Quick Answer: Solar panels require three types of inspections: a mandatory final inspection for new installations before activation, annual DIY self-inspections, and professional inspections every two years. Key items to check include panel surface condition, electrical connections, mounting integrity, inverter functionality, and system performance.

Inspection Schedule:

- New installations: One-time mandatory inspection (legal requirement before system activation)

- Self-inspections: Annually, after severe weather, or when performance drops

- Professional inspections: Every 2 years for code compliance and safety verification

Essential Inspection Points: Solar panel inspections evaluate surface condition (cracks, dirt), structural mounting security, electrical wiring integrity, inverter operation, shading issues, metal corrosion, roof penetration seals, and energy output performance. New system inspections also verify building permits, electrical schematics, grounding systems, and proper labeling compliance.

Cost and Requirements: Professional inspections cost $150-$300 for residential systems. DIY inspections require no special expertise but familiarity with your system components. New installations must pass inspection to receive permission to operate (PTO) from utility companies.

Each inspection type follows distinct evaluation standards. This detailed guide walks you through every step. From navigating required official assessments to performing personal system checks, you’ll find complete procedures for all inspection scenarios.

How Many Different Solar Panel Inspections Exist?

Many people don’t realize multiple solar panel inspection types exist.

New systems require passing an official evaluation, while established solar installations need regular personal assessments and scheduled professional reviews.

Multiple inspections may seem excessive! However, maintaining panel efficiency and extending their lifespan makes all these evaluations essential.

New Solar Installation: Final Evaluation

The final evaluation stands as a non-negotiable requirement for new solar installations. Your system must remain dormant (completely unusable) until this critical checkpoint is cleared.

After your installation crew completes their work, a certified evaluator arrives to verify compliance. Their mission? Confirm your setup adheres to every building regulation, electrical standard, and safety protocol on the books.

The evaluator meticulously examines electrical connections, structural mounting systems, and physical components while cross-referencing your paperwork trail: blueprints, permits, and technical specifications.

Pass the evaluation, and you’re cleared for activation. Fail, and you’ll address the deficiencies before scheduling a follow-up visit.

Regular Personal Assessments for System Upkeep

Personal system assessments form the backbone of sustained solar performance. Yes, solar panels rank among the lowest-maintenance energy systems available, but “low-maintenance” doesn’t translate to “no-maintenance.”

Regular checkups keep your system humming at peak capacity while catching minor issues before they balloon into expensive repairs.

Your assessment routine should encompass every major component: the panels themselves, electrical connections, mounting hardware, and battery banks if your system includes storage.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Professional Solar Evaluation Services

Bringing in outside expertise periodically adds tremendous value to your maintenance strategy.

Professional evaluation services are widely available and straightforward: a NABCEP-certified technician visits your property to conduct an exhaustive system analysis.

The service costs money, certainly. But the investment pays dividends. These professionals possess trained eyes that spot deterioration, code violations, and performance issues the average homeowner will miss. Many also handle repairs on-site, resolving problems immediately.

Here’s another consideration: the National Electric Code evolves on a three-year cycle, introducing fresh requirements with each revision. Your once-compliant system can silently drift out of compliance without periodic professional verification.

Combine annual self-checks with professional evaluations every two years for optimal results. However, when your system’s output plummets unexpectedly and your personal inspection reveals no obvious culprit, skip the waiting period and call the professionals immediately.

Why Solar Panel Evaluations Matter

Solar panel evaluations protect two things: your system’s efficiency and everyone’s safety.

Solar installations may appear straightforward, but they’re intricate assemblies of interconnected components (especially electrical elements) that can degrade or fail. A single malfunctioning component doesn’t just slash your energy production; it can spark fires or electrocute anyone who ventures too close.

Beyond performance and safety, damaged systems frequently violate building codes and safety regulations. Code violations open you to fines, legal complications, and potentially severe penalties.

Solar Installation Final Evaluation Checklist

The evaluation process for your newly installed system is more manageable than it appears. Professional solar developers typically shepherd clients through the entire evaluation sequence. It’s part of their solar design services package.

Reputable developers ensure code compliance from the design phase forward, so passing inspection should be straightforward.

