels often appear as the primary component and are connected to other systems like inverters and junction boxes. Proper DC connector installation is critical for preventing electrical failures.

Solar Inverters

Symbol: A rectangle, sometimes with a wave or sine wave graphic inside

Purpose: Inverters convert the DC (direct current) electricity generated by the solar panels into AC (alternating current) electricity used by the home or business. In technical drawings, inverters are shown connected to the panels and electrical distribution systems.

Junction Boxes

Symbol: A square or rectangular box with terminals or connections inside

Purpose: Junction boxes play a crucial role by housing the electrical connections between components, such as solar panels and the inverter. They help ensure safe and efficient power transmission. They also protect electrical components from environmental damage.

Solar Batteries

Symbol: A rectangle with a positive (+) and negative (-) terminal

Purpose: Batteries store excess energy generated by the system, allowing for backup power when sunlight is unavailable. In technical drawings, they connect to the inverter and often include charge controllers for managing battery health.

Utility Meters

Symbol: A small circle or rectangle, often with a “meter” label

Purpose: Meters are used to measure the energy production of the solar system (production meter) or the energy consumed from the grid (utility meter). These are crucial for monitoring energy generation and ensuring compliance with net metering programs.

Breakers and Disconnects

Symbol: A small rectangle with lines indicating a switch or circuit

Purpose: In system documentation, breakers and disconnects serve as crucial safety features. They allow installers or homeowners to isolate specific parts of the system for maintenance or emergency shutdowns. They help prevent overcurrent and protect the system from potential damage.

Combiner Boxes

Symbol: A rectangular box with multiple inputs and one output

Purpose: Combiner boxes combine the outputs from multiple solar panels or strings of panels before sending the electricity to the inverter. This simplifies wiring and protects the system by centralizing connections.

Creating Professional Solar Diagrams: A Step-by-Step Process

Creating a clear, accurate solar panel system plan is essential for permitting, inspections, and long-term performance. Whether preparing documentation for homeowners or an on-grid system for AHJs, these steps will help ensure the work is precise and meets code requirements.

Step 1: Gather System Information

Collect the specifications of every component in the system: solar panels, inverter(s), battery storage (if included), wiring sizes, disconnects, and protective devices. This information can usually be found on spec sheets. It forms the backbone of the technical documentation.

Step 2: Choose the Right Solar Energy Diagram Type

Decide what’s required:

- Single-line schematic for showing electrical connections

- Panel layout for roof or ground-mount placement

- Wiring schematic for detailed conductor routes and string configuration

Step 3: Use Standard Diagram Symbols

In the technical drawing, represent components using NEC-compliant electrical symbols. Consistent labeling helps engineers, inspectors, and utility reviewers interpret the design correctly.

Step 4: Map the Solar Strings

Show how many panels are wired in series and parallel. An accurate string configuration ensures the inverter can handle the combined voltage and current. Mark Voc, Isc, and other key values directly on the plan when possible.

Step 5: Add Inverter and Balance-of-System Components

Include the inverter, combiner boxes, fuses, disconnects, and meter locations. For on-grid systems, also show the interconnection point with the utility.

Step 6: Finalize for Permitting and Review

Before submitting, check that the plan matches the engineering calculations and local code requirements. Tools like AutoCAD, design software, or manufacturer-specific programs can streamline the process. Expert services can provide permit-ready plan sets and professional engineering reviews to ensure everything is compliant.

Streamlining Permit Approvals with Quality Documentation

Solar energy documentation is essential for both accurate system installation and a smooth solar permitting process. These visual documents clearly represent how a solar system is designed. They show component placement, wiring paths, and key interconnections. Whether it’s a wiring schematic or a full system plan, these drawings are required by most AHJs to ensure compliance with local building and electrical codes.

High-quality plans reduce the risk of permitting delays by detailing system configurations in a code-compliant format. This includes layout, conduit paths, inverter connections, and grounding. All are crucial for meeting NEC and utility standards. An accurate on-grid system plan also simplifies communication with inspectors and utility engineers. This helps installers get faster approvals and avoid costly revisions. For larger projects, commercial solar design services ensure comprehensive documentation that meets stringent requirements.

Conclusion

Solar energy diagrams serve as the foundation for successful system design, installation, and permitting. From single-line schematics that map electrical connections to shading analysis profiles that optimize panel placement, each type plays a specific role. They ensure code compliance, safety, and maximum energy production. Understanding how to read, create, and apply these technical documents is essential for installers, engineers, and contractors working in the solar industry.

Professional documentation does more than satisfy permitting requirements. It reduces installation errors, improves communication between project stakeholders, and provides long-term documentation for system maintenance and troubleshooting. Whether working on residential rooftop installations, off-grid systems, or complex commercial projects with battery storage, accurate plans streamline the entire process from initial design through final inspection.

