Grounding and bonding errors cause more solar inspection failures than any other code violation. These NEC compliance issues create life-safety hazards, project delays, and costly reinspections even when the physical installation appears flawless.

Key Facts:

- Grounding connects your electrical system to earth, safely dissipating fault current

- Bonding links all metallic components together, eliminating voltage differentials

- Common failures include missing equipment grounding conductors (EGCs), non-UL-listed hardware, and improper conductor sizing

- Cost of failure: A single grounding mistake can delay projects 3-7 days and add $400+ in reinspection fees

NEC Requirements: Inspectors verify compliance with NEC 690.43 (equipment grounding), NEC 690.47 (electrode systems), NEC 250.122 (conductor sizing), and NEC 250.136(A) (bonding protocols).

This guide reveals what inspectors scrutinize during grounding and bonding inspections, why violations occur frequently, and proven methods to pass inspection on the first attempt. Whether you’re installing residential rooftop systems or commercial ground-mount arrays, understanding these critical safety requirements protects your projects from preventable failures.

1. The Critical Importance of Grounding and Bonding in Solar Installations

Grounding and bonding transcend simple NEC compliance tasks. They form the essential safety infrastructure of your system. These components guarantee that any fault current or stray electrical energy follows a low-resistance route back to its origin, eliminating risks of electrocution, fire hazards, and equipment destruction.

Grounding = establishing a connection between your electrical system and earth (providing safe fault current dissipation).

Bonding = linking all metallic components together to eliminate voltage differentials between them.

Within a photovoltaic installation, both elements require precise execution spanning from solar modules and mounting rails through combiner boxes, inverters, and electrical service panels. According to NREL’s solar research, proper grounding systems are fundamental to long-term system reliability and safety.

2. Top Grounding and Bonding Errors That Fail Inspections

Experienced installers still stumble over these NEC requirements. Here’s what inspectors consistently catch:

a. Absent Equipment Grounding Conductors (EGCs)

Omitting EGCs between array sections or neglecting to bond individual racking segments creates incomplete grounding pathways. Critical note: painted aluminum mounting rails provide poor electrical conductivity.

Solution: Deploy UL-certified bonding jumpers or grounding washers to guarantee continuity throughout rail systems. Understanding electrical fundamentals helps prevent these common oversights.

b. Unlisted or Makeshift Bonding Components

Improvised approaches (including self-tapping fasteners or non-certified lugs) trigger immediate inspection failures. All bonding elements require UL 2703 or UL 467 certification.

Solution: Source manufacturer-specified grounding mid clamps, lugs, and jumpers designed for your specific racking configuration. Professional NABCEP-certified installers understand the importance of using only listed components.

c. Improper Grounding Electrode Installation

A solitary 8-foot rod frequently fails resistance standards, particularly in arid or mineral-dense terrain. Inspectors typically mandate dual rods positioned minimum 6 feet apart.

Solution: Test soil resistance values and verify local Authority Having Jurisdiction (AHJ) specifications before finalizing grounding electrode design. Solar permitting requirements vary significantly by jurisdiction.

d. Improper Conductor Gauge Selection

EGCs must conform to NEC 250.122 sizing requirements, determined by overcurrent protection device ratings. Undersized EGCs create both life-safety risks and code infractions.

Solution: Align conductor sizing with OCPD ratings and ensure bonding jumpers meet or exceed minimum requirements. This is a common design mistake that causes permit denials.

e. Unbonded Metal Structures

Mounting rails, junction enclosures, or equipment housings without proper bonding can retain dangerous voltage levels. Inspectors conduct continuity verification across all metallic elements. Any discontinuity results in immediate rejection.

Solution: Perform comprehensive continuity testing across your entire grounding network before inspection. Verify connections between module frames, rails, and grounding electrodes using a digital multimeter. The IEEE Power & Energy Society provides technical standards for proper testing procedures.

3. Essential NEC Code Requirements (2020 / 2023 Editions)

Most jurisdictions currently enforce NEC 2020 or 2023 standards, which provide enhanced guidance for PV grounding and bonding protocols. Critical code sections every solar professional must know:

- NEC 690.43: Equipment grounding and bonding specifications for photovoltaic installations.

