If you’re planning a solar installation with battery backup, you’ve probably encountered two separate challenges: understanding inverter specifications and navigating the permit approval process. The EG4 12kPV All-In-One Hybrid Inverter has become a popular choice for residential and light commercial projects, but knowing the specs is only half the battle. Your local Authority Having Jurisdiction (AHJ) needs specific documentation that proves your system meets electrical codes and safety standards.

This guide bridges that gap. We’ll break down every critical specification from the EG4 12kPV data sheet and show you exactly how each spec translates to permit requirements, plan set documentation, and utility interconnection approval. Whether you’re a homeowner tackling a DIY project, a seasoned installer, or somewhere in between, this comprehensive resource will help you understand both the technical capabilities and the permitting pathway for your EG4 12kPV installation.

What Is the EG4 12kPV All-In-One Hybrid Inverter?

The EG4 12kPV is a 48V split-phase hybrid inverter/charger designed to handle multiple energy scenarios from a single unit. It accepts up to 12kW of solar input through dual MPPT charge controllers while delivering 8kW of continuous AC output power. The “hybrid” designation means this inverter can operate in grid-tied mode (selling excess power back to the utility), off-grid mode (complete independence from the grid), or a combination where it prioritizes solar and battery while using grid power as backup.

The unit carries model numbers IV-8000-HYB-AW and IV-8000-HYB-AW-00, with SKU EG4INV12KPV00V2. For larger installations, up to 10 units can be paralleled together for a combined output of 80 kW, making it suitable for everything from single-family homes to small commercial buildings.

From a permitting perspective, the operating mode you choose affects how your AHJ classifies the installation. Grid-interactive systems require utility interconnection agreements and specific anti-islanding certifications. Off-grid systems may have different structural and electrical requirements. Parallel configurations involving multiple inverters need additional documentation for load calculations, conductor sizing, and disconnect placement. Understanding these distinctions early helps you prepare the right permit package from the start.

Key Technical Specifications for Permit Applications

Every specification on the EG4 12kPV data sheet serves a purpose in your permit application. Let’s examine the critical specs by category and explain exactly how each one appears in your plan set documentation.

AC Input & Output Specifications

The AC side of your inverter connects to your electrical panel and, in grid-tied installations, to the utility grid. These specifications determine breaker sizing, wire gauge requirements, and compatibility with your existing electrical service. Understanding US electrical panel types for solar interconnection helps ensure your system integrates properly with your home’s electrical infrastructure.

The split-phase design requires L1, L2, and neutral connections, which your electrical single-line diagram must clearly show. The 120/208 VAC option allows installation in commercial settings with 3-phase service where you derive split-phase from two legs of the 3-phase system.

For peak power handling, the EG4 12kPV can surge significantly above its continuous rating: 16kW for half a second, 12kW for one second, 10kW for one minute, and 8.8kW for twelve minutes. This surge capability means the inverter can start large motor loads like air conditioners (up to 5-ton units) without requiring soft-start devices. The 195A Locked Rotor Amps (LRA) rating confirms this capability and should be noted on your plan set when documenting motor load compatibility.

PV Input Specifications

The DC side specifications govern how you configure your solar array. Proper string sizing is one of the most scrutinized elements of any solar permit application, and these specs provide the boundaries for your calculations.

String sizing calculations represent the most technical portion of your permit application. You must demonstrate that your array voltage stays within safe limits across all temperature conditions your location experiences. For detailed guidance on these calculations, review our resource on NEC 690.7 solar voltage limits and calculation methods.

For cold temperature calculations, use the formula: VOC (at STC) × Temperature Coefficient × Number of Modules in Series. Your result must stay below 600 VDC absolute maximum, but best practice targets the 500 VDC MPPT operating maximum to provide a safety margin.

For hot temperature calculations, your string voltage at maximum power (VMP adjusted for temperature) must remain above 120 VDC to ensure the MPPT can track properly. Falling below this threshold means reduced or zero power production during hot afternoons when you need it most.

EG4 provides an official string sizing tool at their website that automates these calculations. Including a screenshot or printout from this tool strengthens your permit application by showing you used manufacturer-approved methods.