Investing time in creating detailed, code-compliant documentation pays dividends throughout the project lifecycle. These plans facilitate faster AHJ approvals and minimize costly field revisions. They ensure systems operate safely and efficiently for decades. As solar technology continues to evolve with rapid shutdown requirements, energy storage integration, and smart monitoring capabilities, the importance of precise technical documentation only grows stronger.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

A single-line diagram provides a simplified, high-level overview of the electrical system using standardized symbols and a single line to represent current paths. It shows major components like arrays, inverters, disconnects, and service panels. A wiring diagram, in contrast, offers granular installation details including specific wire sizes, conductor colors, terminal locations, and exact connection points. The single-line diagram is primarily used for permitting and utility review, while the wiring diagram guides electricians during actual installation work.

No, diagram requirements vary based on system size, location, and AHJ specifications. Residential grid-tied systems typically require a single-line diagram, site plan, and roof layout diagram at minimum. Commercial installations often need additional documentation including string configuration diagrams, monitoring system layouts, and detailed grounding plans. Projects with battery storage require specialized energy storage system diagrams showing BMS components and critical load panels. Always check with the local AHJ to confirm specific diagram requirements before beginning the design process.

Start by using NEC-compliant electrical symbols and following current code articles, particularly NEC Article 690 for PV systems and Article 705 for interconnected sources. Include all required safety elements such as rapid shutdown devices per NEC 690.12, proper grounding per Article 250, and appropriate disconnect locations. Label all components clearly with voltage, current, and power ratings. Consider working with professional engineering services to verify compliance before submission, as code requirements are updated regularly and vary by adoption cycle in different jurisdictions.

Popular design tools include AutoCAD for precision electrical drawings, Helioscope for comprehensive system design with integrated diagram generation, and Aurora Solar for site assessment and layout visualization. PVsyst excels at shading analysis and performance modeling. Many inverter and equipment manufacturers also provide design software with built-in diagram templates. For smaller projects, some installers use SketchUp combined with electrical design plugins. The key is choosing software that generates NEC-compliant symbols, allows for accurate scaling, and exports files in formats accepted by local permitting authorities.

Solar diagrams should be updated whenever system modifications occur, including equipment replacements, capacity expansions, or configuration changes. Even minor updates like inverter upgrades or additional monitoring equipment should be documented with revised diagrams. Maintain as-built diagrams that reflect the actual installed system, as these may differ slightly from original permit drawings due to field conditions. Updated diagrams are essential for future maintenance, troubleshooting, system upgrades, and compliance with evolving safety standards. Store both original permit sets and current as-built documentation for the system's entire operational life.

While templates and symbol libraries can be reused, each solar installation requires unique diagrams tailored to the specific site conditions, equipment specifications, and local code requirements. Roof dimensions, panel layouts, string configurations, and electrical service characteristics vary significantly between properties. Additionally, NEC codes and AHJ standards are regularly updated, meaning older diagrams may not reflect current compliance requirements. Using outdated or non-specific diagrams can result in permit rejections, failed inspections, and potential safety issues. Always create site-specific documentation for each new project.

Solar diagrams serve as essential reference documents for diagnosing system issues and performing maintenance. When inverters fault or production drops unexpectedly, technicians use wiring diagrams to trace electrical connections and identify problem areas. String configuration diagrams help isolate underperforming panel groups. Monitoring system diagrams guide technicians to data loggers and communication equipment when connectivity issues arise. Grounding diagrams are critical when investigating electrical safety concerns. Accurate, accessible diagrams reduce troubleshooting time, prevent diagnostic errors, and ensure maintenance work maintains code compliance throughout the system's operational lifetime.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

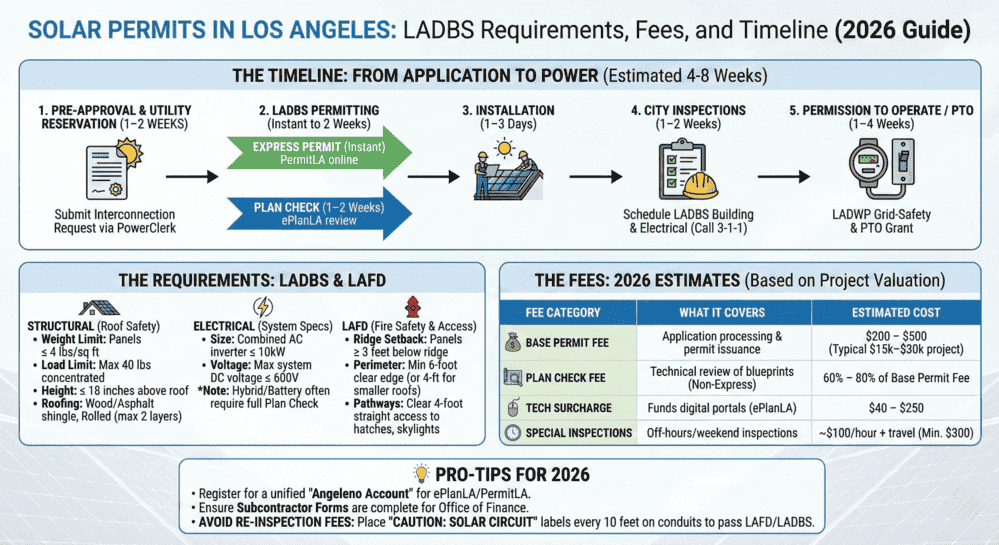

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...