Solar panels are designed to withstand extreme weather conditions and typically last 25 to 30 years with proper maintenance. Modern photovoltaic (PV) modules undergo rigorous testing to meet international standards like IEC 61215, which includes resistance to hail impacts at 50-70 mph, heavy snow loads, and high wind pressures from hurricanes.

Key Solar Panel Durability Facts:

- Expected Lifespan: 25-30 years with warranties guaranteeing 80-85% output after 25 years

- Hail Resistance: Certified to withstand 1-inch ice balls at high speeds (50-70 mph)

- Temperature Impact: Performance drops 0.2-0.5% per degree Celsius above 77°F (25°C)

- Wind Resistance: Engineered to meet local hurricane and high-wind building codes

- Snow Load Capacity: Mounting hardware rated for hundreds of pounds per square foot

- Waterproofing: Panels are completely weather-sealed; water risks mainly affect electrical connections

Panel Durability by Type:

- Monocrystalline: Highest durability and efficiency, best for long-term performance (30+ years)

- Polycrystalline: Moderate durability, more affordable, slightly faster degradation

- Thin-film: Lower overall robustness but performs well in high heat and low-light conditions

- Bifacial: High efficiency with dual-sided energy capture, durability depends on installation quality

While panels themselves resist extreme weather through tempered glass, aluminum frames, and protective encapsulation layers, the most vulnerable components are inverters and electrical connections. Professional Solar Permit Solutions installation following local building codes ensures systems withstand regional climate challenges including flooding, heavy snow, and severe storms.

Different Panel Types Offer Varying Levels of Durability

Various types of PV modules serve residential solar and commercial solar power projects, each with distinct durability characteristics.

Monocrystalline Solar Panels

Monocrystalline panels feature construction from a single silicon crystal, creating their distinctive sleek black appearance. These panels deliver high efficiency and strong resilience, often outlasting polycrystalline alternatives. Their uniform structure provides exceptional resistance to wear, stress, and weather-related damage, maintaining peak performance for decades.

Polycrystalline Solar Panels

Polycrystalline panels consist of multiple silicon crystals, producing their characteristic blue appearance. These panels typically deliver lower efficiency and shorter expected lifespans compared to monocrystalline options, though they offer more affordable pricing. Manufacturing through melted silicon fragments results in slightly faster degradation over time. However, homeowners seeking budget-friendly solar solutions find them a reliable choice.

Thin-Film Solar Panels

Thin-film panels utilize semiconductor material layered onto surfaces like glass or metal. Known for flexibility, lightweight design, and semi-transparent options, they suit specific niche applications. While typically less efficient than crystalline panels, they perform well in low-light conditions and high temperatures.

However, their overall robustness typically falls below monocrystalline panels, resulting in shorter lifespans. This makes them less suitable for homeowners prioritizing multi-decade energy production.

Building-Integrated Photovoltaics (BIPV)

BIPV systems integrate solar technology with building materials like solar roof tiles or transparent solar windows. They generate renewable energy while functioning as structural building components. System longevity depends heavily on specific materials and integration methods. While some BIPV options deliver long-lasting performance, others exhibit shorter lifespans compared to traditional rack-mounted panels.

Bifacial Solar Panels

Bifacial panels capture sunlight from both front and back surfaces, utilizing reflected light from below to boost energy production. This design generates more power than traditional panels, especially when installed over bright surfaces like white roofs or light-colored pavement. While known for high efficiency, long-term sturdiness depends on environmental conditions and precise installation quality.

Understanding Panel Construction: What Makes Them Last

Solar investments require assurance that systems withstand years of exposure. Modern modules achieve robustness through multiple highly engineered layers designed to withstand elements and maintain efficiency for decades.

Critical components providing this protection include:

Photovoltaic Cells: These silicon cells function as the power core. They lack intrinsic ruggedness, requiring careful protection by outer layers to ensure reliable, long-term performance.

Encapsulation Layers: These protective sheets (often EVA or similar polymers) seal around PV cells. Their primary function creates a watertight, protective barrier preventing moisture infiltration, a leading cause of panel failure and long-term degradation.

Backsheet: This essential layer on the panel underside insulates electrical wiring and components. It shields against humidity and UV radiation, factors severely compromising panel toughness over time.

Tempered Glass: The front surface features specialized, low-iron tempered glass. This material delivers exceptional strength, shielding against weather hazards like hail, wind-blown debris, and flying stones, directly enhancing immediate resilience.