Battery Specifications

Energy storage systems add another layer of permitting requirements, particularly regarding fire safety and electrical protection. The EG4 12kPV works with both lead-acid and lithium battery chemistries, though lithium installations face additional scrutiny in most jurisdictions.

The 167A maximum battery current dictates significant wire sizing requirements. At 48V nominal, this represents roughly 8kW of power flow, requiring cables sized for continuous duty at this amperage plus appropriate overcurrent protection devices.

Lithium battery installations typically require UL 9540 certification for the complete energy storage system, not just individual components. EG4 offers UL 9540 certified configurations pairing the 12kPV with their WallMount Indoor and WallMount All Weather battery products. Using these pre-certified combinations significantly simplifies the permitting process compared to assembling components from different manufacturers.

Indoor lithium battery installations may trigger additional fire code requirements depending on your jurisdiction. Some AHJs require fire separation, ventilation specifications, or fire suppression systems for indoor lithium storage above certain capacity thresholds. Check with your local fire marshal early in the planning process.

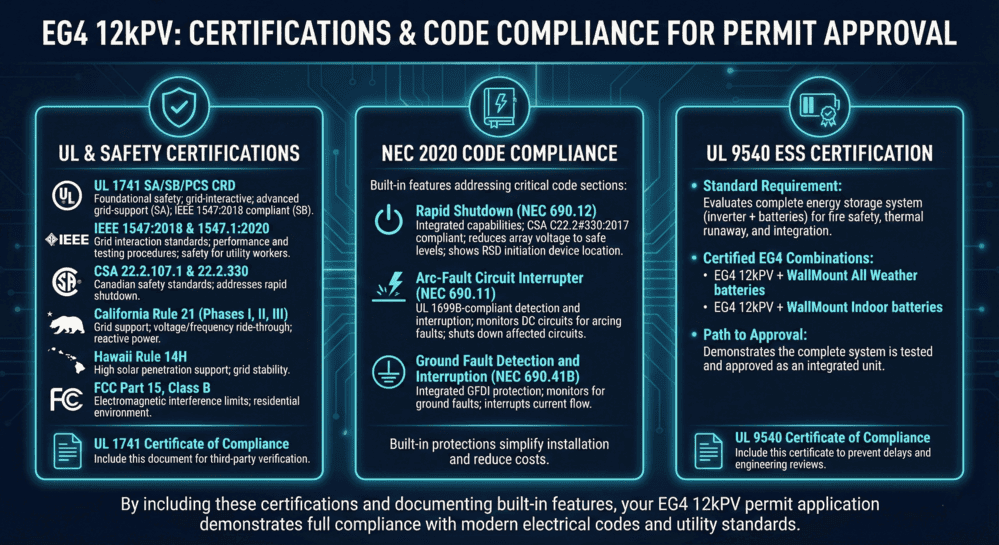

Certifications & Code Compliance for Permit Approval

Modern solar permits require extensive documentation proving your equipment meets national electrical codes and utility interconnection standards. The EG4 12kPV carries a comprehensive certification portfolio that addresses virtually every requirement you’ll encounter.

UL & Safety Certifications

The following certifications appear on the EG4 12kPV specification sheet and should be referenced in your permit application:

UL 1741 SA, SB, PCS CRD – This is the foundational safety certification for grid-interactive inverters in North America. The SA (Supplement A) designation indicates compliance with advanced grid-support functions required by modern interconnection standards. The SB designation confirms compliance with IEEE 1547:2018. The PCS CRD (Power Control Systems Certification Requirement Decision) confirms the inverter meets the latest testing protocols.

IEEE 1547:2018 and IEEE 1547.1:2020 – These standards govern how distributed energy resources interact with the electrical grid. IEEE 1547:2018 establishes performance requirements while IEEE 1547.1:2020 defines the testing procedures. Together, they ensure the inverter responds appropriately to grid disturbances and doesn’t create safety hazards for utility workers. The National Renewable Energy Laboratory provides comprehensive IEEE 1547 implementation guidance for utilities and installers.