- NEC 690.47: Grounding electrode system integration requirements.

- NEC 250.136(A): Bonding protocols for separately derived electrical systems.

- NEC 250.102(C): Sizing requirements for bonding jumpers and grounding electrode conductors.

Mastering these code references maintains compliance standards and establishes credibility with inspectors. For detailed guidance, review our comprehensive solar PV grounding and bonding guide. Expanding your knowledge through essential solar energy books can further strengthen your technical expertise.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

4. Guaranteed Methods for Passing Grounding and Bonding Inspections

- Deploy exclusively UL-certified components for all bonding and grounding applications.

- Apply proper torque specifications. Inspectors verify proper tightening of all lugs and fasteners.

- Clearly identify grounding locations on as-built documentation and single-line diagrams.

- Confirm electrical continuity from every module through to main service grounding point.

- Adhere to racking manufacturer guidelines. These typically define specific bonding hardware placement.

- Capture photographic documentation before concealing conduit runs or junction boxes.

Whether you’re working on off-grid solar systems or grid-tied installations, these inspection methods apply universally. The IEA’s renewable energy reports confirm that proper installation practices directly correlate with system longevity.

5. Case Study: The Cost of Grounding Shortcuts

A 15kW rooftop installation failed inspection on two separate occasions due to “inadequate bonding.” The root cause? The contractor substituted self-drilling screws for proper bonding jumpers between mid-rail sections.

The fix consumed 3 additional days, plus $400 in labor expenses and reinspection charges. A single missing jumper = seven days of lost project revenue.

Understanding how long solar permits take helps contractors avoid these costly delays. Vote Solar’s advocacy work emphasizes streamlined permitting processes that reward compliant installations.

6. The Professional Approach: Leverage Expert Permit Design Services

When you’re managing 10+ solar projects monthly, manually auditing every grounding specification becomes inefficient. Collaborating with a specialized solar permit design firm guarantees your permit packages satisfy NEC grounding and bonding standards before submission.

Professional teams like Solar Permit Solutions engineer with exacting standards, ensuring your construction documents feature:

- Code-compliant grounding pathways per NEC 690 & 250

- Precise conductor sizing calculations

- Jurisdiction-specific grounding specifications

- UL-listed bonding component identification

This approach delivers fewer plan corrections, accelerated permit approvals, and seamless inspection outcomes. For projects in California, our Los Angeles solar permit services specialize in local code compliance.

Modern installations also benefit from advanced components like SolarEdge power optimizers and Eaton electrical panels, which require specific grounding considerations. Whether you’re building a DIY solar system or managing commercial installations, proper grounding remains non-negotiable. For those working with battery storage systems, understanding proper grounding extends to components like LiFePO4 battery packs as well.

Eliminate Inspection Failures: Engineer Correctly From Day One

Grounding and bonding violations are completely preventable when you design with precision.

Allow Solar Permit Solutions’ permit design specialists to engineer your next construction package with compliant grounding layouts, accurate NEC citations, and zero inspection setbacks.

Conclusion

Grounding and bonding violations are completely preventable when you design with precision.

Successful solar installations depend on proper grounding and bonding implementation from the initial design phase. These safety systems aren’t optional enhancements. They’re fundamental requirements that protect lives, equipment, and your project timeline. Every inspection failure due to grounding errors costs you time, money, and professional credibility.

The pathway to consistent inspection success starts with understanding NEC requirements, using exclusively UL-listed components, and maintaining meticulous attention to continuity throughout your entire system. From module frames to service panels, every metallic component must connect through properly sized conductors to create reliable fault current pathways.

Remember that inspectors evaluate more than just visible connections. They verify torque specifications, conductor sizing, grounding electrode adequacy, and complete system continuity. A single missing bonding jumper or improperly sized EGC can derail an otherwise flawless installation. As solar adoption grows and Energy Star initiatives promote sustainable energy, maintaining safety standards becomes increasingly critical.

Additionally, proper end-of-life planning includes understanding EPA regulations for solar panel disposal, which emphasizes the importance of safe system decommissioning. For more solar industry insights and technical guidance, explore our complete blog collection.