Aluminum Frame: The sturdy frame, typically lightweight aluminum, provides mechanical strength and structure needed to absorb physical stress. It secures panels to racking systems, ensuring stability under high wind loads and heavy snow.

Temperature Effects: Why Heat Reduces Performance and Lifespan

Rising temperatures present solar panels with a dual challenge impacting both immediate power output and long-term durability. High heat causes efficiency losses, reducing electricity production as temperatures climb above optimal levels. This occurs because elevated temperatures interfere with semiconductor materials inside photovoltaic cells.

Quantifying Temperature-Related Power Loss

Understanding this immediate effect requires examining the temperature coefficient. This metric measures the percentage by which panel power output decreases for every degree Celsius panel temperature rises above 77°F (25°C).

Most panels have coefficients between -0.2% and -0.5% per degree Celsius. While a half-percent drop appears small, blistering hot days translate to noticeable energy production reductions.

Material Selection for Hot Climate Performance

Heat performance varies significantly between panel types. Selecting systems for high-temperature regions makes material science critical:

- Thin-film solar panels generally perform best in hot weather due to lower temperature coefficients.

- Monocrystalline panels typically surpass polycrystalline panels in heat resilience, making them preferred for high-temperature installations prioritizing efficiency.

Chronic Heat Exposure and Component Degradation

Beyond daily output reduction, prolonged high heat exposure affects long-term durability through thermal stress. Extreme temperatures cause various panel materials (silicon, glass, encapsulation layers, and copper wiring) to expand and contract constantly. Over two or three decades, this cyclical stress leads to worn soldered connections, microcracks in cells, and backsheet seal degradation.

Choosing high-quality panels specifically designed for heat resistance defends against both daily energy loss and long-term thermal degradation.

Solar Permit Solutions

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

How Solar Systems Withstand Harsh Weather Conditions

High-quality photovoltaic modules undergo rigorous testing to withstand most extreme conditions, though maintaining long-term performance requires proper installation and owner maintenance.

1. Structural Resistance: Wind and Snow

Tempered glass and robust aluminum frames resist physical forces effectively. Panel testing standards mandate resistance to significant loads, ensuring properly installed systems endure heavy snow and strong winds without issue.

When comparing brands, checking structural ratings proves essential. Independent testing resources like the PVEL PV Module Reliability Scorecard provide rigorous testing data for evaluating brand performance under long-term stress.

2. The Problem of Soiling (Dirt and Debris)

While structurally tough, panel performance suffers immediately from surface buildup. Dust, dirt, pollen, and particles block sunlight, directly reducing electricity generation. This issue, known as soiling, occurs particularly in dry, dusty areas or near industrial sites.

Beyond simple output reduction, persistent soiling causes hot spots. These localized high-temperature areas occur when completely shaded cells connect to producing cells. Over time, hot spots damage solar cells and compromise overall panel durability.

Maintenance Tip: Regular cleaning maintains efficient system operation. Using soft brushes and non-abrasive cleaning solutions removes buildup without scratching glass. Safe cleaning protects panel efficiency and extends lifespan, avoiding common DIY mistakes.

3. Rain, Storms, and Surge Protection

Heavy rain may temporarily reduce energy production but often proves beneficial, naturally washing away dirt and dust.

The main durability threat during storms comes from lightning and accompanying power surges, not rain itself. While panels feature inherent weatherproofing, the highly sensitive solar inverter (system brain) remains vulnerable to electrical surges.

Durability Strategy: Maintaining overall system longevity in storm-prone areas requires ensuring inverters have proper shelter and protection from high-quality surge protectors.

Snow Coverage: Temporary Blockage, Not Structural Risk

Snow presents temporary efficiency problems rather than long-term durability threats. Complete snow coverage blocks sunlight from reaching photovoltaic cells, halting energy production.

However, panels demonstrate remarkable structural strength, handling significant snow loads. This structural capacity receives verification during installation permitting, where systems must follow local building codes and rigorous durability standards.

Passive Snow Removal: In heavy snowfall areas, solar panels install at specific tilt angles helping snow slide off naturally as temperatures rise or panels generate heat.

Safe Clearance: When clearing snow becomes necessary for maintaining peak energy production, extreme caution prevents scratching glass surfaces, as damage compromises long-term panel durability. Using soft brushes or solar-specific snow removal tools provides the safest approach. Accessing rooftop panels requires prioritizing safety and taking extra precautions preventing slips in icy conditions.