CSA 22.2.107.1 and CSA 22.2.330 – Canadian safety standards that also apply to installations in the United States. The 330 standard specifically addresses rapid shutdown requirements.

California Rule 21 (Phase I, II, III) – Required for any grid-connected installation in California. This certification confirms the inverter supports advanced grid functions, including voltage and frequency ride-through, ramp rate controls, and reactive power support. For California installations, our solar design services in Concord, CA can help streamline your permit package.

Hawaii Rule 14H – Similar to California Rule 21, this certification is mandatory for installations in Hawaii, where high solar penetration creates unique grid stability challenges.

FCC Part 15, Class B – Confirms the inverter meets electromagnetic interference limits for residential environments, preventing interference with televisions, radios, and other electronic equipment.

When submitting your permit application, include the UL 1741 Certificate of Compliance. This document provides third-party verification that the specific model you’re installing has passed all required safety tests. You can verify equipment certifications through the California Energy Commission’s Solar Equipment Lists.

NEC 2020 Code Compliance

The National Electrical Code (NFPA 70) establishes installation requirements that your AHJ enforces. The EG4 12kPV includes built-in features that address the most critical solar-specific code sections. For a comprehensive overview, see our guide to Article 690 updates for installers under NEC 2023.

Rapid Shutdown (NEC 690.12) – The EG4 12kPV has integrated rapid shutdown capabilities compliant with NEC 2020 requirements and CSA C22.2#330:2017. When the RSD initiation device activates, the inverter reduces array voltage to safe levels within the required timeframe. Your plan set must show the RSD initiation device location (typically at the main service panel or a readily accessible exterior location) and indicate how it communicates with the inverter. Review our NEC 690.56(C) rapid shutdown labeling guide for proper documentation.

Arc-Fault Circuit Interrupter (NEC 690.11) – The inverter includes UL 1699B-compliant arc-fault detection and interruption. This protection monitors the DC circuits for the electrical signatures of arcing faults (damaged wires, loose connections, degraded insulation) and shuts down the affected circuit before a fire can start. Our detailed arc-fault protection compliance guide covers documentation requirements.

Ground Fault Detection and Interruption (NEC 690.41B) – Integrated GFDI protection monitors for ground faults in the array and interrupts current flow if detected. This feature must be documented on your plan set with appropriate notation showing the protection scheme.

These built-in protections eliminate the need for separate external devices, simplifying installation and reducing costs while ensuring code compliance.

UL 9540 ESS Certification

For installations including battery storage, UL 9540 certification has become the standard requirement across most jurisdictions. This certification evaluates the complete energy storage system (inverter plus batteries) for fire safety, thermal runaway prevention, and proper system integration.

EG4 has obtained UL 9540 certification for specific inverter-battery combinations:

- EG4 12kPV paired with WallMount All Weather batteries

- EG4 12kPV paired with WallMount Indoor batteries

Using these certified combinations provides a clear pathway to permit approval. The UL 9540 Certificate of Compliance demonstrates that the complete system has been tested and approved as an integrated unit, not just individual components that might not work safely together.

If your jurisdiction requires UL 9540 certification, including this certificate with your permit application can prevent delays and additional engineering review requirements.

Solar Permit Solutions

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Creating Permit-Ready Plan Sets with EG4 12kPV Specifications

Understanding specifications is essential, but translating them into permit-ready documentation is where projects succeed or stall. Here’s how to create plan sets that incorporate EG4 12kPV specifications correctly. For comparison with a higher-capacity option, see our guide to EG4 18kPV inverter specifications and permitting.

Required Documents for Solar Permit Applications

A complete permit package typically includes five core documents, though requirements vary by jurisdiction:

Site Plan – Shows equipment locations, including inverter placement, array position, AC and DC disconnect locations, meter location, and required setbacks and access pathways. For the EG4 12kPV, note the NEMA 4X enclosure rating that permits installation in protected outdoor locations.

Electrical Single-Line Diagram – The most technically detailed document, showing how all components connect electrically. This diagram must reference specific equipment specifications.

String Sizing Calculations – Mathematical proof that your array configuration stays within inverter limits across all operating temperatures.