Still, knowing what evaluators scrutinize helps you prepare. Here’s the comprehensive breakdown:

Required Documentation

- System blueprints with complete electrical schematics

- All manufacturer warranties and system guarantees

- Complete permit documentation

- Component inventory with manufacturer details

Photovoltaic Modules and Arrays (Ground & Roof-Mounted)

- Installation matches approved blueprints precisely

- The design is clean, professional, and performance-optimized

- Surrounding vegetation won’t shade or obstruct arrays

- All modules are intact without cracks or damage

- Module model numbers align with approved plans

- Warranty coverage meets minimum requirements

- All module connections are properly tightened and secured

- Building penetrations are sealed and fire-resistant

- Metal components and surfaces are correctly grounded

- All metals are protected against corrosion

- Aluminum components avoid direct concrete contact

Roof-Mounted Arrays (Specific Requirements)

- Arrays are securely anchored with appropriate standoff height per fire codes

- Roof penetrations are watertight and structurally sound

- Electrical conductors are elevated above roof surfaces

- Mounting hardware is anchored into structural rafters (when specified)

Inverter and Electrical Components

- The inverter location matches plans and allows easy access

- The inverter model corresponds to approved specifications

- The inverter is factory-new, adequately warranted, and CEC-certified

- Wire gauges and conduit sizes match electrical plans

- All conduit is properly supported and secured

- Wiring is professionally organized, properly protected, and not readily exposed

- String overcurrent devices are DC-rated and properly sized

- DC disconnect switch is DC-rated and easily accessible

- AC disconnect is readily accessible

- All junction boxes are accessible and meet location-specific housing requirements

- Grid connection is established and operational

- Internet connectivity is functional (if system requires remote monitoring)

Labeling Requirements

- All system components display required identification labels

- Site layout diagram is posted at meter and disconnect locations

- DC disconnect displays proper PV power source specifications

- AC connection point shows correct labeling

- All outdoor labels are weatherproof and UV-resistant

- Emergency contact information and maintenance instructions are clearly posted

Personal Assessment Checklist

Let’s dive into the personal assessment checklist. Relax: you don’t need an engineering degree or solar expertise to handle this. However, becoming intimately familiar with your setup makes the process significantly easier.

When your solar system goes live, invest time understanding each component: its function, normal operation, and baseline appearance. Consider photographing everything. These images become invaluable reference points when determining whether something has deteriorated or sustained damage.

Schedule personal assessments:

- Annually at minimum

- Immediately after severe weather (storms, hail, high winds)

- When system output unexpectedly declines

Visual and Physical Inspection Points

Solar Panel Surface Condition

- Do panel surfaces need cleaning? (Dust, pollen, bird droppings, or film accumulation)

- Has the panel glass developed chips, cracks, or fractures?

- Is the aluminum frame intact without dents, bends, or warping?

Shading and Obstruction Analysis

- Are nearby objects casting shadows on your panels? (New construction, grown trees, installed equipment)

- Has vegetation grown tall enough to block sunlight or cover panel surfaces?

- Is debris scattered on or around the array? (Fallen branches, leaves, nests)

Structural Integrity Check

- Are mounting brackets and rail systems tightly secured? Test for movement or wobbling

- Does the rear panel surface show damage? (Often overlooked but critical)

- For rooftop installations, is the underlying roof structure sound and undamaged?

Electrical System Examination

- Is all visible wiring intact, properly secured, and firmly attached?

- Do any wires show fraying, exposed copper, or damaged protective conduit?

- Are electrical conductors properly fastened without sagging or tension?

Component Condition Assessment

- Have metal components developed rust, oxidation, or corrosion?

- Are roof penetrations sealed tightly against water intrusion?

- Is the inverter powered on and displaying normal operational readings?

- Is your utility meter connection active and functioning correctly?

Performance and Compliance Verification

- Is your system generating its typical energy output, or has production dropped noticeably?

- Are all required warning signs, labels, and instructional placards present and readable?

Taking Action on Inspection Findings

Handle basic maintenance tasks yourself: cleaning panels, clearing debris, or trimming encroaching vegetation.

For anything involving structural damage, electrical issues, or component failure, stop immediately. Contact certified professionals right away. These repairs require specialized knowledge, proper tools, and adherence to electrical codes that DIY approaches can’t safely satisfy.

Pro Tip: Create a simple inspection log documenting each assessment date, findings, and actions taken. This record helps track system health over time and proves invaluable when discussing performance issues with professionals.

Tools for Solar Panel Assessments

Solar Monitoring Systems

Solar monitoring systems deliver exceptional value by providing deep visibility into your array’s performance and flagging anomalies before they become serious problems.

Installation flexibility is a major advantage. These systems integrate seamlessly with new installations or retrofit onto existing arrays without major modifications.