High Wind Performance and Hurricane Readiness

Modern solar systems handle severe dynamic weather, including strong winds and high wind loads from hurricanes.

Panel designs undergo rigorous evaluation under international standards like IEC 61215, specifically testing intense wind pressure resistance. Panels meeting these high standards endure severe storms without mechanical damage.

Hurricane or high-wind-prone regions require solar permitting compliance with specific wind resistance regulations. Local requirements ensure mounting systems and panels receive secure ratings for local climate risks. Working with experienced installation teams ensures systems meet all necessary engineering guidelines for durability and safety.

Professional solar services help when systems malfunction. Whether inverters fail, panels underperform, or inspections become necessary for insurance or resale purposes, professional services provide nationwide support.

Protecting Solar Equipment in Areas With Flooding Risk

While solar panels themselves feature waterproof construction, long-term system durability in flood-prone areas depends on protecting sensitive electrical components and wiring from water damage.

Safeguarding Electrical Infrastructure

Durability in flood zones requires meticulous installation practices, particularly regarding wiring and enclosures. Proper conduit routing and careful electrical installation prove critical for ensuring safety and performance where water presents recurring threats.

Primary risk mitigation strategies include:

Weatherproof Enclosures: All sensitive electrical components and connections, including wiring terminations and essential electronics, must feature completely waterproof design or housing in high-rated weatherproof enclosures.

Elevated Installation: Conduit routing receives careful planning to avoid low-lying, flood-prone areas. When necessary, additional measures like elevated inverter mounting or physical flood barriers implement protection, keeping electronics safely above anticipated flood lines.

Strict adherence to local building codes and regulations specific to solar panel installations in flood-prone areas remains crucial. These codes ensure longevity and safe system operation, often dictating minimum elevation requirements for critical hardware.

What To Check After Severe Weather Events

Severe weather events (hurricanes, high winds, heavy hail, and ice storms) test system structural durability limits. After major events, careful assessment ensures system safety and functionality, with personal safety as absolute first priority.

1. Prioritizing Personal Safety

Never attempt solar array inspection when unsafe conditions exist.

Check for Hazards: Before approaching houses or roofs, identify dangers like downed power lines, sharp metal debris, or unstable tree limbs.

Roof Conditions: Never climb onto wet, icy, unstable roofs, or during persistent high winds.

Call a Professional: When damage appears suspected but safe ground-level inspection proves impossible, or systems remain energized, immediately contact licensed solar professionals for safe assessment rather than attempting DIY repairs.

2. Signs of Solar Panel Damage (Visual Check)

From safe ground distances, visually inspect entire arrays for these common physical distress signs:

- Cracked or Shattered Glass: The protective glass surface provides the first defense line.

- Bent or Damaged Frames: Look for visible aluminum frame warping securing panels to racking.

- Loose or Missing Panels: Shifted or detached panels pose severe hazards.

- Debris on the Array: Large debris like fallen branches causes point pressure damage even without fully broken glass.

- Racking Integrity: Look for bent or loosened mounts and rail connections.

When observing or suspecting damage, avoid self-repair attempts. As precaution, when readily accessible disconnect switches exist, shut down systems until qualified technicians perform full evaluations.

Conclusion

Solar panel durability allows systems to handle extreme weather, and adding battery storage helps maintain power during outages. After Hurricane Maria, tens of thousands of solar systems with batteries installed in Puerto Rico proved solar resilience in tough conditions.

Well-designed solar systems improve durability with strong mounting, weather-resistant materials, and monitoring systems detecting issues early. Proper electrical design helps solar panels stay secure and perform efficiently even in harsh weather. Contact us for professional solar design services.

FAQs

This section addresses common and specialized questions regarding expected lifespan, maintenance, and resilience of solar photovoltaic (PV) systems under various environmental conditions.

Performance Warranty (or Power Output Warranty): Guarantees panels maintain certain minimum power output over time. For example, guaranteeing 90% rated power after 10 years and 80% after 25 years.

How does snow load affect the system’s longevity?

All racking and panel systems receive engineering and installation based on maximum predicted snow loads for local regions. Installers use mounting hardware rated to handle hundreds of pounds per square foot. While deep snow may temporarily cover panels and stop energy production, structural damage remains highly unlikely unless improper installation occurred.

- Degraded wiring insulation

- Loosening racking bolts and mounting hardware

- Inverter issues

- Cell damage (micro-cracks) invisible to naked eyes, often detected using thermal imaging

What are “micro-cracks,” and how do they affect durability?