Equipment Specifications – Manufacturer spec sheets and certification documents. Include the complete EG4 12kPV specification sheet and UL 1741 Certificate of Compliance from the EG4 Electronics documentation library.

Structural Calculations – Required for roof-mounted arrays to prove the structure can support the additional load. While this primarily concerns the array rather than the inverter, mounting locations for the 110-pound inverter may require structural verification for wall-mounted installations. Review our guide on solar engineering requirements for permits to understand when PE stamps are required.

Electrical Single-Line Diagram Requirements

Your single-line diagram should incorporate these EG4 12kPV specifications:

AC Connection Details – Show the connection from the inverter to your electrical panel with appropriate conductor sizing for 33.3A continuous current at 240VAC. A 40A breaker represents the minimum size, though your AHJ may require larger based on local amendments. For guidance on breaker connections, see our article on wiring solar panels to a breaker box.

DC Disconnection – The EG4 12kPV includes an integrated PV disconnect, which should be noted on your diagram. Depending on your jurisdiction and array location, additional external DC disconnects may be required.

PV Array Configuration – Show how your strings connect to the two MPPTs, with string voltage and current specifications. Label each string with its calculated VOC (temperature-corrected) and ISC values.

Battery Connection – If including energy storage, show the battery bank connection with appropriate overcurrent protection devices sized for the 167A maximum charge/discharge current.

RSD System – Indicate the rapid shutdown initiation device location and its connection to the inverter system. Note the NEC 690.12 compliance.

Utility Connection – Show the meter location and point of common coupling with the utility grid. Note the IEEE 1547:2018 compliance for interconnection.

String Sizing Documentation

String sizing calculations require location-specific temperature data and module specifications. Your documentation should show:

Module Specifications Used – VOC, VMP, ISC, IMP, and temperature coefficients from your selected panel’s data sheet.

Temperature Extremes – Record low and record high temperatures for your installation location, typically available from ASHRAE data or local weather records.

Voltage Calculations – Show the math for cold-temperature VOC (must stay below 600V, preferably below 500V) and hot-temperature VMP (must stay above 120V).

Current Calculations – Demonstrate that string current stays within the 25A per MPPT limit and 31A short circuit rating.

String Configuration Summary – Final configuration showing number of modules per string, number of strings per MPPT, total array wattage, and calculated voltage range.

Including a printout from the EG4 string sizing tool provides manufacturer-endorsed verification of your calculations.

Interconnection Application Requirements

Utility interconnection requires documentation beyond the building permit. Your interconnection package typically needs:

- UL 1741 Certificate of Compliance demonstrating grid-interactive safety certification

- IEEE 1547 compliance documentation confirming proper grid interaction behavior

- Manufacturer specification sheet with anti-islanding protection details

- System single-line diagram matching your permit drawings

- Site plan showing meter and point of interconnection

- Completed utility application forms with system specifications

For detailed documentation requirements, our solar interconnection agreement checklist covers everything you need. For a complete walkthrough, review our guide on how solar panels connect to the grid. The DSIRE database provides state-specific interconnection requirements and incentive information.

The EG4 12kPV supports advanced grid functions that utilities increasingly require: adjustable power factor (0.99 default with ±0.8 range), reactive power support for voltage regulation, and programmable export limiting for utilities that restrict backfeed. The zero export function proves particularly valuable in jurisdictions that prohibit or limit grid export, allowing you to use solar and battery power without feeding excess to the grid. When load-side connections aren’t feasible, supply-side tap connections offer an alternative interconnection method.

Installation Considerations That Affect Permitting

Physical installation requirements impact both permit approval and long-term system performance. The EG4 12kPV specifications define what’s possible; your installation must work within these parameters.

Physical Specifications & Mounting

The EG4 12kPV measures 29.5 × 20.5 × 11.2 inches (750 × 520 × 285 mm) and weighs 110 pounds (50kg). This substantial weight requires proper mounting consideration. Wall-mounted installations need structural verification that the wall can support this concentrated load, particularly for drywall-over-stud construction.

The NEMA 4X enclosure rating indicates protection against windblown dust and rain, hose-directed water, and corrosion. This rating permits installation in protected outdoor locations such as covered porches, carports, or weatherproof enclosures. Direct exposure to rain and extreme weather isn’t recommended despite the rating.