Allow Solar Permit Solutions’ permit design specialists to engineer your next construction package with compliant grounding layouts, accurate NEC citations, and zero inspection setbacks.

Request your solar permit design now at www.solarpermitsolutions.com

FAQs:

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Grounding establishes a connection between your electrical system and earth, providing a safe pathway for fault current dissipation. Bonding connects all metallic components together (including module frames, mounting rails, junction boxes, and equipment enclosures) eliminating voltage differentials between them. Both work together to create a complete safety system. Grounding directs fault energy safely to earth, while bonding ensures no potential difference exists between any metal parts a person might touch simultaneously.

The five most frequent grounding violations include: missing equipment grounding conductors (EGCs) between array sections, using non-UL-listed or improvised bonding hardware like self-tapping screws, incorrect ground rod installations that don't meet resistance requirements, undersized conductors that violate NEC 250.122 specifications, and unbonded metallic components such as rails or junction boxes. Inspectors will test continuity across your entire system. Any open circuit results in automatic failure.

The primary NEC sections for solar grounding and bonding are: NEC 690.43 (equipment grounding and bonding requirements for PV systems), NEC 690.47 (grounding electrode system connections), NEC 250.136(A) (bonding of separately derived systems), and NEC 250.102(C) (sizing bonding jumpers and grounding electrode conductors). Most jurisdictions currently enforce either NEC 2020 or 2023 editions. Familiarizing yourself with these specific code references builds inspector confidence and ensures compliance.

Use a digital multimeter to test continuity between module frames, mounting rails, and the grounding electrode before your inspection. Proper continuity should show less than 1 ohm resistance across all metallic components. Test from each module frame to the main service ground, verify all bonding jumpers are secure, and confirm that painted or anodized surfaces have proper penetration through coatings. Inspectors will perform similar tests, so identifying issues beforehand prevents costly reinspections and project delays.

Ground rod requirements depend on soil resistance and local AHJ specifications. A single 8-foot ground rod may suffice if soil resistance measures below code thresholds (typically 25 ohms). However, in dry, rocky, or sandy soil conditions, inspectors commonly require dual ground rods spaced at least 6 feet apart. Always test soil resistance before finalizing your grounding electrode design. Some jurisdictions mandate multiple grounding electrodes regardless of resistance measurements, so verify local requirements before installation.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

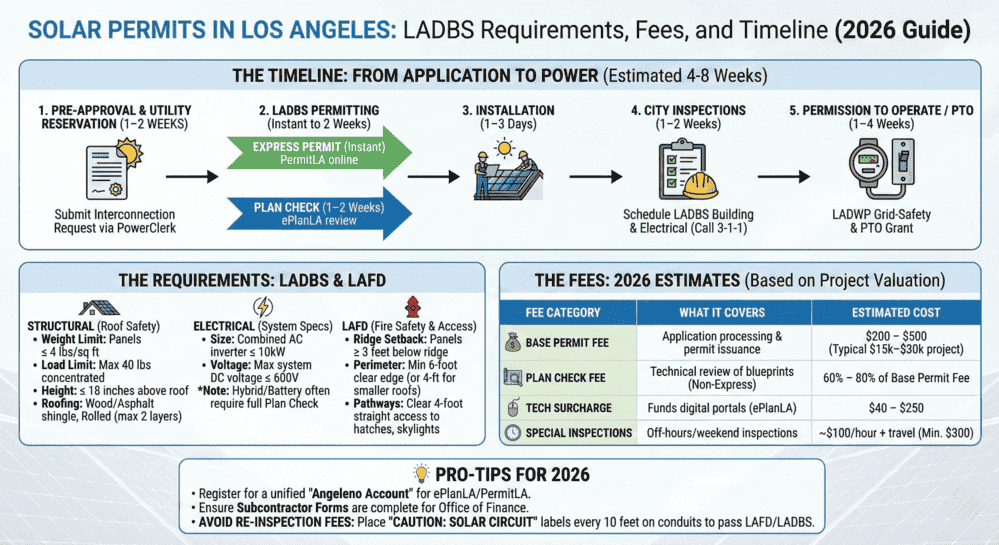

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...