The EG4 18kPV All-In-One Hybrid Inverter is a 12 kW continuous output, 18 kW solar input hybrid inverter with UL 1741 SB certification, NEMA 4X outdoor rating, and built-in rapid shutdown compliance for NEC 2020. Key specifications for solar permit approval include:

- Solar Input: 18 kW maximum across 3 MPPTs, 100-600 VDC range

- AC Output: kW at 240 V continuous, 50 A rated current

- Battery: 48VDC nominal, 250A max charge/discharge, lithium or lead-acid compatible

- Certifications: UL 1741 SB, IEEE 1547:2018, California Rule 21, CEC Listed

- Backup Power: <20 ms transfer time, 14.7 kW peak with PV

- Physical: 34.3 x 20.5 x 11.2 inches, 121.25 lbs, IP65 rated

This inverter supports grid-tied, off-grid, and hybrid operation modes with three interconnection methods: back fed breaker (NEC 705.12), supply-side tap, and feeder tap for whole-home backup. The system requires ONE ground-neutral bond at the main service panel and includes an integrated RSD transmitter that reduces PV voltage below 30V within 30 seconds.

For professional residential solar design assistance and permit documentation, comprehensive plan sets can significantly accelerate your AHJ approval timeline.

Key Certifications & Standards for Permit Approval

Solar permit applications live or die based on equipment certifications. The EG4 18kPV carries comprehensive listings that satisfy requirements across all U.S. jurisdictions, including California’s stringent Rule 21 standards. Understanding AHJ solar requirements is essential for first-time approval success.

Safety Certifications Required on Plan Sets

The following certifications should be clearly documented on your plan set cover sheet and solar single-line diagram:

- UL 1741 SB (Rule 21 compliant) – The primary safety standard for grid-interactive inverters

- ETL & cETL Listed – Third-party verification of safety compliance for U.S. and Canadian markets

- CSA 22.2.107.1 and CSA 22.2.330 – Canadian Standards Association electrical safety compliance

- UL 9540 – Energy Storage System certification for battery-integrated configurations

- CEC Listed – California Energy Commission equipment listing for state incentive programs

Grid Connection Standards

The EG4 18kPV meets all major U.S. interconnection requirements:

- IEEE 1547:2018 and IEEE 1547.1:2020 – The national standards for distributed energy resource interconnection

- California Rule 21 Phase I, II, and III – Full compliance with California’s advanced inverter function requirements

- Hawaii Rule 14H – Specific compliance for Hawaii Electric Company interconnection requirements

NEC Code Compliance Features

Built-in safety features address critical NEC 2020 requirements. For detailed compliance guidance, review our solar panel safety codes guide:

- Rapid Shutdown (RSD) per NEC 2020:690.12 – Integrated transmitter module reduces PV conductor voltage to less than 30V within 30 seconds

- AFCI Protection per NEC 2020:690.11 / UL1699B – Arc-fault circuit interrupter capability for fire prevention

- GFDI Compliance per NEC 2020:690.41(B) – Ground-fault detection and interruption for system safety

Environmental Ratings

Understanding environmental limitations is critical for installation planning and permit approval:

- NEMA 4X / IP65 Outdoor Rating – Suitable for outdoor installation with protection against water, dust, and corrosion

- Operating Temperature Range: -25°C to 60°C (-13°F to 140°F) with derating above 45°C (113°F)

- Altitude Limitation: Less than 2,000 meters (6,562 feet) above sea level

- Relative Humidity: 0-100% operating range

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Electrical Specifications for Plan Set Line Diagrams

Accurate electrical specifications are the foundation of any successful solar permit application. The following data points must appear on your single-line diagram and load calculations.

AC Input Data (Grid Side)

These specifications define how the inverter connects to and interacts with the utility grid:

AC Grid Output Data

Grid output specifications determine back feed capacity and interconnection requirements. Learn more about how solar panels connect to the grid:

Backup/UPS AC Output Data

These specifications are critical for sizing critical loads panels and understanding backup capacity:

PV Input Data (Solar Array Side)

Understanding PV input specifications is essential for proper string sizing and array design:

Important String Design Notes: MPPT-1 accepts two parallel strings that must be identical (same model, brand, and quantity of panels). MPPT-2 and MPPT-3 each accept one string and can vary from each other and from MPPT-1. Always verify the lowest ambient temperature at the installation location and apply temperature correction factors to ensure maximum string voltage never exceeds 600V.