Micro-cracks are tiny, hairline fractures within silicon cells, often caused by thermal stress (rapid temperature changes) or physical trauma (accidental dropping during transport or installation). Over time, these cracks grow, causing affected cell portions to become inactive (“hot spots”), reducing overall panel power output and shortening effective life.

Need Solar Permit Plans?

Professional, permit-ready solar plan sets delivered fast. Residential and commercial projects across all 50 states.

Frequently Asked Questions

Most modern solar panels operate effectively for 25 to 30 years. Standard performance warranties typically guarantee panels still produce at least 80% to 85% of original output after 25 years. Actual physical system lifespans often exceed this with proper component maintenance.

Product Warranty (or Equipment Warranty): Covers physical panels against defects in manufacturing, materials, and workmanship (frame failure, glass cracking, or defective junction boxes). These typically span 10 to 12 years. Performance Warranty (or Power Output Warranty): Guarantees panels maintain certain minimum power output over time. For example, guaranteeing 90% rated power after 10 years and 80% after 25 years.

Yes. Modern solar panels undergo design and rigorous testing standards to withstand significant impact. Panels receive IEC 61215 certification, including hail tests where ice balls approximately 1 inch (25mm) in diameter fire at panels at high speeds (around 50-70 mph). However, extremely large, jagged, or dense hail stones can still cause damage.

Panels themselves feature completely waterproof and weather-sealed design against rain, snow, and ice. Aluminum frames, glass, and backing materials create sealed, durable units. Water risks mainly concern electrical connections and components behind and under panels, making proper conduit routing and sealed enclosures essential.

All racking and panel systems receive engineering and installation based on maximum predicted snow loads for local regions. Installers use mounting hardware rated to handle hundreds of pounds per square foot. While deep snow may temporarily cover panels and stop energy production, structural damage remains highly unlikely unless improper installation occurred.

In most residential environments, natural rain sufficiently washes away common dirt, pollen, and debris. Cleaning typically becomes necessary only with heavy buildup (thick drought dust or bird droppings) noticeably impacting performance. When cleaning, use water and soft brushes, never abrasive chemicals or high-pressure washers.

Beyond post-storm inspections, inspections every three to five years prove advisable. Professionals check invisible issues including: Degraded wiring insulation, Loosening racking bolts and mounting hardware, Inverter issues, Cell damage (micro-cracks) invisible to naked eyes, often detected using thermal imaging.

Micro-cracks are tiny, hairline fractures within silicon cells, often caused by thermal stress (rapid temperature changes) or physical trauma (accidental dropping during transport or installation). Over time, these cracks grow, causing affected cell portions to become inactive (hot spots), reducing overall panel power output and shortening effective life.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

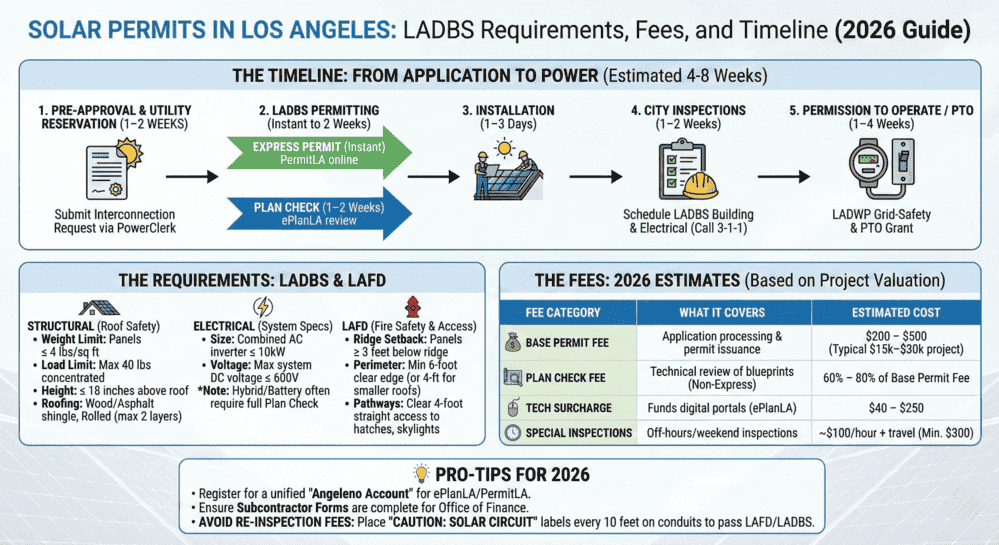

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...