Plan sets should show inverter mounting location with appropriate clearances for ventilation and service access. The spec sheet indicates noise emission under 50 dB at 3 feet, roughly equivalent to a quiet conversation, making indoor installation feasible in utility rooms or garages without significant noise concerns.

Environmental Ratings

Operating conditions determine where you can install the inverter and whether any derating applies:

Temperature Range – The EG4 12kPV operates from -13°F to 140°F (-25°C to 60°C), covering virtually all inhabited climate zones. Installations in extreme environments should document expected temperature ranges.

Humidity Tolerance – 0-100% relative humidity tolerance means moisture shouldn’t affect operation, though condensation prevention through proper mounting location remains good practice.

Altitude Limitation – Maximum operating altitude of 6,561 feet (2,000 meters) means high-altitude installations above this threshold may require derating documentation. Colorado mountain communities and similar locations should verify altitude compliance.

Parallel System Configurations

For installations requiring more than 8kW output, the EG4 12kPV supports paralleling up to 10 units. The “Share Battery” feature simplifies multi-inverter installations by coordinating battery charging and discharging across units without complex external controls.

Parallel configurations require additional permit documentation:

Expanded Single-Line Diagram – Show all inverter units with their interconnections, including parallel communication cables and coordinated AC connections.

Load Balance Calculations – The system handles up to 4,000 W of load imbalance between phases for 30 minutes, but your documentation should show expected load distribution.

Conductor Sizing – Multiple inverters mean higher current capacity requirements for feeders and service conductors.

Disconnect Requirements – Each inverter may require individual disconnecting means depending on your AHJ’s interpretation of NEC requirements.

Conclusion

The EG4 12kPV offers a compelling combination of technical capability and certification coverage that streamlines the path from system design to permit approval. Its comprehensive safety certifications (UL 1741, IEEE 1547, NEC 2020 compliance) address the documentation requirements that AHJs and utilities demand, while built-in features like rapid shutdown, arc-fault protection, and ground-fault monitoring eliminate the need for external safety devices.

For your permit application, download the current specification sheet (version 1.0.8) directly from the EG4 website along with the UL 1741 Certificate of Compliance. Use the EG4 string sizing tool to generate manufacturer-verified calculations for your array configuration. If including battery storage, obtain the UL 9540 certificate for your specific inverter-battery combination. The U.S. Department of Energy’s solar tax credit guide provides information on federal incentives that may apply to your installation.

Contact your local AHJ early in the planning process to confirm specific requirements for your jurisdiction. While the certifications and specifications covered in this guide apply nationally, local amendments and interpretations vary. A preliminary conversation with your permit office can identify any unique requirements before you invest time in detailed plan sets. For Texas installations, our solar permit services in Houston provide local expertise to navigate regional requirements.

Whether you’re a homeowner navigating your first solar permit or an installer documenting another professional installation, the EG4 12kPV’s thorough certification portfolio and clear specifications provide the foundation for successful permit approval. Working with a NABCEP-certified installer ensures professional expertise throughout the process. Understanding average solar permit timelines by state helps set realistic expectations for your project schedule.

FAQs

Does the EG4 12kPV have a built-in rapid shutdown?

Yes. The inverter includes integrated rapid shutdown capabilities compliant with NEC 2020 Section 690.12 and CSA C22.2#330:2017. When the RSD initiation device activates, the inverter reduces PV circuit voltage to safe levels within required timeframes. Your plan set must show the initiation device location and indicate this built-in compliance.

What’s the maximum solar array size for the EG4 12kPV?

The inverter utilizes up to 12 kW of solar input, with EG4 recommending a maximum array size of 15 kW. The 25% oversizing allowance accounts for real-world conditions where arrays rarely produce nameplate power. String voltage must stay within the 120-500 VDC MPPT operating range (600 VDC absolute maximum), and string current must not exceed 25A per MPPT.

Skip the Permit Headaches

We design plan sets that pass inspection the first time. Code-compliant, PE-stamped, accepted by AHJs nationwide.