Battery Data

Battery specifications affect system sizing and safety documentation:

NEC Interconnection Methods & Breaker Sizing

Selecting the correct interconnection method is one of the most critical decisions in solar system design. The EG4 18kPV supports multiple configurations, each with specific NEC requirements. For a comprehensive overview, see our guide on US electrical panel types for solar interconnection.

Back fed Breaker Configuration (NEC 705.12)

Back fed breakers represent the most cost-effective and straightforward interconnection method for many residential installations. For detailed wiring guidance, review how to wire solar panels to a breaker box. Specific conditions must be met:

- The panel bus bar must be rated for 225A, OR the main breaker must be downsized to 175A

- Maximum critical loads subpanel size with this configuration is 70A

- Whole home backup is NOT achievable with back fed breaker configuration

NEC Code Formula: The sum of the main service breaker plus 125% of the inverter output rating cannot exceed 120% of the bus bar rating.

Calculation Example: For a 200A panel with a 225A bus bar: 200A + (50A x 1.25) = 262.5A. This exceeds 225A x 1.20 = 270A… Wait, that actually works! However, if your bus bar is only rated for 200A, 200A x 1.20 = 240A, and 200A + 62.5A = 262.5A exceeds this limit, requiring a main breaker downsize to 175A.

Supply-Side Tap Configuration

When a back fed breaker won’t work due to bus bar limitations, a supply-side solar connection offers an alternative. This configuration requires careful consideration:

- Must tap between the utility meter and main breaker

- Requires accessible tapping point (KUP-L type tap or equivalent)

- Professional electrician installation strongly recommended

- Utility power shutdown required during installation

Warning: There is a real danger of overloading service entrance wires with supply-side taps. You will essentially be adding loads to a possibly already fully loaded service entrance. Only proceed under advisement of your electrician and/or inspector. Reference NEC 220 for load calculations.

Feeder Tap Configuration (Ideal for Whole Home Backup)

Feeder taps represent the ideal and safest method for achieving whole-home backup with full solar back feed and battery charging capability:

- Provides full solar back-feed capability (12 kW from inverter)

- Enables full battery charging capacity (250A)

- Supports true whole-home backup operation

- 200A main service breaker must be stand-alone (not a load center)

- No loads permitted between utility meter and feeder tap

Recommended Hardware: Ilsco KUP-L-Taps with proper torque specifications, or Polaris/Burndy Insulated Multi Tap Connectors (requiring two torque applications – initial and 24 hours later).

Recommended Breaker Ratings

Wiring Specifications for Plan Sets

Proper wire sizing ensures safe operation, code compliance, and successful inspections. For comprehensive guidance on wire gauge selection, see our solar conductor sizing per NEC standards guide. The following specifications should appear on your plan set wiring schedule.

AC Wiring Requirements

Battery Wiring Requirements

PV Wiring Requirements

For detailed information on cable selection, review our comprehensive solar cable types guide:

Ground-Neutral Bonding (Critical for Inspectors)

Ground-neutral bonding is one of the most common areas of confusion and inspection failures. Understanding the EG4 18kPV’s architecture is essential for proper system design. This topic is covered extensively in NEC codes for solar and storage systems.

Inverter Architecture

The EG4 18kPV uses a common neutral architecture with the following characteristics:

- The neutral line is a solid connection between AC input and AC output

- The neutral line between AC input and output is NEVER disconnected

- The inverter does NOT generate a ground-neutral bond internally

- AC grounds, PV grounds, and inverter case are all permanently tied together

System Bonding Requirements

Critical Rule: The system must have ONE and ONLY ONE ground-neutral bond.

- This bond is typically located at the first grid system disconnect (system bonding jumper)

- For most residential installations, this is at the main service panel

- Do NOT add additional ground-neutral bonds in subpanels or at the inverter

- Verify existing bonding before finalizing system design

Rapid Shutdown (RSD) Compliance

Rapid shutdown is a mandatory safety requirement for most solar installations. The EG4 18kPV includes integrated RSD functionality that simplifies compliance. For complete details on RSD requirements, see our rapid shutdown compliance roadmap.

NEC 2017 & 2020 Compliance (690.12)

The EG4 18kPV meets rapid shutdown requirements through its built-in system. For labeling requirements, reference the NEC code requirements for PV labeling:

- Built-in RSD transmitter module located behind the internal circuit board

- PV conductor voltage reduced to less than 30V within 30 seconds of activation

- An external RSD initiator switch required at readily accessible outdoor location

- Compatible with standard RSD switch/button configurations

Plan Set Documentation Requirements

Your plan set should include the following RSD-related documentation:

- RSD switch location clearly marked on site plan

- RSD initiator wiring diagram showing connection to inverter

- Reference to NEC 690.12 compliance in plan notes

- Manufacturer’s RSD specification sheet or compliance letter

Physical Specifications for Installation Planning

Understanding the physical requirements of the EG4 18kPV ensures proper installation location selection and helps prevent costly site modifications.