The technology relies on sensors that transmit data to smartphone apps or computer software for real-time monitoring. This connectivity requires wifi or cellular service, which presents challenges for arrays in remote locations with limited signal coverage.

Hardwired monitoring alternatives exist for signal-challenged locations, though they command higher purchase prices and installation costs. Power optimizers offer integrated monitoring capabilities alongside performance benefits.

Drone Technology for Solar Panel Assessments

Drone inspections are rapidly gaining traction, especially for expansive commercial installations and geographically isolated arrays.

These aerial assessments deploy remotely piloted drones equipped with sophisticated technology: artificial intelligence processing, thermal imaging cameras, and high-resolution RGB sensors to comprehensively analyze panel condition and performance.

The drone’s precision maneuverability reaches every section of your array without human presence on-site. Advanced programming enables detection of defects and degradation that human inspectors frequently overlook.

Drone inspection technology doesn’t demand enormous investment. Even basic consumer drones with standard cameras can execute valuable visual assessments at a fraction of professional inspection costs.

This approach proves particularly valuable in hazardous conditions: post-storm inspections when weather remains dangerous or rooftop array assessments where fall risks exist. Drones eliminate human risk entirely while delivering thorough examination results.

When to Schedule Professional System Inspection

Professional inspections should occur biennially as standard maintenance protocol.

Beyond the regular schedule, immediately arrange a professional inspection when:

- System energy production drops noticeably without obvious cause

- Your personal assessment uncovers damage, defects, or concerning conditions

- Your system completely stops generating power

Preparing for Professional Inspection Services

Preparation for professional inspections is straightforward. These steps ensure efficient, productive inspection visits:

Document Preparation:

Compile all system documentation: original installation blueprints, permit records, warranty information, and previous inspection reports. Having everything organized saves time and provides inspectors with critical reference material.

Site Access:

Clear pathways to all system components. Remove obstructions blocking access to panels, inverters, disconnects, and electrical equipment. Inspectors need unimpeded access to perform thorough examinations. For residential solar design configurations, ensure attic or roof access is readily available.

Question Preparation

List specific concerns or questions before the inspector arrives. Address performance anomalies, unusual sounds, error messages, or anything that seems abnormal. Clear communication ensures inspectors focus on your specific concerns.

During the Inspection

Communicate all concerns directly to the inspector. Don’t assume they’ll automatically discover every issue. Many inspection services offer immediate repair capabilities, resolving problems during the same visit and eliminating the need for return appointments.

After inspection completion, the professional will review findings, explain necessary repairs, and provide recommendations for maintaining optimal system performance going forward. Understanding common design mistakes that cause permit denials helps prevent future compliance issues.

Conclusion

Solar panel inspections aren’t optional luxuries. They’re essential practices that protect your investment, maximize energy production, and ensure safe operation for years to come.

Whether you’re navigating the mandatory final evaluation for a new installation, conducting your annual personal assessment, or scheduling biennial professional reviews, each inspection type serves a distinct purpose in your system’s lifecycle. New installations require official approval before activation, while ongoing assessments catch problems early when they’re easiest and most affordable to fix.

The good news? You don’t need technical expertise to maintain your solar array effectively. Armed with this comprehensive checklist and a basic understanding of your system’s components, you can handle routine visual inspections confidently. For those considering DIY solar installation, understanding inspection requirements is crucial from the planning phase. Combine these regular self-checks with professional evaluations every two years, and you’ll keep your panels operating at peak efficiency while avoiding costly surprises.

Remember: solar panels may be low-maintenance, but they’re not no-maintenance. A few hours invested in inspection annually pays dividends through sustained performance, extended equipment lifespan, and peace of mind knowing your system operates safely and efficiently. Whether you have a grid-tied system or off-grid solar setup, regular inspections remain essential. When issues arise beyond your expertise (electrical problems, structural damage, or unexplained performance drops), don’t hesitate to call certified professionals.

Your solar investment deserves proactive care. According to recent renewable energy research, properly maintained systems can operate efficiently for 25-30 years or longer. The International Energy Agency projects continued solar growth, making proper maintenance practices increasingly important for maximizing long-term returns. Start implementing these inspection practices today, and your system will reward you with reliable, clean energy for decades. For professional support with solar permits in Los Angeles or anywhere else, expert assistance ensures compliance from day one.