Frequently Asked Questions

Yes. The EG4 12kPV carries UL 1741 SA/SB certification and complies with IEEE 1547:2018, the current standards for grid-interactive inverters throughout North America. Additional certifications for California Rule 21 and Hawaii Rule 14H cover the most stringent state-level requirements. Include the UL 1741 Certificate of Compliance with your permit and interconnection applications.

The maximum continuous output current is 33.3A at 240VAC, requiring a minimum 40A breaker for the backfed connection to your electrical panel. Your specific installation may require larger sizing based on wire length, ambient temperature, or local code amendments. The breaker must be identified as backfed and secured per NEC requirements for inverter connections.

Yes. The inverter includes integrated rapid shutdown capabilities compliant with NEC 2020 Section 690.12 and CSA C22.2#330:2017. When the RSD initiation device activates, the inverter reduces PV circuit voltage to safe levels within required timeframes. Your plan set must show the initiation device location and indicate this built-in compliance.

The inverter utilizes up to 12 kW of solar input, with EG4 recommending a maximum array size of 15 kW. The 25% oversizing allowance accounts for real-world conditions where arrays rarely produce nameplate power. String voltage must stay within the 120-500 VDC MPPT operating range (600 VDC absolute maximum), and string current must not exceed 25A per MPPT.

Yes. UL 9540 ESS certification is available when pairing the EG4 12kPV with EG4 WallMount Indoor batteries or WallMount All Weather batteries. These pre-certified combinations simplify permit approval for energy storage installations. Include the UL 9540 Certificate of Compliance with your permit application when installing battery storage.

SPS Editorial Team

Solar Permit Solutions

Solar Permit Solutions provides professional solar permit design services for residential, commercial, and off-grid installations across all 50 states. Our team ensures permit-ready plan sets delivered fast.

Related Articles

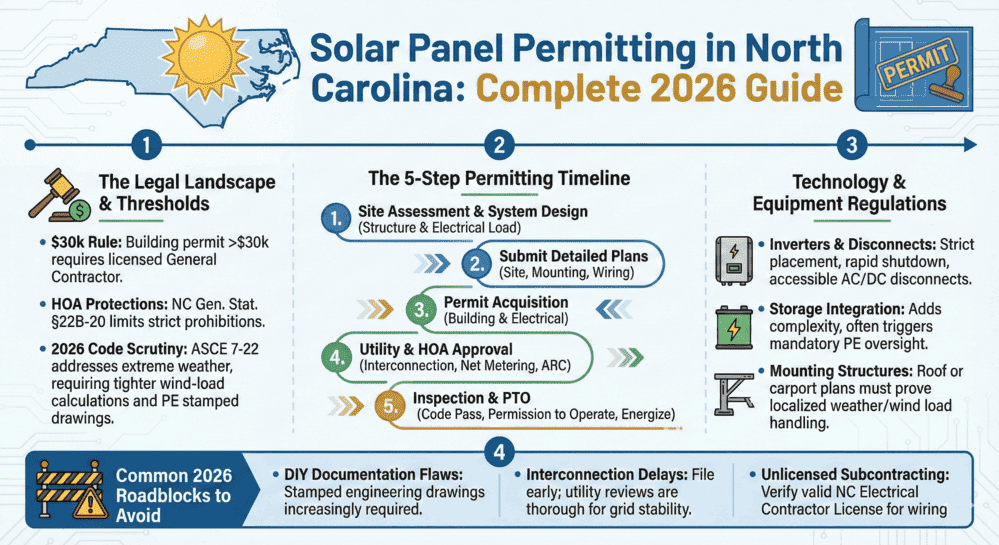

New 2026 North Carolina Solar Permit Guide: Duke Energy & Storage Rules

Learn North Carolina solar panel licensing and permitting requirements. Discover...

Section 25D Expiration: Homeowner Options In 2026

The Section 25D Residential Clean Energy Credit, which covered 30% of residentia...

Solar Permits In Arizona: Phoenix, Tucson, Maricopa County, And Mesa Requirements (2026 Guide)

Arizona solar permitting at a glance: Arizona HB2301 now requires every municipa...