Dimensions & Weight

Installation Note: Due to the 121+ lb weight, two or more people are required for safe installation.

Clearance Requirements

Proper clearances ensure adequate heat dissipation and maintenance access:

- A minimum of 7.87 inches (20 cm) clearance required on ALL sides

- Must NOT be positioned in direct sunlight

- LCD screen must be protected from UV exposure

- The inverter must be mounted upright on a vertical surface

Mounting Specifications

The inverter must be mounted on a vertical, solid, non-combustible surface such as brick, concrete, or equivalent:

- Accommodates stud spacing: 12-16 inches (305-406 mm)

- Drill hole diameter: 5/16 inch (8 mm) for expansion bolts

- Minimum hole depth: 2 inches (50 mm)

- Expansion bolts required for brick/concrete installations

AC Coupling for Existing Solar Systems

The EG4 18kPV can integrate with existing grid-tied solar systems through AC coupling, making it an excellent choice for adding battery backup to systems without replacing existing inverters.

AC Coupling Specifications

- Maximum AC-coupled solar input: 90A / 21.6kW

- Combined with MPPT inputs: Up to 33.6 kW total grid back-feed potential

- The existing system connects to the inverter’s GEN port

- Requires a UL1741SA-compliant feed-in inverter for proper frequency-watt response

Permit Considerations for AC-Coupled Systems

- A feeder tap or supply-side tap typically required for full back-feed capacity

- Frequency-shifting power reduction mechanism maintains micro-grid balance

- The plan set must show both existing and new equipment

- Combined system capacity calculations required

How Frequency-Shifting Works: When the 18kPV needs to reduce output from the AC-coupled inverter (such as when batteries are full), it shifts its output frequency slightly upward. UL1741SA-compliant inverters respond by reducing their output power, maintaining system balance without communication wiring between inverters.

Common AHJ Questions & Documentation Tips

Anticipating inspector questions and providing comprehensive documentation significantly improves approval rates and reduces revision cycles. Understanding solar engineering requirements for permits will help streamline your approval process.

Frequently Requested Documents

Include these documents with your permit submittal package:

- UL 1741 Certificate of Compliance

- Complete specification sheet with all electrical ratings

- Single-line diagram (EG4 provides templates)

- System wiring diagrams specific to your configuration

- Battery compatibility list

- Anti-islanding certification documentation

Common Inspector Concerns

Be prepared to address these frequently raised issues:

- Ground-neutral bonding location and verification

- Rapid shutdown compliance and initiator location

- Breaker sizing calculations per NEC 705.12

- Service entrance conductor capacity verification

- CT/Meter placement for zero-export verification (if applicable)

Pro Tips for Faster Approvals

- Include EG4’s pre-made wiring diagrams with your submittal – they’re professionally drafted and inspector-friendly

- Reference specific NEC articles in plan notes (690.12, 705.12, etc.)

- Provide manufacturer’s derate letter if installation is in high-temperature environment

- For California installations, include SGIP Public Equipment List verification

- Pre-emptively include load calculations showing NEC 705.12 compliance

Conclusion

The EG4 18kPV All-In-One Hybrid Inverter offers a compelling combination of capability and code compliance that simplifies the solar permitting process. With comprehensive UL certifications, built-in rapid shutdown functionality, and flexible interconnection options, this inverter addresses the requirements of virtually any residential or light commercial installation.

Key specifications that permit offices and AHJs need to see are readily available in EG4’s documentation library, and the inverter’s design inherently addresses many common code compliance concerns. Whether you’re pursuing a simple back fed breaker installation or a complex whole-home backup system with AC coupling, the technical specifications outlined in this guide provide the foundation for successful permit applications.

For homeowners and DIYers, understanding these specifications helps you communicate effectively with your installer and permit office. For professional installers, this guide serves as a comprehensive reference for plan set preparation and pre-inspection checklists. The EG4 18kPV’s robust certification portfolio and well-documented specifications make it an excellent choice for projects where permitting efficiency matters.

Need professional assistance with your solar permit application? Solar Permit Solutions specializes in preparing comprehensive plan sets and permit documentation for residential and commercial solar design installations featuring EG4 equipment. For off-grid solar system design, our team understands the specific requirements of AHJs nationwide and can help streamline your approval process.