Understanding solar permitting processes and maintaining code compliance protects your investment throughout its operational life. Organizations like Vote Solar advocate for streamlined permitting and inspection processes that benefit homeowners nationwide. Proper grounding and bonding practices, verified during inspections, prevent electrical hazards and ensure safe operation.

For those seeking deeper knowledge, exploring essential solar energy books provides valuable background. Additionally, staying informed through resources from the IEEE Power & Energy Society keeps you current on technical standards. When your system eventually reaches end-of-life, following EPA guidelines for solar panel disposal ensures environmentally responsible recycling.

Finally, don’t overlook available incentives. Energy Star programs may offer rebates for efficiency upgrades discovered during inspections. For more information and expert guidance on all aspects of solar system maintenance, visit our blog regularly for updates and tips. Solar Permit Solutions offers comprehensive design, permitting, and support services that simplify solar ownership from installation through decades of operation.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Solar panels should undergo personal assessments at least once annually, with professional inspections scheduled every two years. Additionally, inspect your system immediately following severe weather events like hailstorms, high winds, or heavy snow. If you notice unexpected drops in energy production, conduct an immediate inspection regardless of your regular schedule. New installations require mandatory official inspection before activation.

A comprehensive solar panel inspection examines multiple system components: panel surface condition (cracks, chips, dirt accumulation), structural mounting integrity, electrical connections and wiring, inverter functionality, shading or obstruction issues, metal component corrosion, roof penetration seals, and overall system performance metrics. Professional inspections also verify compliance with current electrical codes and building regulations, which evolve every three years.

You can and should perform basic visual inspections yourself annually. These DIY assessments check for obvious issues like debris accumulation, visible damage, loose mounting hardware, and performance drops. However, professional inspections remain necessary every two years because certified technicians identify code violations, electrical hazards, and subtle degradation that untrained eyes miss. Always call professionals for electrical repairs, structural damage, or when DIY inspection reveals concerning issues.

Several warning signs indicate immediate inspection needs: sudden drops in energy production compared to historical performance, visible physical damage (cracks, chips, or broken glass), loose or damaged wiring, inverter error messages or unusual readings, burnt smells near electrical components, water stains around roof penetrations, rust or corrosion on metal parts, and excessive shading from overgrown vegetation. After severe weather events, always inspect regardless of visible damage.

Professional solar panel inspection costs typically range from $150 to $300 for residential systems, though prices vary based on system size, location, and inspection complexity. Many solar installation companies include free or discounted inspections for systems they installed. Some inspection services bundle repairs with the evaluation, potentially saving money on return visits. While this represents an upfront expense, professional inspections prevent costly repairs by catching problems early and ensure your system maintains peak performance, maximizing your return on investment.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

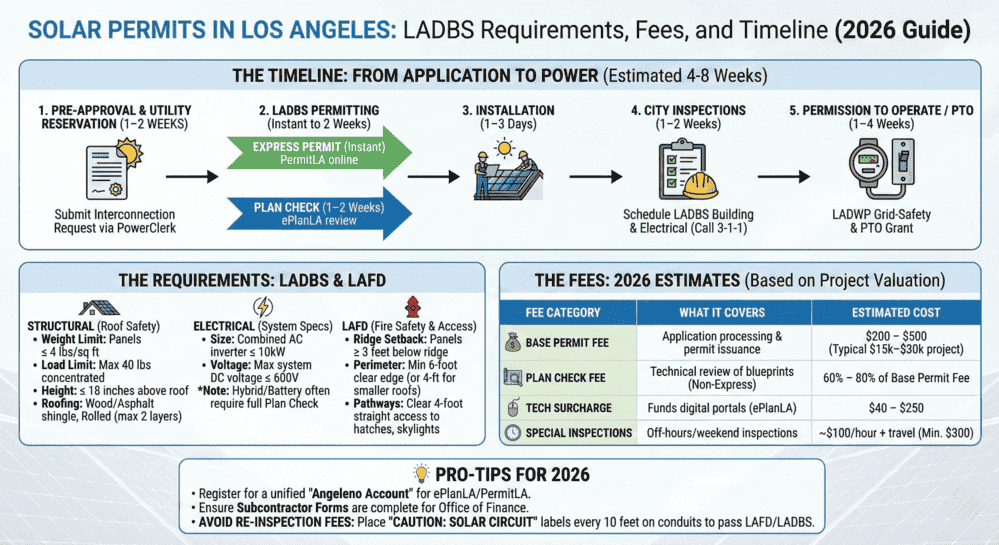

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...