FAQs

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

The EG4 18kPV carries UL 1741 SB certification (Rule 21 compliant), ETL and cETL listing, CSA 22.2.107.1 and CSA 22.2.330 compliance, and UL 9540 energy storage certification. It also meets IEEE 1547:2018 interconnection standards, California Rule 21 Phase I, II, and III requirements, and Hawaii Rule 14H specifications. These certifications satisfy permit requirements across all U.S. jurisdictions.

Yes, the EG4 18kPV includes a built-in rapid shutdown transmitter module that meets NEC 2017 and NEC 2020 Section 690.12 requirements. The system reduces PV conductor voltage to less than 30V within 30 seconds of activation. An external RSD initiator switch must be installed at a readily accessible outdoor location to complete the compliant installation.

Breaker sizing depends on your interconnection method. For whole-home backup with feeder tap configuration, use a 200A maximum breaker at 240VAC. For partial load backup, a 100A breaker at 240VAC is recommended. PV input requires a 600 VDC/20 A breaker, and generator connections require a 100 A breaker at 240 VAC. Always verify your panel bus bar rating meets NEC 705.12 requirements before installation.

Yes, the EG4 18kPV supports AC coupling with existing grid-tied solar systems through its GEN port. It accepts up to 90A or 21.6kW of AC-coupled solar input. Combined with its MPPT inputs, the system can achieve up to 33.6 kW total grid backfeed capacity. Your existing inverter must be UL1741SA compliant for proper frequency-watt response during AC-coupled operation.

Battery wire sizing depends on your configuration and distance. For two battery sets within 10 feet, use 1/0 AWG wire. For two sets up to 20 feet, use 2/0 AWG. Single-set configurations require 4/0 AWG for 10 feet maximum distance or 250 kcmil for up to 20 feet. All battery wiring must be rated for 90°C and torqued to manufacturer specifications of 165-275 in-lbs depending on terminal size.

The EG4 18kPV does not generate an internal ground-neutral bond. The system uses a common neutral architecture where the neutral line maintains a solid connection between AC input and output. Your installation must have exactly ONE ground-neutral bond, typically located at the main service panel. Do not add additional bonds at subpanels or at the inverter to avoid inspection failures and safety hazards.

The EG4 18kPV accepts a maximum of 18 kW of utilized solar power across three MPPTs, with a recommended maximum input of 21 kW. MPPT-1 handles up to 25A usable current with two parallel string inputs, while MPPT-2 and MPPT-3 each accept 15A with single string inputs. The DC input voltage range spans 100-600 VDC, with full power MPPT operation between 230-500 VDC.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...

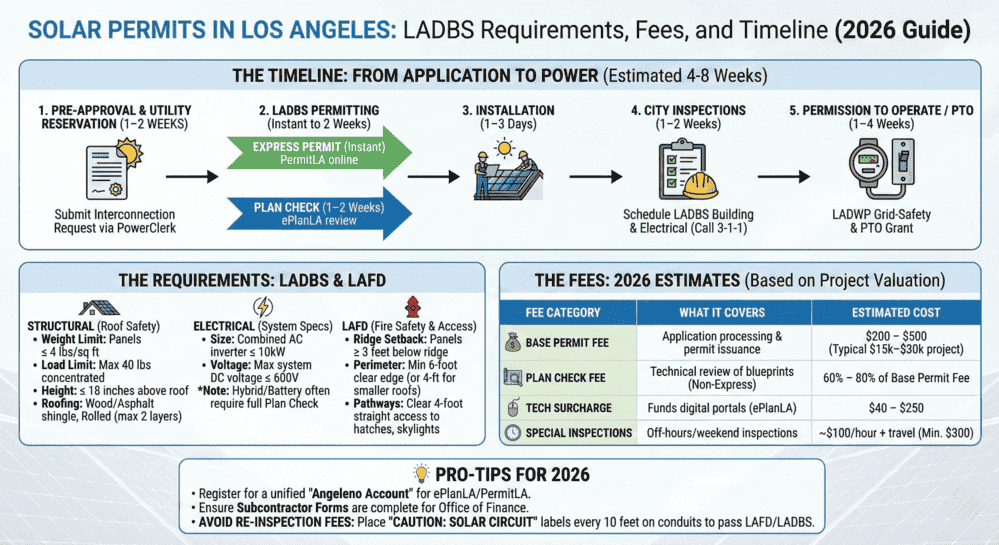

Solar Permits in Los Angeles: LADBS Requirements, Fees, and Timeline (2026 Guide)

Quick Answer: Solar permits in Los Angeles are issued by LADBS and require LAFD ...